Gears | Kirloskar Pneumatic - KPCL

Sub Product Data Content (Gears)

Outer Diameter:

2500mm

Width:

500mm

Length:

1800mm

Accuracy:

DIN Class 3/4

Type:

WHY KIRLOSKAR PNEUMATIC?

Kirloskar Pneumatic has been a leading manufacturer of gears and pinions for Indian Railways for more than four decades now. These gears and pinions are produced under stringent quality standards to meet the criterion specified by RDSO and warranted for 72 months for a trouble-free performance. We have the capacity to manufacture gears up to 2500 mm diameter with an accuracy class up to DIN Class 3/4. We have an in-house heat treatment facility and a NABL accredited lab for quality control.

After the introduction of new generation train sets like the Metro Railways & Vande Bharat, our Transmission Division has associated with global OEMs for these trains for their requirements of gears and pinions. Having done so, we have greatly contributed to the ‘Make in India’ and ‘Atmanirbhar Bharat’ movement.

FEATURES

- Smoother and quieter operation than spur gears

- Generates axial thrust, requiring thrust bearings for load absorption

- Increased load-carrying capacity due to gradual tooth engagement

Double Helical Gears

- Two opposing helical teeth sets reduce axial thrust

- Higher load-carrying capacity and smoother operation

- Ideal for high-speed and heavy-load applications

- Used in marine drives, turbines, and industrial machinery

BENEFITS

- Engineered to ensure durability, precise meshing and cater to a myriad of applications across industries

- Delivers high-performance even in challenging environments

- Customised to meet specific requirements of industries

WHY KIRLOSKAR PNEUMATIC?

Kirloskar Pneumatic has been a leading manufacturer of gears and pinions for Indian Railways for more than four decades now. These gears and pinions are produced under stringent quality standards to meet the criterion specified by RDSO and warranted for 72 months for a trouble-free performance. We have the capacity to manufacture gears up to 2500 mm diameter with an accuracy class up to DIN Class 3/4. We have an in-house heat treatment facility and a NABL accredited lab for quality control.

After the introduction of new generation train sets like the Metro Railways & Vande Bharat, our Transmission Division has associated with global OEMs for these trains for their requirements of gears and pinions. Having done so, we have greatly contributed to the ‘Make in India’ and ‘Atmanirbhar Bharat’ movement.

BENEFITS

- Engineered to ensure durability, precise meshing and cater to a myriad of applications across industries

- Delivers high-performance even in challenging environments

- Customised to meet specific requirements of industries

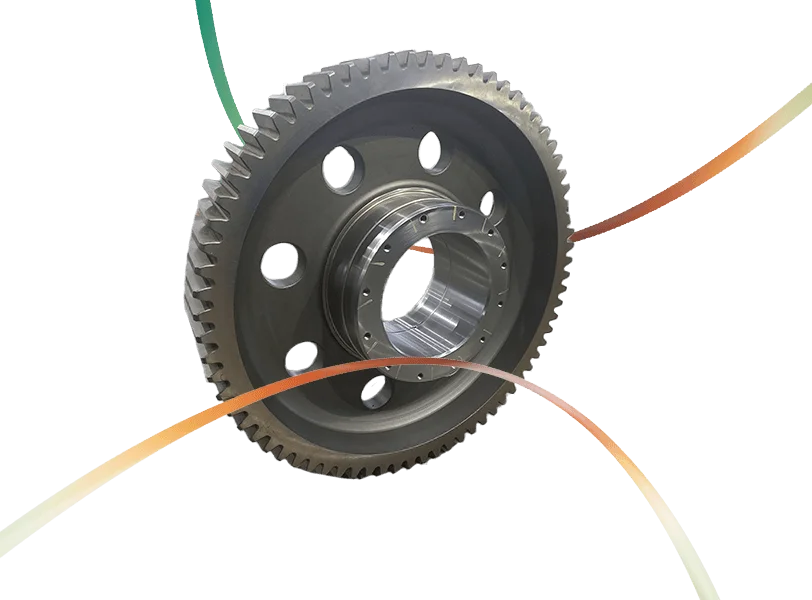

WHY KIRLOSKAR PNEUMATIC?

Kirloskar Pneumatic has been a leading manufacturer of gears and pinions for Indian Railways for more than four decades now. These gears and pinions are produced under stringent quality standards to meet the criterion specified by RDSO and warranted for 72 months for a trouble-free performance. We have the capacity to manufacture gears up to 2500 mm diameter with an accuracy class up to DIN Class 3/4. We have an in-house heat treatment facility and a NABL accredited lab for quality control.

After the introduction of new generation train sets like the Metro Railways & Vande Bharat, our Transmission Division has associated with global OEMs for these trains for their requirements of gears and pinions. Having done so, we have greatly contributed to the ‘Make in India’ and ‘Atmanirbhar Bharat’ movement.

FEATURES

- External gear that meshes with planet gears in a planetary system

- Provides a compact and high-torque transmission

- Used in automatic transmissions, wind turbines, and robotics

- Increases efficiency due to uniform load distribution

BENEFITS

- Engineered to ensure durability, precise meshing and cater to a myriad of applications across industries

- Delivers high-performance even in challenging environments

- Customised to meet specific requirements of industries

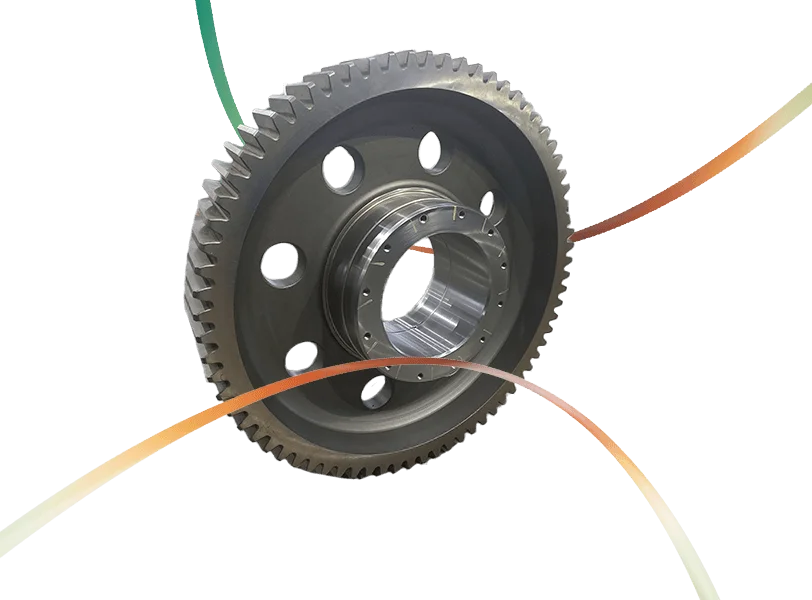

WHY KIRLOSKAR PNEUMATIC?

Kirloskar Pneumatic has been a leading manufacturer of gears and pinions for Indian Railways for more than four decades now. These gears and pinions are produced under stringent quality standards to meet the criterion specified by RDSO and warranted for 72 months for a trouble-free performance. We have the capacity to manufacture gears up to 2500 mm diameter with an accuracy class up to DIN Class 3/4. We have an in-house heat treatment facility and a NABL accredited lab for quality control.

After the introduction of new generation train sets like the Metro Railways & Vande Bharat, our Transmission Division has associated with global OEMs for these trains for their requirements of gears and pinions. Having done so, we have greatly contributed to the ‘Make in India’ and ‘Atmanirbhar Bharat’ movement.

FEATURES

- Rotates around a central sun gear and inside a ring gear

- Distributes load across multiple gears, enhancing durability

- Contributes to high torque density and efficiency

- Used in automotive transmissions and aerospace applications

BENEFITS

- Engineered to ensure durability, precise meshing and cater to a myriad of applications across industries

- Delivers high-performance even in challenging environments

- Customised to meet specific requirements of industries

WHY KIRLOSKAR PNEUMATIC?

Kirloskar Pneumatic has been a leading manufacturer of gears and pinions for Indian Railways for more than four decades now. These gears and pinions are produced under stringent quality standards to meet the criterion specified by RDSO and warranted for 72 months for a trouble-free performance. We have the capacity to manufacture gears up to 2500 mm diameter with an accuracy class up to DIN Class 3/4. We have an in-house heat treatment facility and a NABL accredited lab for quality control.

After the introduction of new generation train sets like the Metro Railways & Vande Bharat, our Transmission Division has associated with global OEMs for these trains for their requirements of gears and pinions. Having done so, we have greatly contributed to the ‘Make in India’ and ‘Atmanirbhar Bharat’ movement.

FEATURES

- Central gear in a planetary gear system

- Engages with planet gears to transmit motion

- Handles high torque and speed variations

- Used in gearboxes for automotive, industrial, and aerospace sectors

BENEFITS

- Engineered to ensure durability, precise meshing and cater to a myriad of applications across industries

- Delivers high-performance even in challenging environments

- Customised to meet specific requirements of industries

WHY KIRLOSKAR PNEUMATIC?

Kirloskar Pneumatic has been a leading manufacturer of gears and pinions for Indian Railways for more than four decades now. These gears and pinions are produced under stringent quality standards to meet the criterion specified by RDSO and warranted for 72 months for a trouble-free performance. We have the capacity to manufacture gears up to 2500 mm diameter with an accuracy class up to DIN Class 3/4. We have an in-house heat treatment facility and a NABL accredited lab for quality control.

After the introduction of new generation train sets like the Metro Railways & Vande Bharat, our Transmission Division has associated with global OEMs for these trains for their requirements of gears and pinions. Having done so, we have greatly contributed to the ‘Make in India’ and ‘Atmanirbhar Bharat’ movement.

FEATURES

- Small gear with a tapered shaft for secure mounting

- Provides enhanced alignment and reduced backlash

- Often used in heavy-duty machinery and transmission systems

- Helps in power transmission with high precision

BENEFITS

- Engineered to ensure durability, precise meshing and cater to a myriad of applications across industries

- Delivers high-performance even in challenging environments

- Customised to meet specific requirements of industries

WHY KIRLOSKAR PNEUMATIC?

Kirloskar Pneumatic has been a leading manufacturer of gears and pinions for Indian Railways for more than four decades now. These gears and pinions are produced under stringent quality standards to meet the criterion specified by RDSO and warranted for 72 months for a trouble-free performance. We have the capacity to manufacture gears up to 2500 mm diameter with an accuracy class up to DIN Class 3/4. We have an in-house heat treatment facility and a NABL accredited lab for quality control.

After the introduction of new generation train sets like the Metro Railways & Vande Bharat, our Transmission Division has associated with global OEMs for these trains for their requirements of gears and pinions. Having done so, we have greatly contributed to the ‘Make in India’ and ‘Atmanirbhar Bharat’ movement.

FEATURES

- Pinions with a central bore for shaft mounting

- Available with keyways, splines, or press-fit options

- Used in gear motors, conveyors, and drive systems

- Allows easy replacement and installation in various configurations

BENEFITS

- Engineered to ensure durability, precise meshing and cater to a myriad of applications across industries

- Delivers high-performance even in challenging environments

- Customised to meet specific requirements of industries