Reciprocating Horizontal Balanced Opposed Air Compressor | Kirloskar Pneumatic - KPCL

Sub Product Data Content (Reciprocating Horizontal Balanced Opposed Air Compressor)

Capacity:

32 to 4200 cfm

Pressure:

1 to 400 kg/cm2 (g)

Type:

WHY KIRLOSKAR PNEUMATIC?

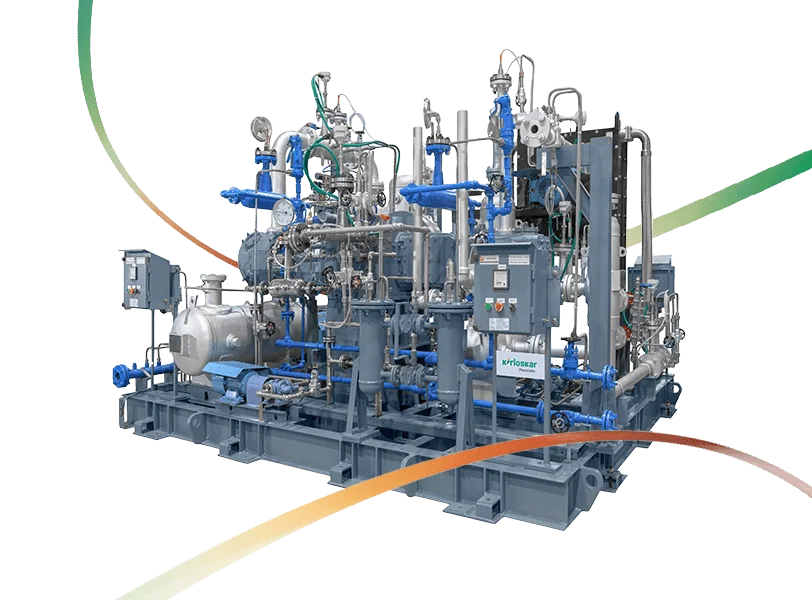

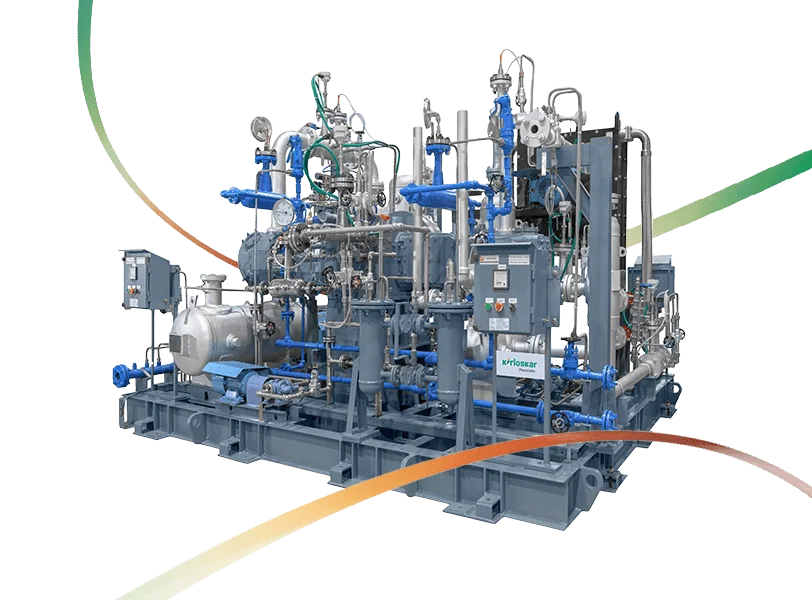

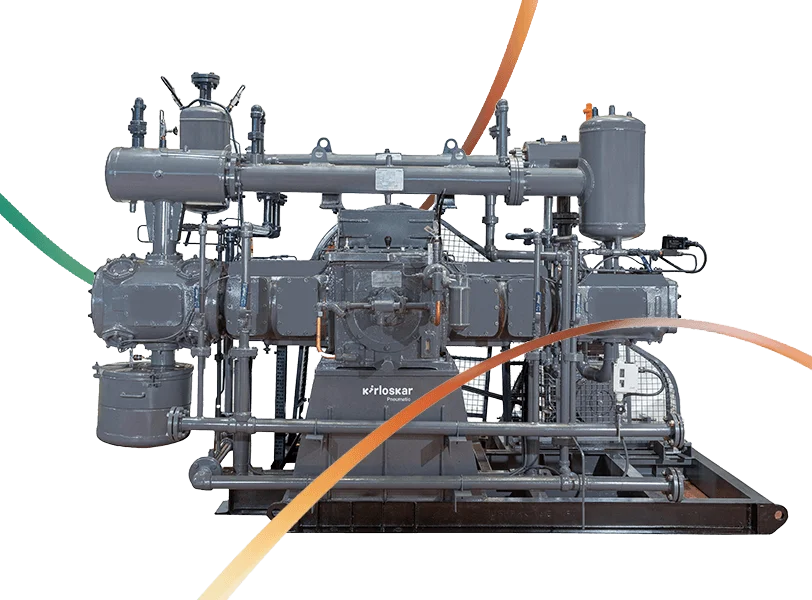

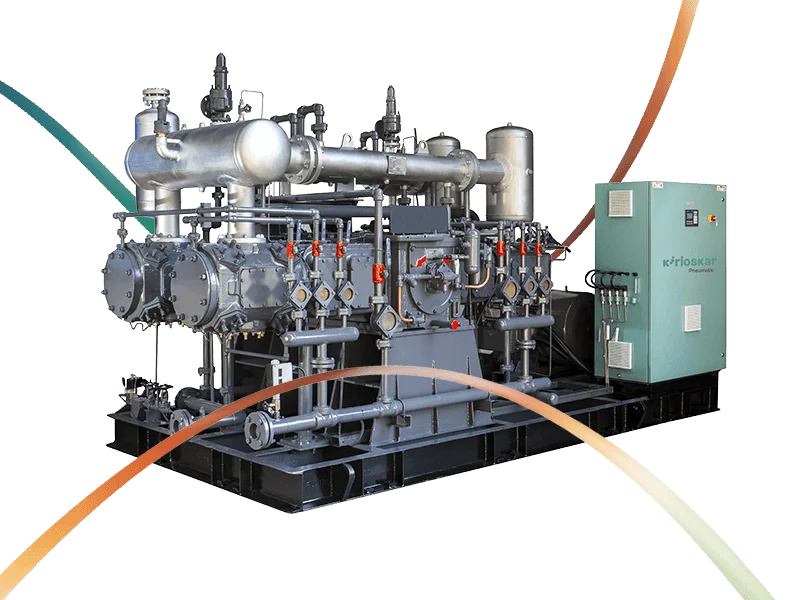

The Kirloskar Pneumatic horizontal balanced opposed air compressors are the result of extensive know-how and experience of more than six decades in design, manufacture, supply and installation of air compressors of various design, capacities and pressures for a number of applications. Due to wide modular design, our compressors can meet any combination of capacity and pressure. Our proud experience gathered over many years enables us to design and supply compressors tailored to the specific needs of our customers.

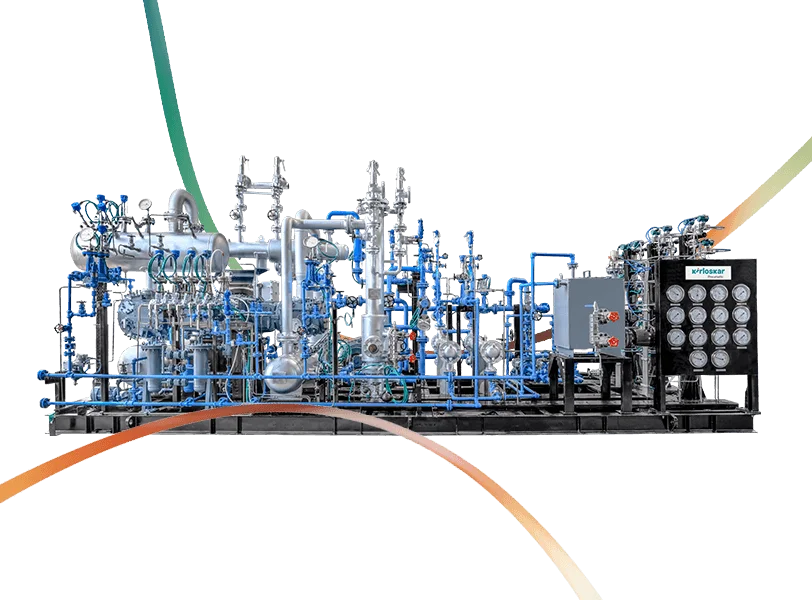

Our reciprocating air compressors provide oil-free air, courtesy an efficient crosshead housing and PTFE piston rings for extended duty cycles. Their zero-couple design for medium pressure ranges ensures low vibration, while the unique base frame requires no special foundation, resulting in smooth operation and reduced wear on moving parts. Available in both air-cooled and water-cooled versions, these compressors are customised to meet specific application requirements. High-pressure customised skid-mounted packages can also be delivered to accommodate demanding needs.

The heavy-duty cylinder and crankcase enhance strength and durability, while lightweight, self-lubricating pistons lower energy consumption and heat dissipation. We offer specifically bespoke solutions and an acoustically designed modular canopy for silent operation and effective ventilation. The smart control system features a microprocessor-controlled starter and real-time monitoring for alarms. Our compressors deliver proven heavy-duty performance, ease of maintenance, and high reliability at high temperatures and altitudes, all while being energy-efficient with lower operating costs. With capabilities of up to 6 stages and a pressure range reaching 400 Kg/cm² g, we provide comprehensive solutions on a turnkey basis, including techno-commercial consultation and on-site commissioning. Our modular design with a compact footprint and hassle-free commissioning and after-sales service across India, ensures compliance with the latest compressor standards tailored to meet specific application requirements.

FEATURES

-

Oil-Free Air: Strategically designed crosshead housing and long-distance piece with efficient oil scraper ensures separation of oil from compression chamber, along with PTFE piston rings for longer duty cycles

-

Vibration-Free Performance: Crank throws set at 180° with weights of the reciprocating parts of opposing cylinders equalised, to achieve smooth running and reduce part wear

-

Cylinder and Crankcase: Heavy duty cylinder design for maximum durability, and heavy duty crankcase with proper lubrication

-

Pistons: Lightweight and self-lubricating pistons for energy savings, with rider rings for smooth running and low heat dissipation

-

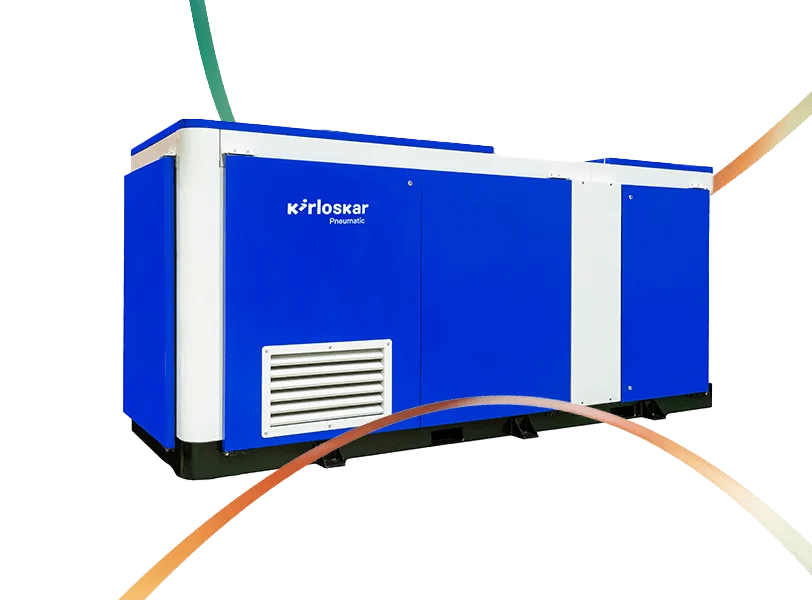

Canopy: Acoustically designed, modular metallic canopy for silent operations with easy access for maintenance

-

Smart Control and Monitoring: In-built microprocessor-controlled starter cum control panel, with Type 2 co-ordination starters for safety

BENEFITS

- Withstands high temperatures and altitudes

- High reliability certified through rigorous testing

- Energy efficient

- Low operating and lifecycle costs

- Easy to install

- Lower footprint

- Pan India hassle-free commissioning and after-sales service

WHY KIRLOSKAR PNEUMATIC?

The Kirloskar Pneumatic horizontal balanced opposed air compressors are the result of extensive know-how and experience of more than six decades in design, manufacture, supply and installation of air compressors of various design, capacities and pressures for a number of applications. Due to wide modular design, our compressors can meet any combination of capacity and pressure. Our proud experience gathered over many years enables us to design and supply compressors tailored to the specific needs of our customers.

Our reciprocating air compressors provide oil-free air, courtesy an efficient crosshead housing and PTFE piston rings for extended duty cycles. Their zero-couple design for medium pressure ranges ensures low vibration, while the unique base frame requires no special foundation, resulting in smooth operation and reduced wear on moving parts. Available in both air-cooled and water-cooled versions, these compressors are customised to meet specific application requirements. High-pressure customised skid-mounted packages can also be delivered to accommodate demanding needs.

The heavy-duty cylinder and crankcase enhance strength and durability, while lightweight, self-lubricating pistons lower energy consumption and heat dissipation. We offer specifically bespoke solutions and an acoustically designed modular canopy for silent operation and effective ventilation. The smart control system features a microprocessor-controlled starter and real-time monitoring for alarms. Our compressors deliver proven heavy-duty performance, ease of maintenance, and high reliability at high temperatures and altitudes, all while being energy-efficient with lower operating costs. With capabilities of up to 6 stages and a pressure range reaching 400 Kg/cm² g, we provide comprehensive solutions on a turnkey basis, including techno-commercial consultation and on-site commissioning. Our modular design with a compact footprint and hassle-free commissioning and after-sales service across India, ensures compliance with the latest compressor standards tailored to meet specific application requirements.

FEATURES

- Oil-Free Air: Strategically designed crosshead housing and long-distance piece with efficient oil scraper ensures separation of oil from compression chamber, along with PTFE piston rings for longer duty cycles

-

Vibration-Free Performance: Crank throws set at 180° with weights of the reciprocating parts of opposing cylinders equalised, to achieve smooth running and reduce part wear

-

Cylinder and Crankcase: Heavy duty cylinder design for maximum durability, and heavy duty crankcase with proper lubrication

-

Pistons: Lightweight and self-lubricating pistons for energy savings, with rider rings for smooth running and low heat dissipation

-

Canopy: Acoustically designed, modular metallic canopy for silent operations with easy access for maintenance

-

Smart Control and Monitoring: In-built microprocessor-controlled starter cum control panel, with Type 2 co-ordination starters for safety

BENEFITS

- Withstands high temperatures and altitudes

- High reliability certified through rigorous testing

- Energy efficient

- Low operating and lifecycle costs

- Easy to install

- Lower footprint

- Pan India hassle-free commissioning and after-sales service