Power Generation | Kirloskar Pneumatic - KPCL

POWER GENERATION

Harnessing energy to power the future

Fueling nations and empowering industries, power generation lies at the heart of global progress, spanning thermal, hydro, and renewable sources. Each form of energy demands precision, reliability, and robust engineering to operate at peak efficiency.

At Kirloskar Pneumatic, we support the power generation sector with a comprehensive range of solutions that enable efficient operations across diverse environments.

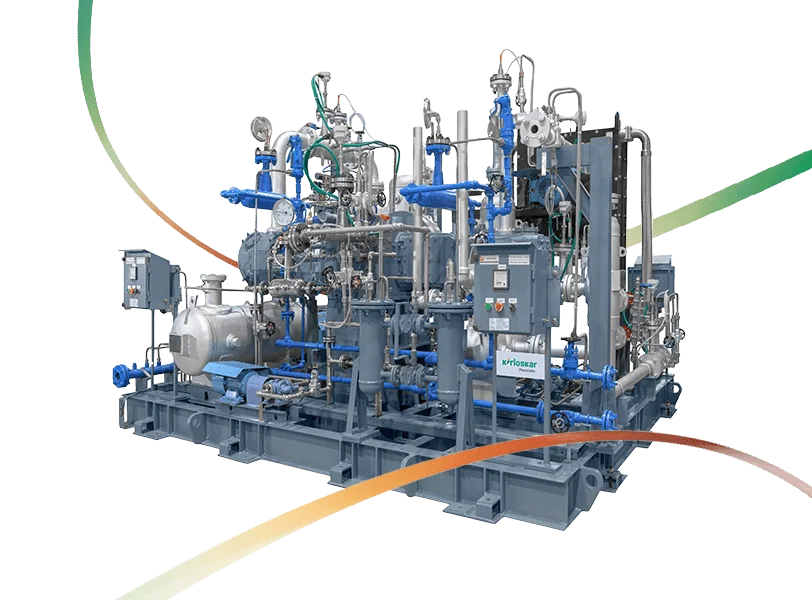

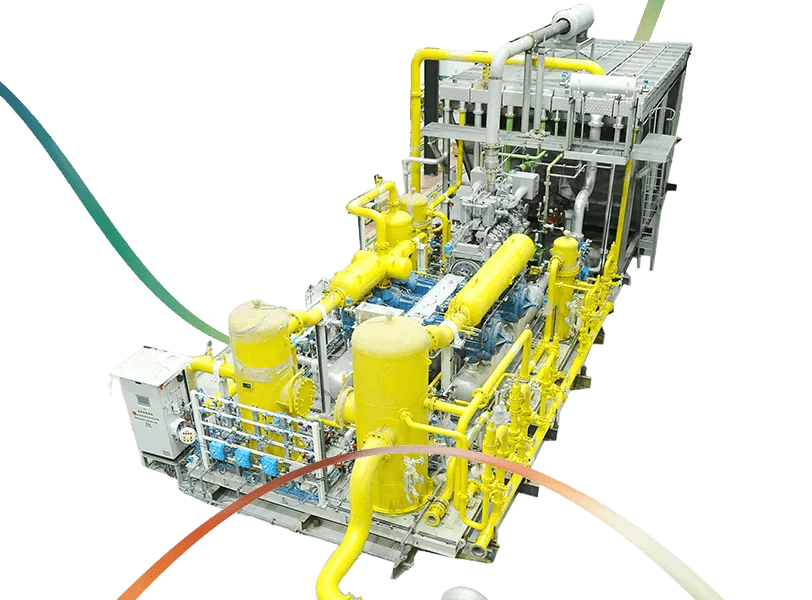

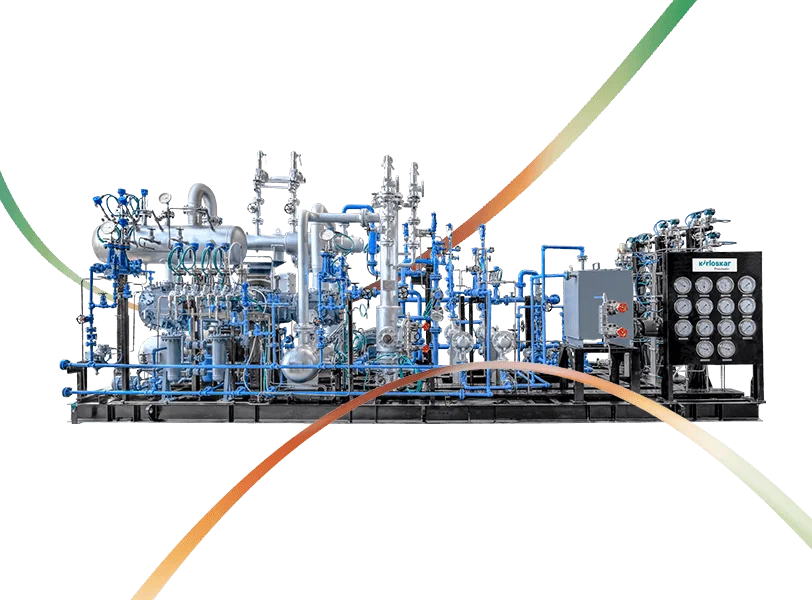

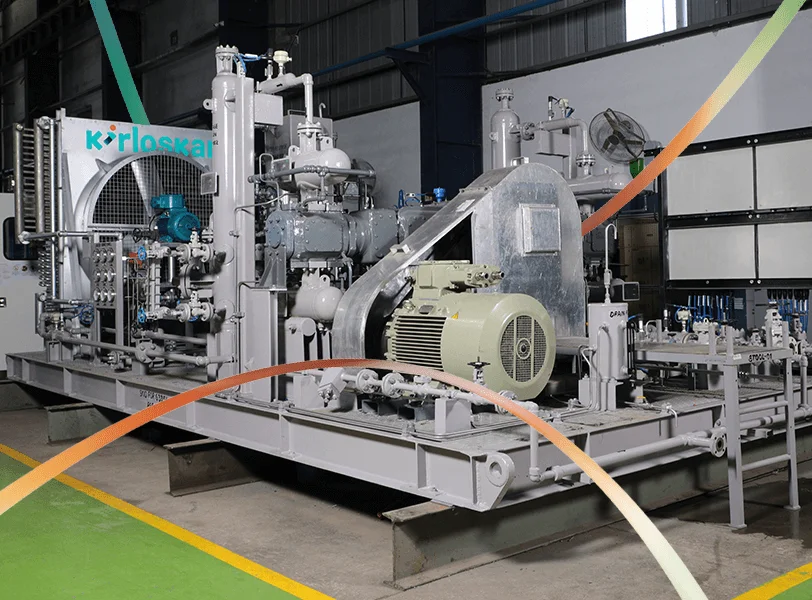

Our Air Compressor Division plays a critical role in supporting power plants, whether it’s coal drying, ash handling, combustion air supply in thermal plants, valve automation and turbine cooling in hydro power, or cleaning systems in renewables. With centrifugal air compressors, vertical and horizontal reciprocating models, and gas compressors, we deliver consistent performance in even the most demanding applications.

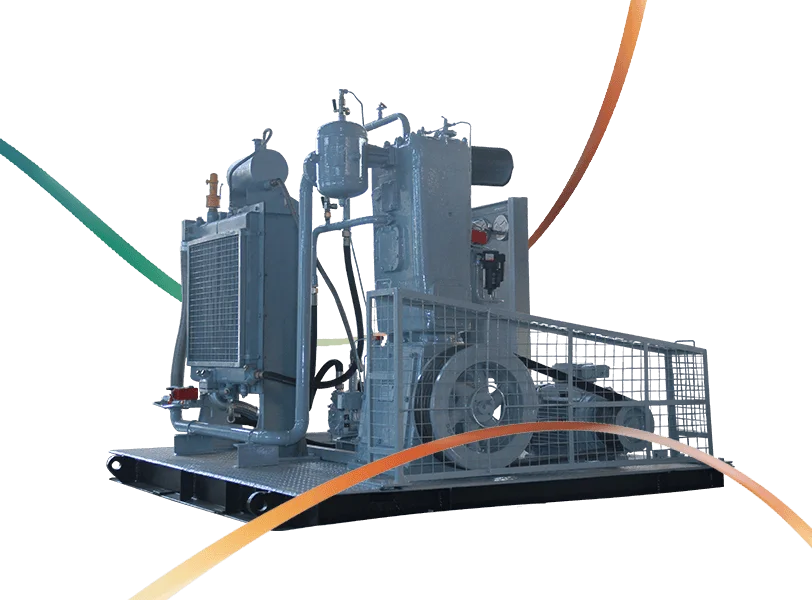

Our Air Conditioning and Refrigeration systems that include steam-driven, hot water-driven, direct-fired, and exhaust-driven double-effect vapour absorption chillers to help maintain stable temperatures and efficient heat recovery in auxiliary systems, contributing to the overall operational efficiency of power plants.

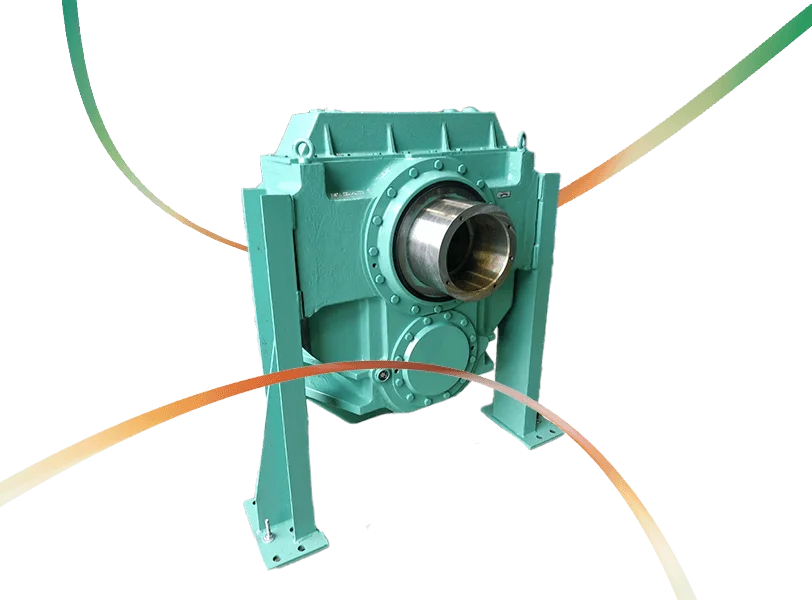

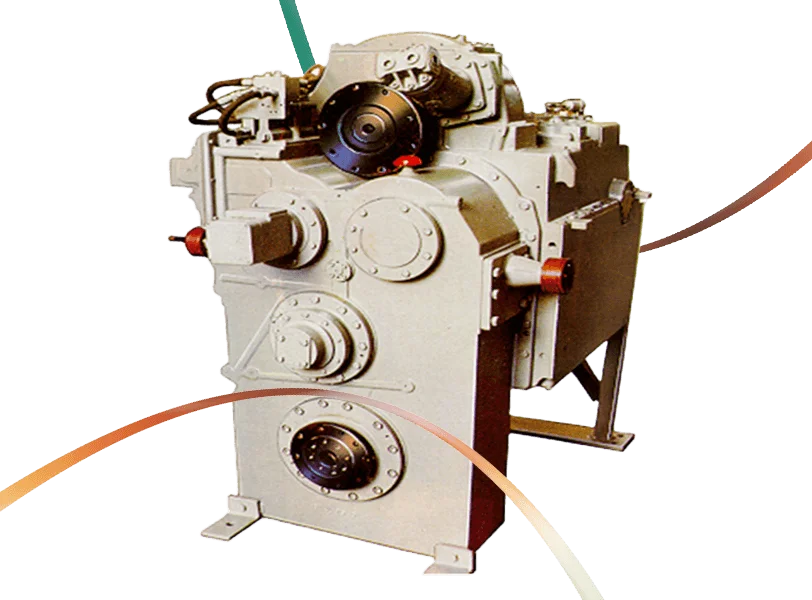

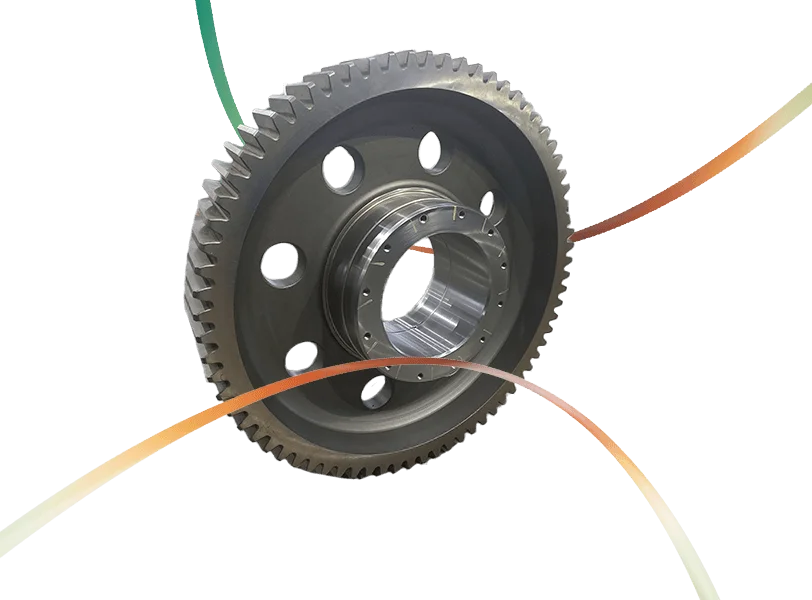

In the field of Transmission, our high-speed gearboxes, hydro turbine gearboxes, windmill gearboxes, planetary drives, and railway transmissions ensure optimal power transfer and performance be it for driving turbines or supporting renewable infrastructure.

At Kirloskar Pneumatic, we are building the future of energy with engineered resilience, sustainable performance, and unwavering reliability.

Power Generation

Harnessing energy to power the future

Fueling nations and empowering industries, power generation lies at the heart of global progress, spanning thermal, hydro, and renewable sources. Each form of energy demands precision, reliability, and robust engineering to operate at peak efficiency.

At Kirloskar Pneumatic, we support the power generation sector with a comprehensive range of solutions that enable efficient operations across diverse environments.

Our Air Compressor Division plays a critical role in supporting power plants, whether it’s coal drying, ash handling, combustion air supply in thermal plants, valve automation and turbine cooling in hydro power, or cleaning systems in renewables. With centrifugal air compressors, vertical and horizontal reciprocating models, and gas compressors, we deliver consistent performance in even the most demanding applications.

Our Air Conditioning and Refrigeration systems that include steam-driven, hot water-driven, direct-fired, and exhaust-driven double-effect vapour absorption chillers to help maintain stable temperatures and efficient heat recovery in auxiliary systems, contributing to the overall operational efficiency of power plants.

In the field of Transmission, our high-speed gearboxes, hydro turbine gearboxes, windmill gearboxes, planetary drives, and railway transmissions ensure optimal power transfer and performance be it for driving turbines or supporting renewable infrastructure.

At Kirloskar Pneumatic, we are building the future of energy with engineered resilience, sustainable performance, and unwavering reliability.