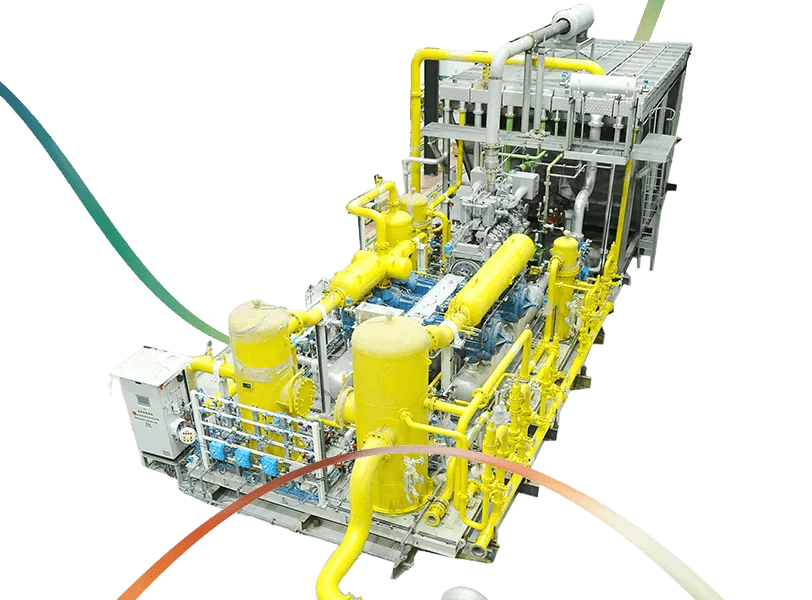

Reciprocating Gas Compressor Packages | Kirloskar Pneumatic - KPCL

Sub Product Data Content (Reciprocating Gas Compressor Packages)

Pressure Range:

1 to 580 bar

Gas Flow:

50 to 6000 CFM

Why Kirloskar Pneumatic?

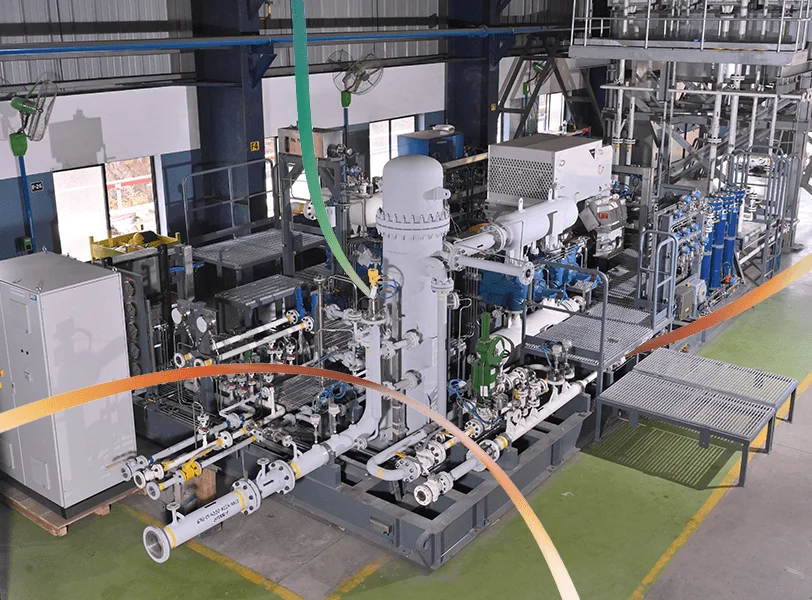

Kirloskar Pneumatic is the authorised packager for Ariel USA in India, Middle East, Southeast Asia and Africa. The compressors are ISO 13631 compliant ensuring that compressors are safe, and efficient. Our reciprocating gas compression packages are designed to deliver reliable, high-performance solutions for a wide range of industrial applications. Built for durability and efficiency, these systems ensure optimal gas compression, even in challenging conditions.

Features

- Designed for high-pressure applications.

- Durable: Made to withstand tough industrial conditions for a longer lifespan.

- Safety Certified: Complies with API 11P, ASME, and ASTM/ANSI standards.

- Optimised Performance: Engineered with advanced models for peak efficiency.

- Low Maintenance: Minimal upkeep, with higher uptime.

- High Pressure Capabilities: Capable of delivering high discharge pressures, making them suitable for applications requiring significant pressure boosts.

- Durability and Reliability: Built to withstand harsh operating conditions, including high temperatures, corrosive gases, and continuous duty cycles.

- Energy Efficiency: Optimised for energy efficiency with advanced control systems they are built to adjust operations based on load demand.

- Customised: Available in a variety of configurations to suit specific process requirements, including different power sources, materials, and cooling systems.

- Advanced Control Systems: Equipped with modern control systems for monitoring and adjusting performance in real-time, enhancing operational efficiency and safety.

Benefits

- Designed to perform reliably in harsh conditions, with attention to detail in material selection and fabrication, ensuring a long service life and safe operation.

- Adheres to API 11P, ASME, ASTM/ANSI standards, with detailed 2D/3D designs and process simulations for optimised performance.

- Low maintenance requirements with higher package uptime and advanced IoT-enabled systems for real-time monitoring and efficiency.

- A proven track record demonstrates the robust performance and widespread acceptance.