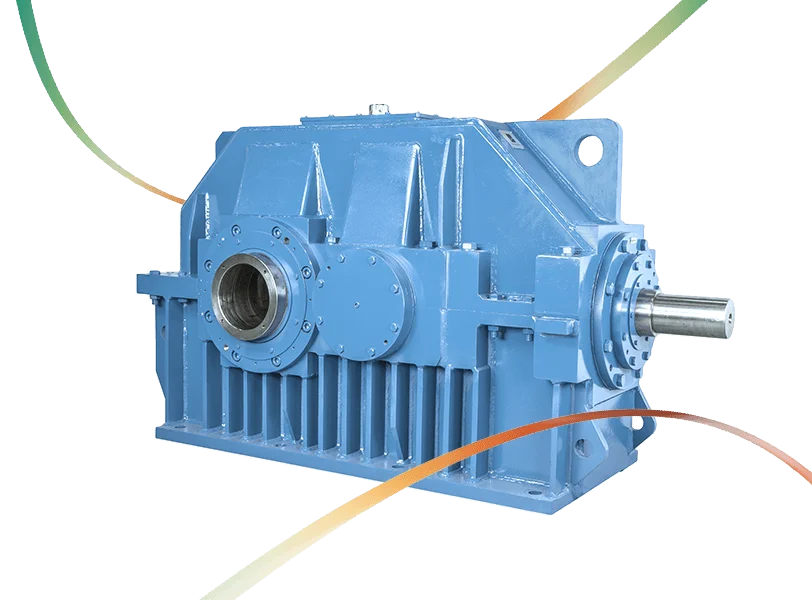

Helical Bevel Gearboxes | Kirloskar Pneumatic - KPCL

Sub Product Data Content (Helical & Bevel Gearboxes)

Torque:

Up to 6000 kNm

Module:

0.5 to 25

Accuracy:

DIN Class 4/5

Type:

WHY KIRLOSKAR PNEUMATIC?

We use cutting-edge technology and infrastructure to deliver top-quality Helical and Bevel gearboxes. Our Transmission Division consists of state-of-the-art facilities, including a dedicated foundry, CNC turning and machining centres, advanced Gear Teeth grinding and cutting equipment, in-house heat treatment, and precision gear grinding. We also utilize gear profile inspection testers, 3-axis coordinate measuring machines, and non-destructive testing methods like ultrasonic testing and Megnaflux machine (crack detection) to ensure the highest standards of manufacturing and quality control.

We are committed to excellence, holding ISO 9001:2015, ISO 45001:2018, and ISO 14001:2015 certifications for quality, safety, and environmental management. Our products are also certified by leading national and international agencies such as the Indian Register of Shipping, RITES, and the Marine Mercantile Department (MMD). With our advanced facilities, rigorous quality assurance, and certification for excellence, Kirloskar Pneumatic is the ideal choice for reliable and high-performance helical and bevel gearboxes.

FEATURES

- Case-hardened, profile-ground helical gears for quiet operation and high torque

- Shaft sized per DIN 743, designed for standard and custom load conditions

- Sump lubrication with optional pumps, with mineral or synthetic oils

- Fabricated steel casings with FEA design

- Bearings optimised for L10 life, with taper roller for small units, spherical for larger

- Radial lip seals with labyrinth design for leak prevention

- Custom accessories like holdbacks, base plates, and motor mounts

- We use only globally reputed made bearings

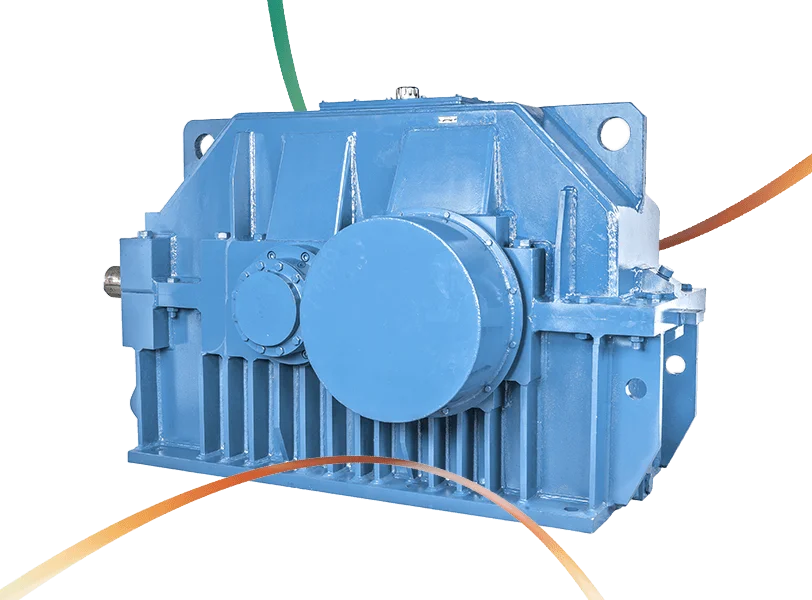

WHY KIRLOSKAR PNEUMATIC?

We use cutting-edge technology and infrastructure to deliver top-quality Helical and Bevel gearboxes. Our Transmission Division consists of state-of-the-art facilities, including a dedicated foundry, CNC turning and machining centres, advanced Gear Teeth grinding and cutting equipment, in-house heat treatment, and precision gear grinding. We also utilize gear profile inspection testers, 3-axis coordinate measuring machines, and non-destructive testing methods like ultrasonic testing and Megnaflux machine (crack detection) to ensure the highest standards of manufacturing and quality control.

We are committed to excellence, holding ISO 9001:2015, ISO 45001:2018, and ISO 14001:2015 certifications for quality, safety, and environmental management. Our products are also certified by leading national and international agencies such as the Indian Register of Shipping, RITES, and the Marine Mercantile Department (MMD). With our advanced facilities, rigorous quality assurance, and certification for excellence, Kirloskar Pneumatic is the ideal choice for reliable and high-performance helical and bevel gearboxes.

FEATURES

- Case-hardened, profile-ground helical gears for quiet operation and high torque

- Shaft sized per DIN 743, designed for standard and custom load conditions

- Sump lubrication with optional pumps, with mineral or synthetic oils

- Fabricated steel casings with FEA design

- Bearings optimised for L10 life, with taper roller for small units, spherical for larger

- Radial lip seals with labyrinth design for leak prevention

- Custom accessories like holdbacks, base plates, and motor mounts

- We use only globally reputed made bearings

WHY KIRLOSKAR PNEUMATIC?

We use cutting-edge technology and infrastructure to deliver top-quality Helical and Bevel gearboxes. Our Transmission Division consists of state-of-the-art facilities, including a dedicated foundry, CNC turning and machining centres, advanced Gear Teeth grinding and cutting equipment, in-house heat treatment, and precision gear grinding. We also utilize gear profile inspection testers, 3-axis coordinate measuring machines, and non-destructive testing methods like ultrasonic testing and Megnaflux machine (crack detection) to ensure the highest standards of manufacturing and quality control.

We are committed to excellence, holding ISO 9001:2015, ISO 45001:2018, and ISO 14001:2015 certifications for quality, safety, and environmental management. Our products are also certified by leading national and international agencies such as the Indian Register of Shipping, RITES, and the Marine Mercantile Department (MMD). With our advanced facilities, rigorous quality assurance, and certification for excellence, Kirloskar Pneumatic is the ideal choice for reliable and high-performance helical and bevel gearboxes.

FEATURES

- Case-hardened, profile-ground helical gears for quiet operation and high torque

- Shaft sized per DIN 743, designed for standard and custom load conditions

- Sump lubrication with optional pumps, with mineral or synthetic oils

- Fabricated steel casings with FEA design

- Bearings optimised for L10 life, with taper roller for small units, spherical for larger

- Radial lip seals with labyrinth design for leak prevention

- Custom accessories like holdbacks, base plates, and motor mounts

- We use only globally reputed made bearings