Automotive Engineering | Kirloskar Pneumatic - KPCL

Automotive Engineering

Driving the future through accelerated efficiency

Driving the future of mobility, automotive engineering leads the path of innovation with improved vehicle manufacturing and new technology.

At Kirloskar Pneumatic, our advanced solutions power every stage of this evolving innovation, from engine construction to assembly, to painting and cleaning. As vehicles become lighter and stronger with advanced materials, pneumatic tools powered by our Air Compressors ensure precision in crafting components and powering essential machinery.

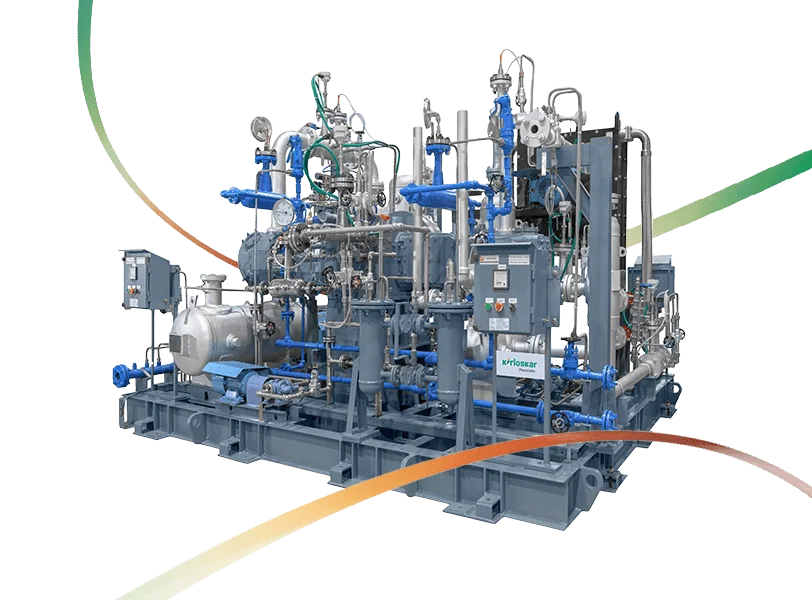

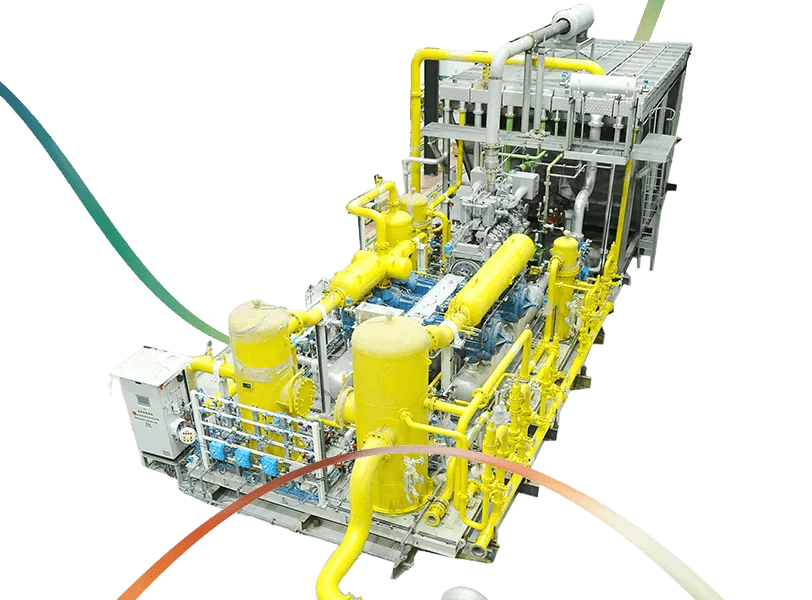

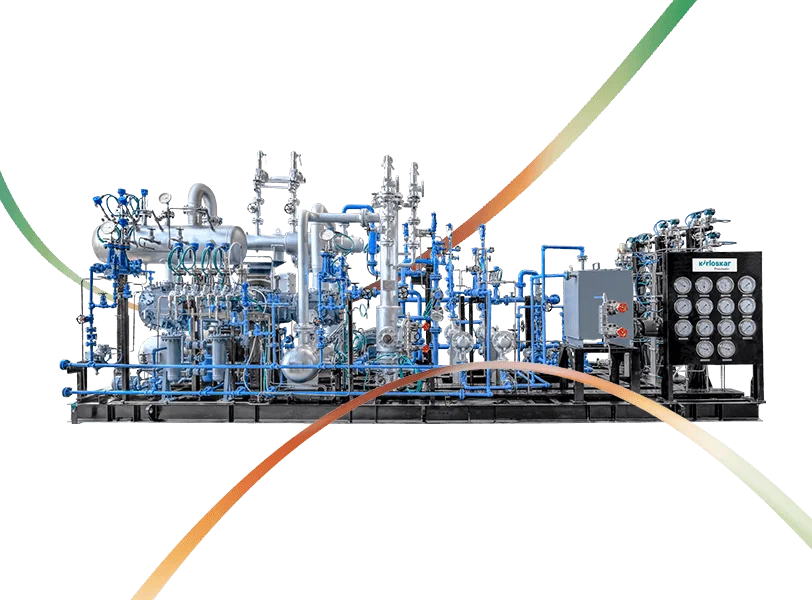

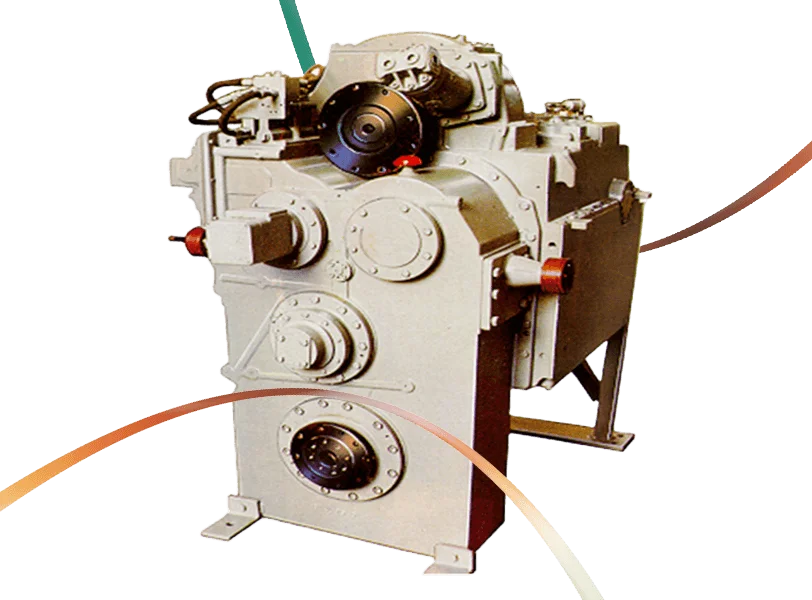

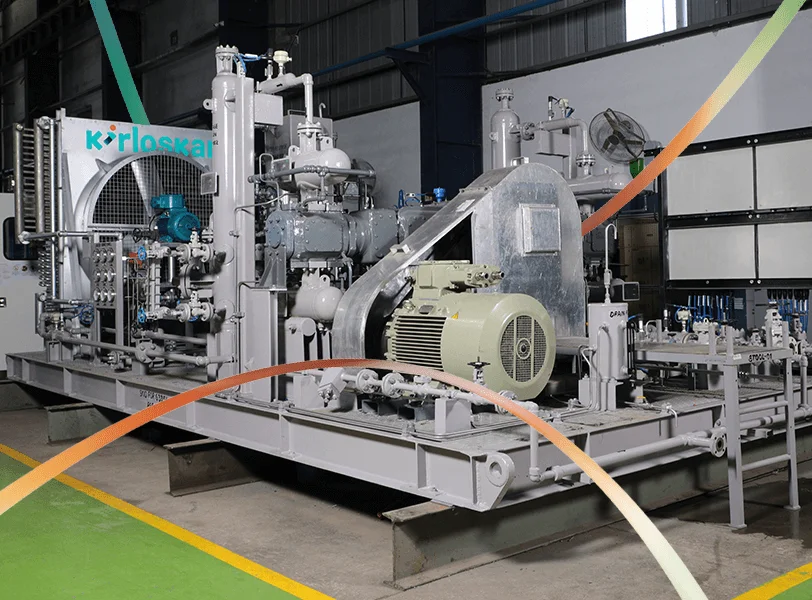

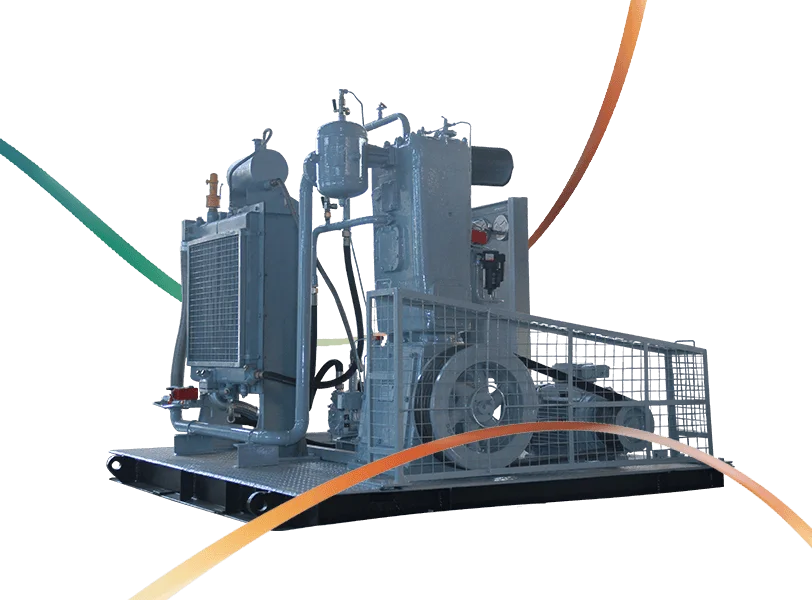

Our Air Compressor Division supports every critical function on the production floor with reliable solutions, ranging from oil-injected electric screw compressors to centrifugal and reciprocating gas compressors, including vertical and horizontal balanced opposed configurations, ensuring uninterrupted performance and energy efficiency.

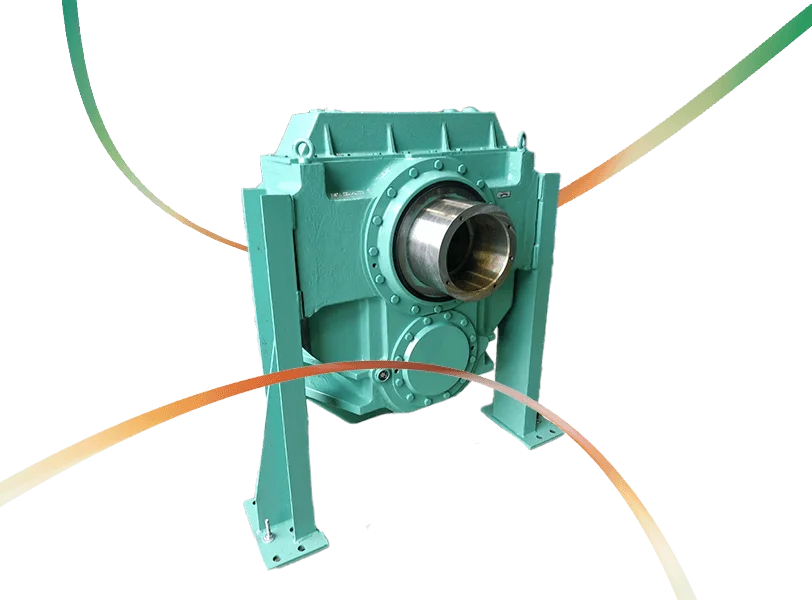

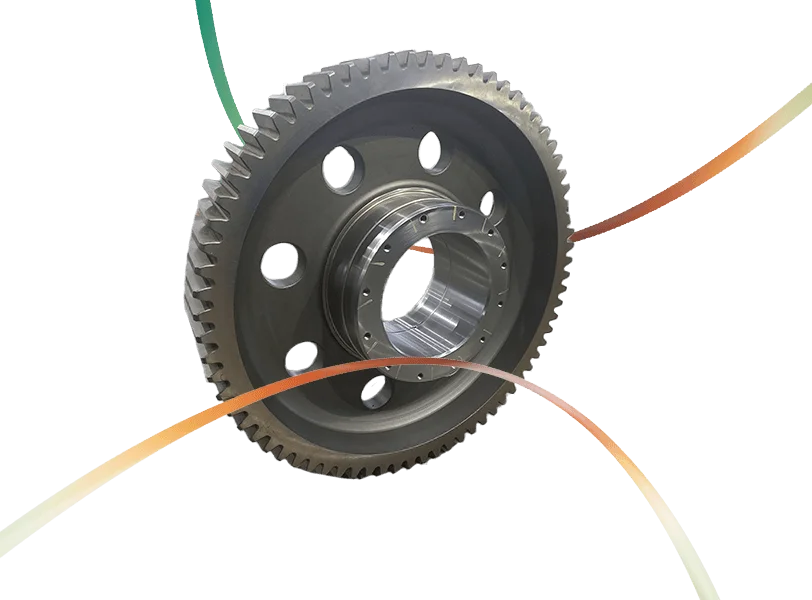

Complementing this is our Transmission portfolio, where high-precision gears and pinions enhance durability and power transmission in automotive systems, meeting the demands of modern mobility. Our solutions do more than keep the wheels turning. We engineer the momentum behind tomorrow’s transportation.

AUTOMOTIVE ENGINEERING

Driving the future through accelerated efficiency

Driving the future of mobility, automotive engineering leads the path of innovation with improved vehicle manufacturing and new technology.

At Kirloskar Pneumatic, our advanced solutions power every stage of this evolving innovation, from engine construction to assembly, to painting and cleaning. As vehicles become lighter and stronger with advanced materials, pneumatic tools powered by our Air Compressors ensure precision in crafting components and powering essential machinery.

Our Air Compressor Division supports every critical function on the production floor with reliable solutions, ranging from oil-injected electric screw compressors to centrifugal and reciprocating gas compressors, including vertical and horizontal balanced opposed configurations, ensuring uninterrupted performance and energy efficiency.

Complementing this is our Transmission portfolio, where high-precision gears and pinions enhance durability and power transmission in automotive systems, meeting the demands of modern mobility. Our solutions do more than keep the wheels turning. We engineer the momentum behind tomorrow’s transportation.

Asset Publisher

Choose Applications

Air Conditioning/Equipment Cooling | Control Room Cooling...

Wort Cooling | Air Conditioning/Equipment Cooling | Control Room Cooling...

Reactor Cooling | Coffee Extract Cooling | Recycled Bottle Cooling...

Pulp Cooling in Pasteurization | Cooling in Pasteurisation...

Wort Cooling | Air Conditioning/Equipment Cooling | Control Room Cooling...

Flare Gas Recovery | LNG | LPG | BOG | GTL | Aromatics...

Flare Gas Recovery | Process Control and Instrumentation | LNG | LPG | BOG...

Pharmaceutical Storage | Freeze Drying (Lyophilisation)...

Traction Motors

Drilling Operations | Pipeline Maintenance and Testing...

Drilling Operations | Pipeline Maintenance and Testing...

Sandblasting | Jack hammer | Excavation | DTH Drilling | Tunnelling...

Flare Gas Recovery | Fuel Gas Booster | Gas Gathering | Gas Booster...

Drilling Operations | Pipeline Maintenance and Testing...

Wort Cooling | Air Conditioning/Equipment Cooling | Control Room Cooling...

(Comfort Cooling) Air Conditioning | Air Conditioning/Equipment Cooling

Blowers and Fans | Pinion Stand | Roughing Mill | Ladle Tilters | Sizing Mill...

Speciality pumps and compressor drives | Co-generations turbines...

Steel Furnace Tilter | Turbine | Sugar Mill Drive

Sandblasting | Jack hammer | Excavation | DTH Drilling | Tunnelling...

Carbon Dioxide Liquefaction | Chemical Reactors Cooling...

Pharmaceutical Storage | Freeze Drying (Lyophilisation)...

Pharmaceutical Storage | Freeze Drying (Lyophilisation)...

Pharmaceutical Storage | Freeze Drying (Lyophilisation)...

Bulker and train unloading | Silo fluidization | Combustion air...

Chilled Water Plants | Refrigeration Plants

HVAC Plants

Chilled Water Plants | Refrigeration Plants | HVAC Plants

Chilled Water Plants | Refrigeration Plants | HVAC Plants

Chilled Water Plants | Refrigeration Plants | HVAC Plants

Wind Turbine

Shunting Locomotives Drives

Open Gears

Flare Gas Recovery | Fuel Gas Booster | Gas Gathering | Vapor Recovery...

Gas Grid Injection | Cascade Filling

NGV Filling

NGV Filling

Sandblasting | Jack hammer | Excavation | DTH Drilling | Tunnelling...

Drilling Operations | Pipeline Maintenance and Testing...

Flare Gas Recovery | LNG | LPG | BOG | GTL | Aromatics...

Asset Publisher

No results found

Gears, particularly pinion gears, are essential components in traction motors used in various industries, especially in transportation, to transmit power and control the speed of rotating axles. They connect the motor shaft to the axle, allowing the motor's rotational motion to drive the wheels. Gears and pinions work together to make this possible. They transmit torque and power from the engine or the motor to the wheels. This is crucial to ensure efficient power delivery and speed control.

Air compressors stamp and cut materials into rough shapes as part of the moulding process to meet the requirements of the products.

Compressed air shapes materials in blow moulding, applies pressure in thermoforming and powers pneumatic actuators to facilitate part ejection, cooling and cleaning. Furthermore, it also aids in leak testing and equipment maintenance.

Compressed air powers robots and light-weight pneumatic tools for efficient and cost-effective car assembly.

The air compressor at gas stations is used to fill air in tyres, which helps maintain the safety and reliability of your automobile.

Compressed air plays a crucial role in operating assembly lines and pneumatic tools in the automobile industry. It powers various machines and tools used in the manufacturing process, from stamping and forming components to lifting, positioning, and fastening parts.

Compressed air is vital for surface preparation as it helps clean car bodies by removing dust and debris before painting.

Compressed air helps in the painting and coating of automobiles by powering spray guns with Silicone-free air for fine, even coating and ensuring safe paint pump operation in highly volatile environments.