Diaphragm Compressors - KPCL

Sub Product Data Content (Diaphragm Compressors)

Capacity:

15.504 - 1000 kg/day

Pressure:

Up to 1034 bar

Noise Level:

< 85 dBA at 1m

Type:

Why Kirloskar Pneumatic?

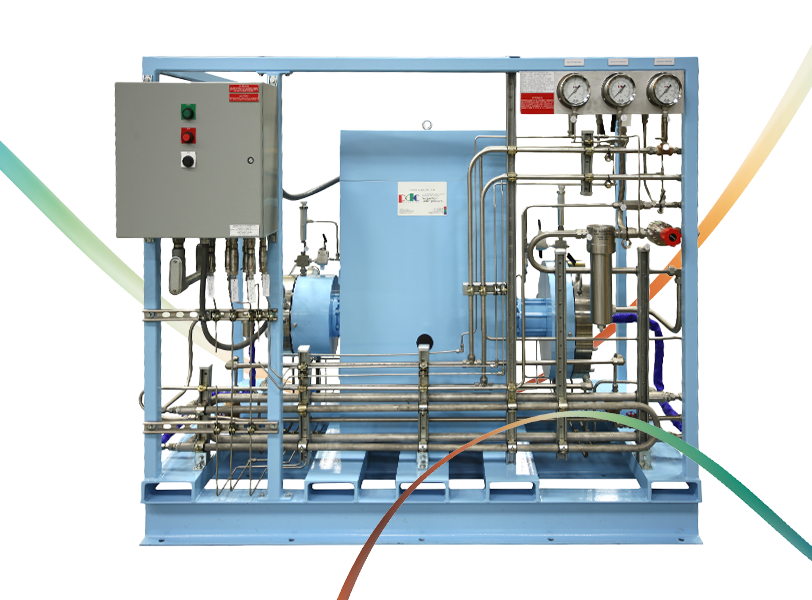

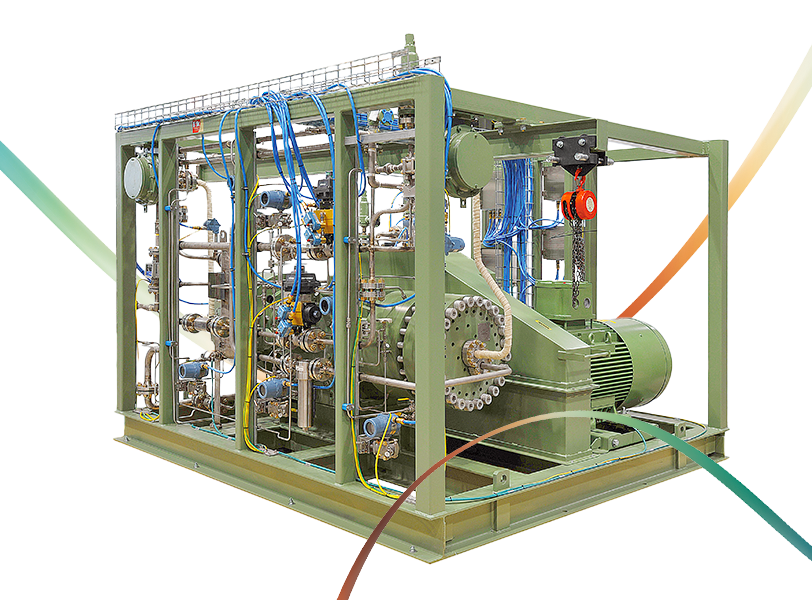

Our hydrogen diaphragm compressors set the bar for high-pressure, high-purity hydrogen applications. From renewable hydrogen generation to vehicle refuelling, these compressors deliver unmatched performance. They are built in a duplex or horizontally opposed configuration for balanced motion. With their diaphragm design, they ensure complete isolation between gas and oil, making them the go-to choice for safe, oil-free, and contamination-free compression. Valued for their reliability and efficiency, they are designed to meet the strict demands of cutting-edge hydrogen systems.

Features

- Proven PDC triple-diaphragm construction with leak detection system

- ISO 9001:2015 compliant

- Low vibration and high mechanical reliability

- Energy-efficient, compact footprint

- Easy installation and automated startup/shutdown

Benefits

- Leak-free performance and contamination prevention

- 10,000 – 40,000 hours between maintenance cycles

- Factory performance run test (8 hours pre-dispatch)

- Corrosion-resistant process parts

- Compact design for high pressure applications

- Global OEM parts availability

- Factory-trained technicians for installation & commissioning

Why Kirloskar Pneumatic?

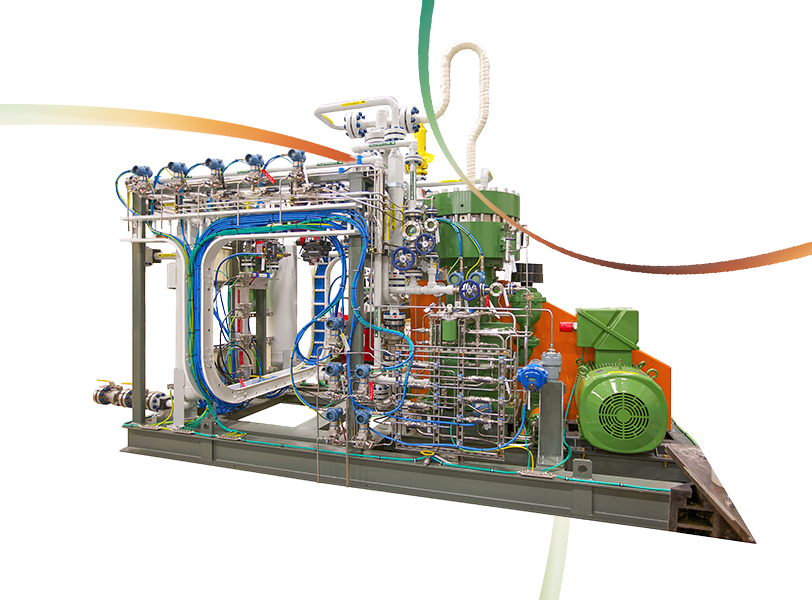

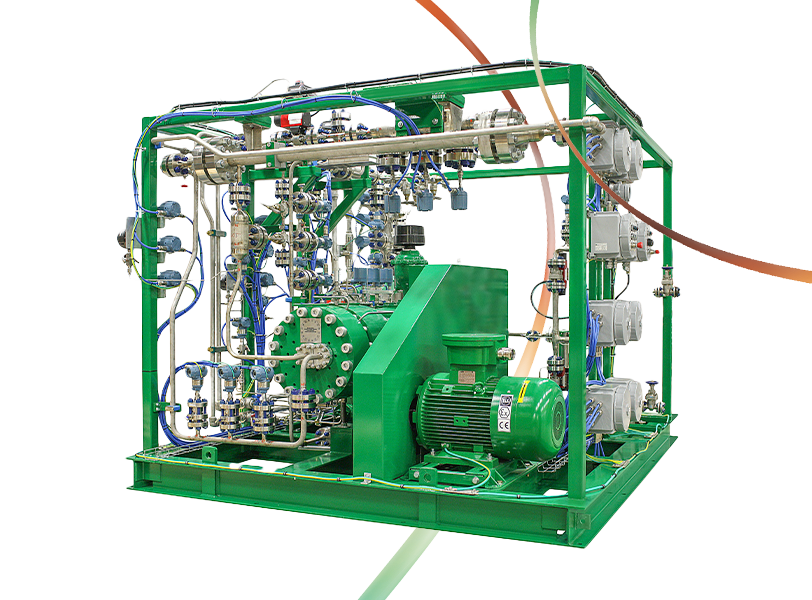

Built for the most demanding applications, our industrial diaphragm compressors offer consistent, high-performance compression where reliability and purity are critical. Whether handling gases in sensitive applications or in harsh operational settings, these compressors are built to ensure oil-free and contamination-free results. They are available in single-stage, two-stage, or duplex configurations. Their robust design makes them a trusted choice across various industries, ensuring long-lasting, safe operation in high-pressure conditions.

Features

- Proven PDC triple-diaphragm construction with leak detection system

- ISO 9001:2015 compliant

- Low vibration and high mechanical reliability

- Energy-efficient, compact footprint

- Easy installation and automated startup/shutdown

Benefits

- Leak-free performance and contamination prevention

- 10,000 – 40,000 hours between maintenance cycles

- Factory performance run test (8 hours pre-dispatch)

- Corrosion-resistant process parts

- Compact design for high pressure applications

- Global OEM parts availability

- Factory-trained technicians for installation & commissioning