Steel & Aluminium | Kirloskar Pneumatic - KPCL

Steel & Aluminium

Powering progress by strengthening resilience

As steel builds the world, while aluminium propels it forward, the steel and aluminium industry plays an essential role in building a stronger, lighter and more sustainable world.

At Kirloskar Pneumatic, we use compressed air to power this vision by providing clean, dry instrument air for precision operations and powering blast furnaces. Supporting air separation plants, our solutions help enable oxygen, nitrogen and argon production.

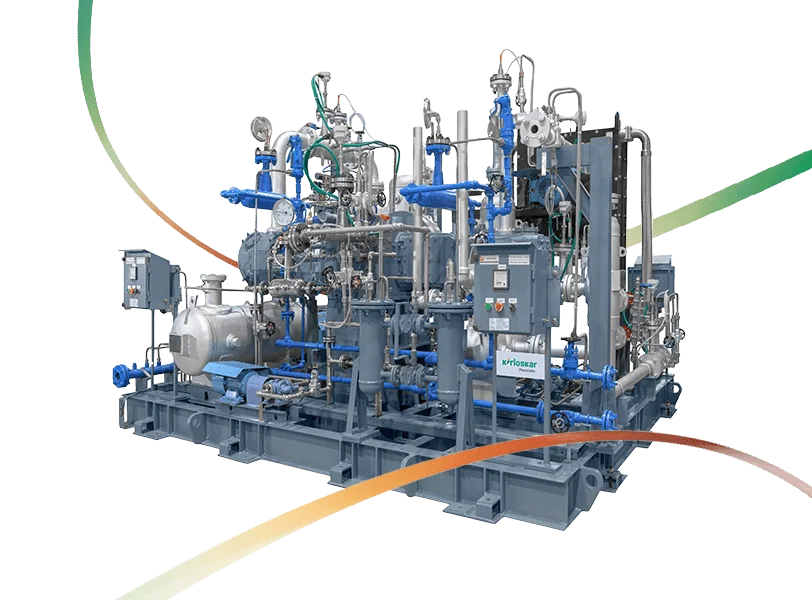

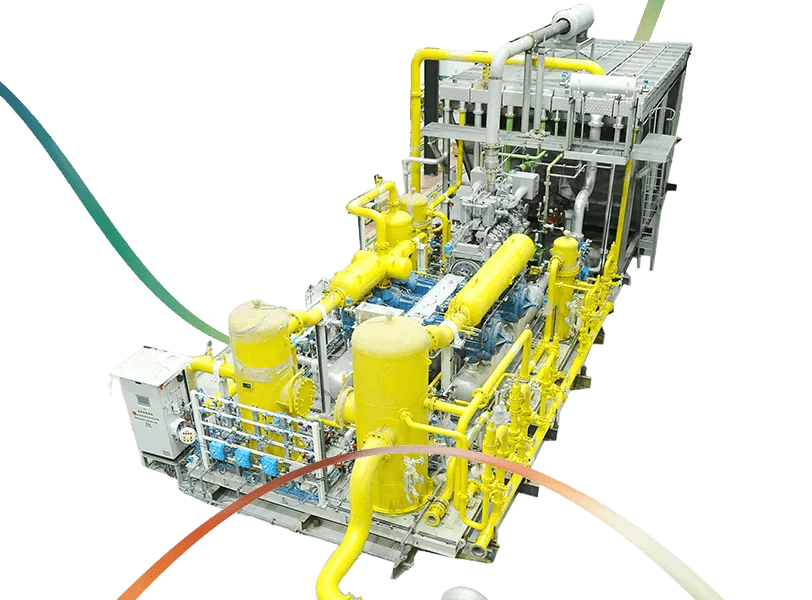

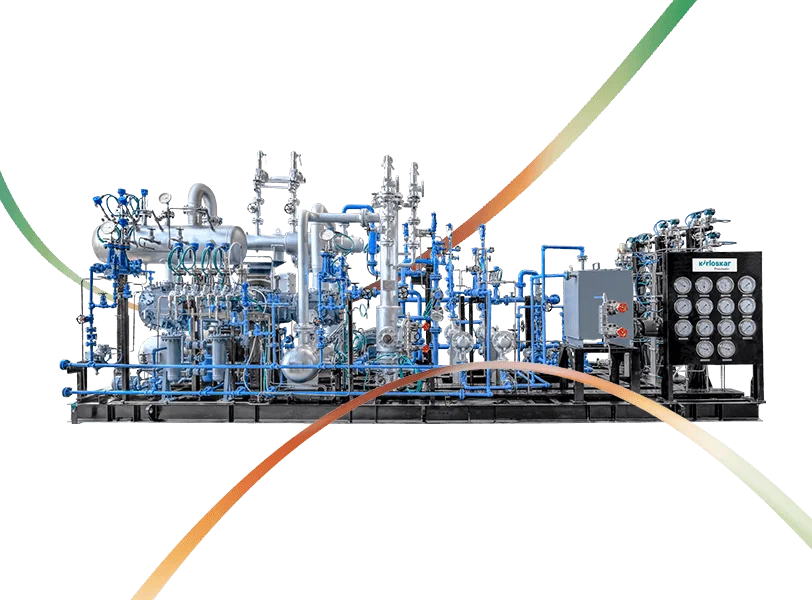

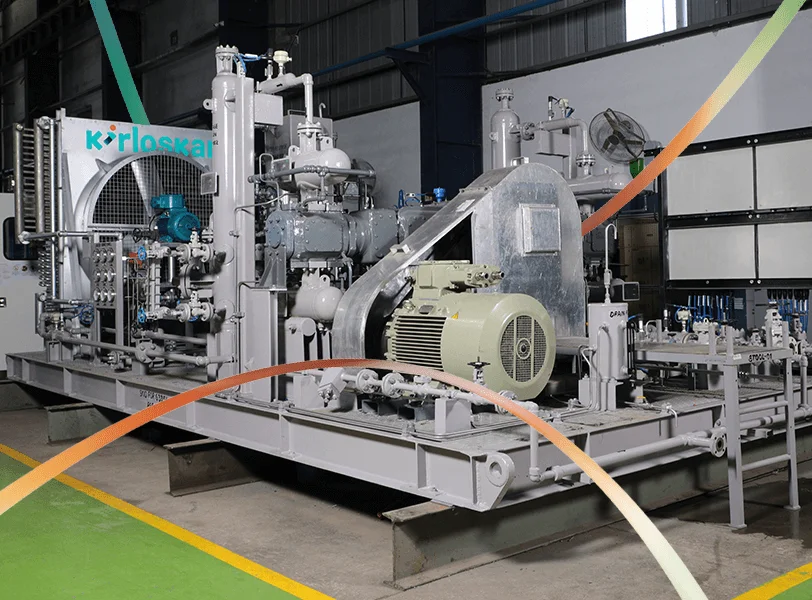

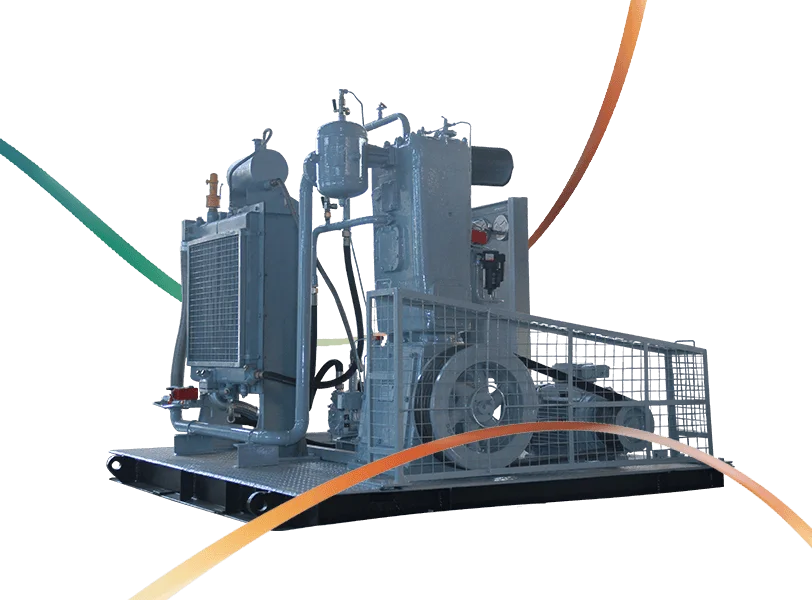

To support the evolving needs of the industry, our Air Compressor Division delivers robust solutions, ranging from oil-injected electric screw compressors to centrifugal and reciprocating gas compressors, including horizontal balanced opposed models, we ensure consistent performance in high-demand environments.

Our Air Conditioning and Refrigeration systems, including steam, hot water, exhaust, and direct-fired double-effect vapour absorption chillers, offer efficient cooling for critical industrial processes, helping maintain optimal operating conditions.

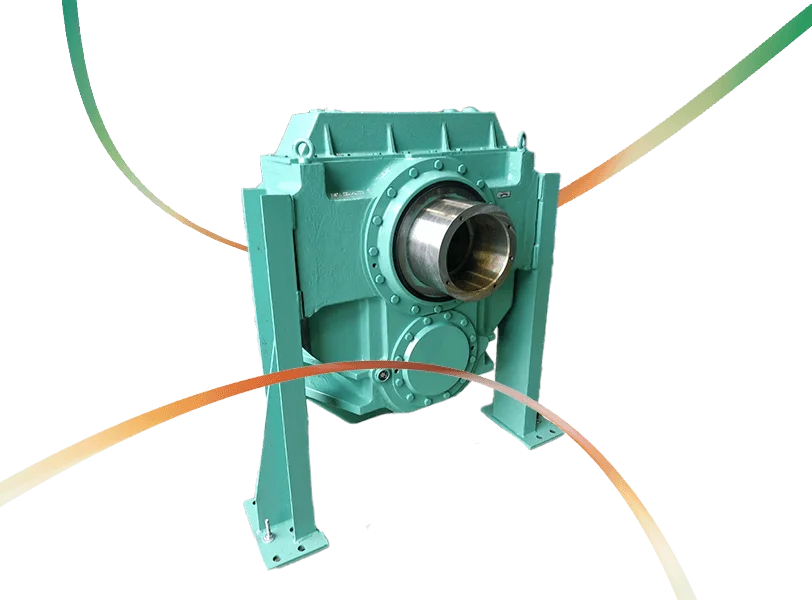

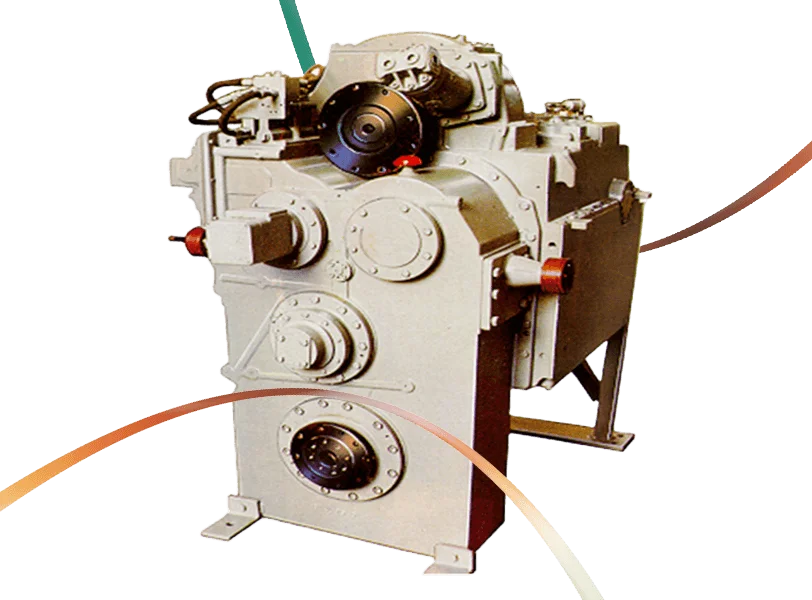

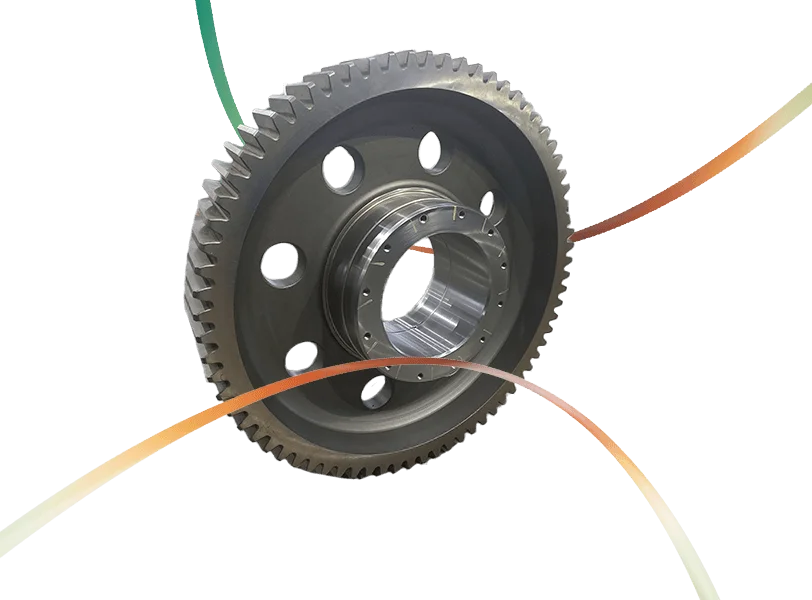

Through our Transmission solutions, featuring precision-engineered gears and pinions, helical and bevel gearboxes, high-speed gearboxes, planetary drives, and specialised railway transmissions, we ensure reliable power delivery and enhanced operational control.

At Kirloskar Pneumatic, not only do we support the steel and aluminium industry, we enable its transformation through resilient, future-ready engineering.

STEEL & ALUMINIUM

Powering progress by strengthening resilience

As steel builds the world, while aluminium propels it forward, the steel and aluminium industry plays an essential role in building a stronger, lighter and more sustainable world.

At Kirloskar Pneumatic, we use compressed air to power this vision by providing clean, dry instrument air for precision operations and powering blast furnaces. Supporting air separation plants, our solutions help enable oxygen, nitrogen and argon production.

To support the evolving needs of the industry, our Air Compressor Division delivers robust solutions, ranging from oil-injected electric screw compressors to centrifugal and reciprocating gas compressors, including horizontal balanced opposed models, we ensure consistent performance in high-demand environments.

Our Air Conditioning and Refrigeration systems, including steam, hot water, exhaust, and direct-fired double-effect vapour absorption chillers, offer efficient cooling for critical industrial processes, helping maintain optimal operating conditions.

Through our Transmission solutions, featuring precision-engineered gears and pinions, helical and bevel gearboxes, high-speed gearboxes, planetary drives, and specialised railway transmissions, we ensure reliable power delivery and enhanced operational control.

At Kirloskar Pneumatic, not only do we support the steel and aluminium industry, we enable its transformation through resilient, future-ready engineering.

Asset Publisher

Choose Applications

Air Conditioning/Equipment Cooling | Control Room Cooling...

Wort Cooling | Air Conditioning/Equipment Cooling | Control Room Cooling...

Reactor Cooling | Coffee Extract Cooling | Recycled Bottle Cooling...

Pulp Cooling in Pasteurization | Cooling in Pasteurisation...

Wort Cooling | Air Conditioning/Equipment Cooling | Control Room Cooling...

Flare Gas Recovery | LNG | LPG | BOG | GTL | Aromatics...

Flare Gas Recovery | Process Control and Instrumentation | LNG | LPG | BOG...

Pharmaceutical Storage | Freeze Drying (Lyophilisation)...

Traction Motors

Drilling Operations | Pipeline Maintenance and Testing...

Drilling Operations | Pipeline Maintenance and Testing...

Sandblasting | Jack hammer | Excavation | DTH Drilling | Tunnelling...

Flare Gas Recovery | Fuel Gas Booster | Gas Gathering | Gas Booster...

Drilling Operations | Pipeline Maintenance and Testing...

Wort Cooling | Air Conditioning/Equipment Cooling | Control Room Cooling...

(Comfort Cooling) Air Conditioning | Air Conditioning/Equipment Cooling

Blowers and Fans | Pinion Stand | Roughing Mill | Ladle Tilters | Sizing Mill...

Speciality pumps and compressor drives | Co-generations turbines...

Steel Furnace Tilter | Turbine | Sugar Mill Drive

Sandblasting | Jack hammer | Excavation | DTH Drilling | Tunnelling...

Carbon Dioxide Liquefaction | Chemical Reactors Cooling...

Pharmaceutical Storage | Freeze Drying (Lyophilisation)...

Pharmaceutical Storage | Freeze Drying (Lyophilisation)...

Pharmaceutical Storage | Freeze Drying (Lyophilisation)...

Bulker and train unloading | Silo fluidization | Combustion air...

Chilled Water Plants | Refrigeration Plants

HVAC Plants

Chilled Water Plants | Refrigeration Plants | HVAC Plants

Chilled Water Plants | Refrigeration Plants | HVAC Plants

Chilled Water Plants | Refrigeration Plants | HVAC Plants

Wind Turbine

Shunting Locomotives Drives

Open Gears

Flare Gas Recovery | Fuel Gas Booster | Gas Gathering | Vapor Recovery...

Gas Grid Injection | Cascade Filling

NGV Filling

NGV Filling

Sandblasting | Jack hammer | Excavation | DTH Drilling | Tunnelling...

Drilling Operations | Pipeline Maintenance and Testing...

Flare Gas Recovery | LNG | LPG | BOG | GTL | Aromatics...

Asset Publisher

No results found

Roll adjusting drives control the roll gap and maintain accurate thickness and profile control of the rolled metal. The helical and bevel gearboxes are used to transmit power and torque in an effort to adjust the roll position and the gap between rolls. Helical gearboxes are used for applications that need high power transmission with smooth and quiet operations between parallel shafts. Bevel gearboxes are used to transfer power between intersecting shafts, usually at right angles.

Vanadium Pentoxide Recovery controls temperature for efficient chemical recovery processes.

Co-generations turbines generate electricity, with the waste heat from exhaust gases used for industrial processes or heating. Both, helical and bevel gearboxes play an integral role in transmitting power, usually in conjunction with each other.

Tilting furnaces are used for melting and pouring molten metal with tilting mechanisms used in the casting and die-casting process. Planetary drives are used to provide torque and control as per the requirements for tilting and rotating the steel furnace. The planetary drives are preferred due to their high-torque density, compact size and the ability to withstand challenging conditions of the steel industry.

Ladle Tilters are used for transferring and pouring molten metal from larger ladles using hydraulic systems. Helical and bevel gearboxes play an important role for power transmission and speed reduction. Helical gearboxes are preferred for their smooth and quiet operations, usually when transmitting power between parallel shifts. Bevel gearboxes are used to change direction of the power transmission at a right angle. Along with helical stages, the bevel gearbox helps in achieving high reduction ratios and an efficient torque transfer.

A roughing mill reduces the overall thickness of the steel while elongating its length. Helical gearboxes are used to transmit power between parallel shifts, primarily for high-speed, high-torque applications. Bevel gearboxes are used to transmit power at right angles.

Shunting locomotive drives utilise a combination of steel and aluminium to power coupling, brakes and other operational systems. The railway transmission for locomotives is integral to help control speed, torque and the direction of motion, ensuring efficient and safe shunting operations.

Kiln Gearboxes rotate large kilns to ensure proper material flow and prevent damage during operation. Helical and bevel gearboxes are used for power transmission and speed control, particularly for rotating kilns.

Shears cut and shape the metal, while coilers wind long rolled pieces into coils for storage and transport. Both, helical and bevel gearboxes play a key role in transmission and lowering of speed. Helical gearboxes transfer power between parallel shafts. Bevel gearboxes transmit power at 90 degrees. A combination of both offer a versatile solution for applications that require torque transfer and angularity.

In the mills, hot rolling processes metal at temperatures above its recrystallisation point, while cold rolling occurs below that point. Helical and bevel gearboxes are used to transfer power, change the speed and the direction of rotation.

Cooling bed transfer frames are essential for cooling hot metal products after rolling or casting for uniform cooling. Helical and bevel gearboxes are used to transfer power between shafts for efficient and robust operations.

Tube drawing involves drawing a tube through a die to reduce its diameter and wall thickness. Helical and bevel gearboxes are important to control the speed, torque and direction of motion required to draw steel tubes. Helical gearboxes are used to transmit power between parallel shafts. Bevel gearboxes are used for power transmission between intersecting shafts at right angles.

Straightening corrects distortions and bends for dimensional accuracy, using compressed air to power rollers. The helical and bevel gearboxes are used to transfer power and motion for bending and straightening steel products. Helical gearboxes are used for high-load applications with parallel shafts. Bevel gearboxes are used for power transmission between 90 degree shafts.

Reversing Mills ensure the precise thickness of metal sheets and are used in functions like roll bending, roll shape adjustment, and automatic gauge control. Helical gearboxes are used for their ability to handle high torque and loads, especially for parallel shaft transmissions. Bevel gearboxes are used to transfer power at right angles ensuring efficient torque transmission.

Coilers are used to coil the metal sheets, while uncoilers uncoil and feed the metal sheets into the downstream process. Helical and bevel gearboxes are used to transmit power as well as motion. Helical gearboxes are used to transmit power between parallel shifts. They are preferred for smooth operations, lower noise and high power-to-weight ratios, especially for high-torque, low-speed applications. Bevel gearboxes are used for power transmission between non-parallel shafts at right angles. They enable compact design and high power density, especially when there is a space constraint.

The sizing mill improves the dimensional accuracy of the bars and is positioned between the finishing block mill and the high-speed laying head. Helical and bevel gearboxes are used to transmit power and change speed. Helical gearboxes are used for applications where parallel shafts require smoother operations, lower noise and higher load-carrying capacity. Bevel gearboxes are used for intersecting shafts, usually at right angles.

Pinion stands are mechanical gearboxes used for transmitting power and torque from a motor in rolling mills. Both, helical and bevel gearboxes transmit power and torque. Helical gearboxes are used for smooth operations and high load capacity. Bevel gearboxes on the other hand, are used to transfer torque at right angles.

Open gears are crucial for power transmission in heavy machinery for operations in mills, cranes and excavators. Gears and pinions are key in transmitting power and motion for open gear applications such as rolling mills and kiln drives. These applications require high-torque yet low speed operations.

Control Room Cooling maintains a comfortable and stable environment for equipment and operators.

Instrument air is used in crust breaking, air nozzles, and pneumatic conveying and powers pneumatic actuators, valves, and control systems in automated processing lines.

Dust collection systems intake air through a duct system with bags that catch dust, after which they get cleaned periodically by pulsing compressed air. The dust then moves into a hopper before finally getting removed.

99% pure oxygen is blown into the vessel with an oxygen lance where iron, steel scrap and flux are combined to produce liquid steel.

In the steel and aluminium sectors, compressed air is essential to Air Separation Units (ASUs), which enable the manufacture of high-purity gases like nitrogen and oxygen. This entails compressing, cleaning, and cooling ambient air to cryogenic temperatures before separating the constituents according to their respective boiling points. In these industries, compressed air is utilized for a number of purposes, such as compression, purification, and powering pneumatic machines.

Compressed air powers tools like grinders, drills, and cutters which are used in the fabrication and maintenance of steel structures.

Surface preparation involves cleaning and preparing of surfaces before processes like painting, coating, or galvanising for proper adhesion and smooth finish.

Service air powers pneumatic tools and machinery along with providing clean air for cooling and drying.

Compressed air delivers high-pressure air to facilitate combustion and enhance iron production by introducing oxygen into the furnace.