Oil & Gas | Kirloskar Pneumatic - KPCL

Oil & Gas

Transforming resources into opportunity

Fuelling progress, driving economies, and powering the world, the oil and gas industry remains the backbone of global growth and innovation.

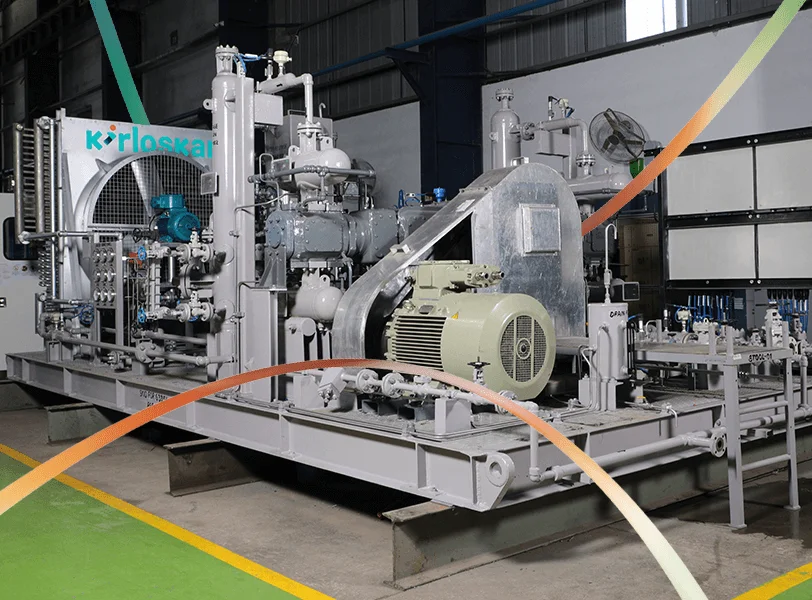

We, at Kirloskar Pneumatic, strengthen this foundation with cutting-edge solutions for pipeline transportation, petroleum refining, and petrochemical synthesis. Our expertise lies in designing and manufacturing refrigeration packages for various applications in the sector, along with gas compressors tailored for the CNG industry.

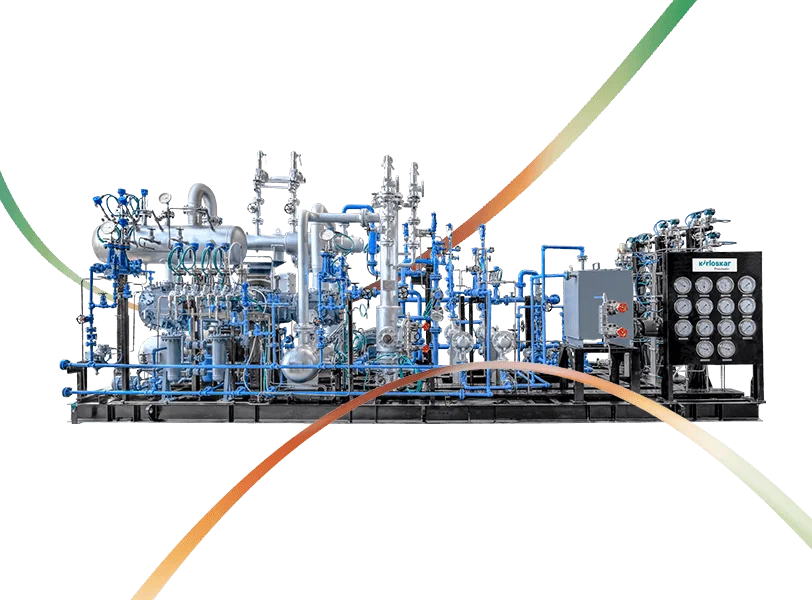

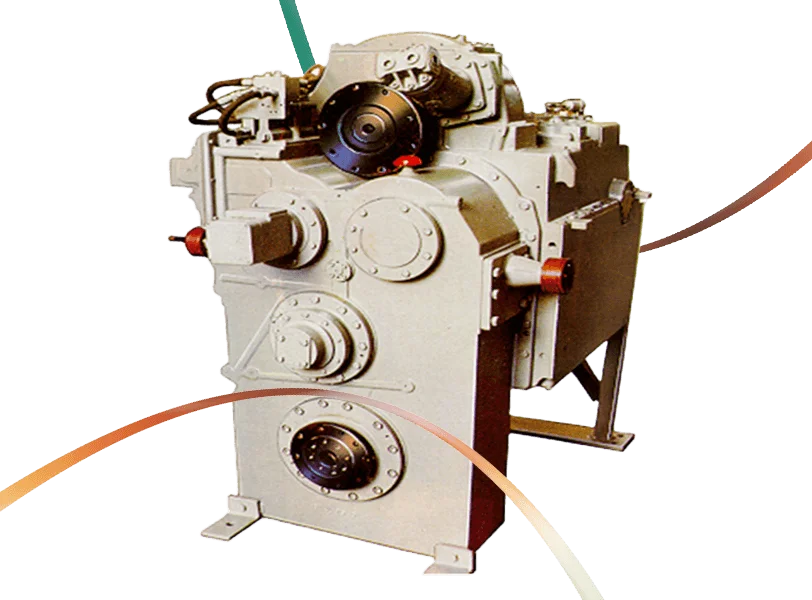

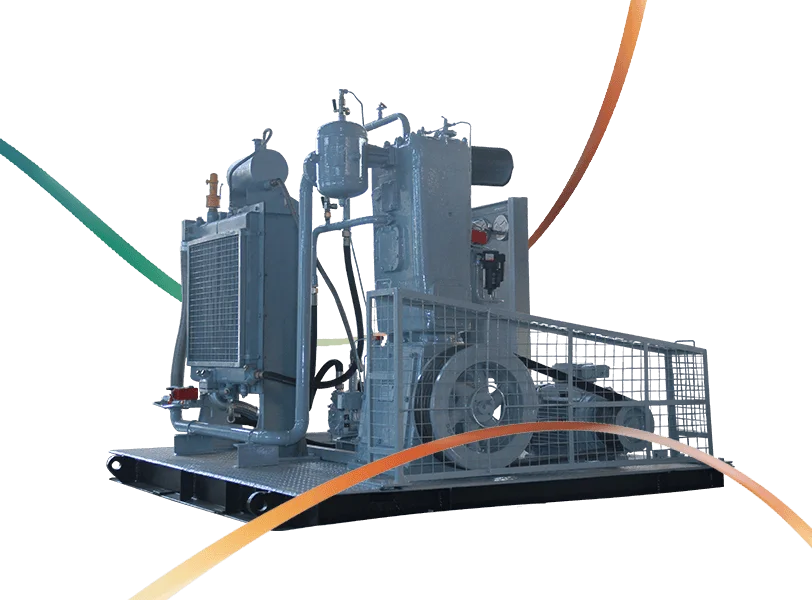

From exploration to distribution, our comprehensive portfolio ensures efficiency, reliability, and performance across every stage. Our Air Compressor Division offers robust solutions including oil-injected electric screw compressors, diesel engine-driven portable screw compressors, centrifugal and reciprocating gas compressors, available in vertical and horizontal balanced opposed configurations, to meet the industry's demanding requirements.

In Air Conditioning and Refrigeration, we deliver highly efficient screw and reciprocating refrigeration systems designed to support critical processes with precision and consistency.

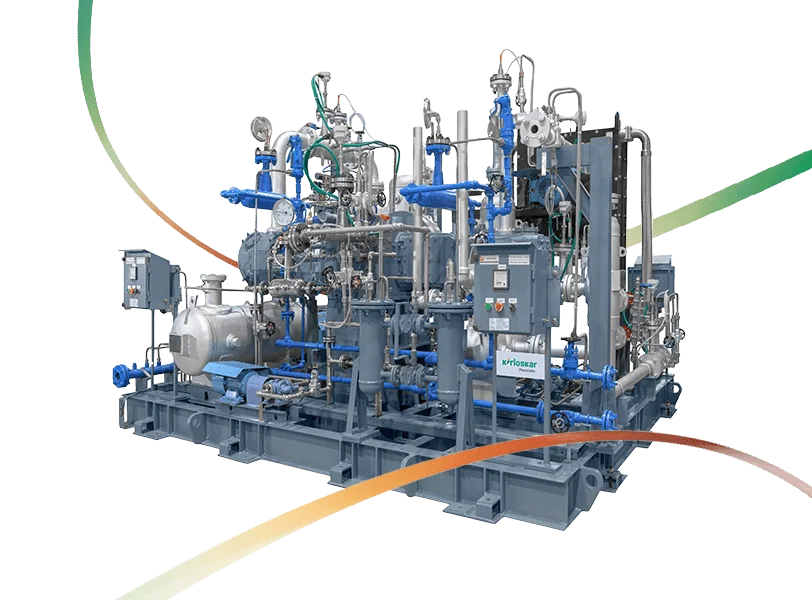

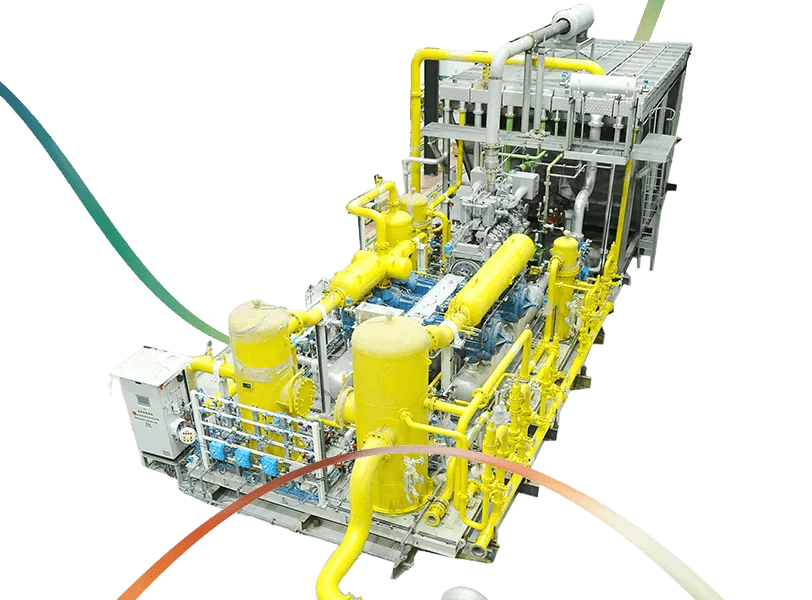

Our Process Gas Systems provide end-to-end solutions with reciprocating and screw gas compressor packages, online CNG gas compressor units, and CNG hydraulic booster packages, engineered for seamless integration and dependable operation.

At Kirloskar Pneumatic, we go beyond serving the oil and gas sector, we help shape its future with innovation, reliability, and performance-driven engineering.

OIL & GAS

Transforming resources into opportunity

Fuelling progress, driving economies, and powering the world, the oil and gas industry remains the backbone of global growth and innovation.

We, at Kirloskar Pneumatic, strengthen this foundation with cutting-edge solutions for pipeline transportation, petroleum refining, and petrochemical synthesis. Our expertise lies in designing and manufacturing refrigeration packages for various applications in the sector, along with gas compressors tailored for the CNG industry.

From exploration to distribution, our comprehensive portfolio ensures efficiency, reliability, and performance across every stage. Our Air Compressor Division offers robust solutions including oil-injected electric screw compressors, diesel engine-driven portable screw compressors, centrifugal and reciprocating gas compressors, available in vertical and horizontal balanced opposed configurations, to meet the industry's demanding requirements.

In Air Conditioning and Refrigeration, we deliver highly efficient screw and reciprocating refrigeration systems designed to support critical processes with precision and consistency.

Our Process Gas Systems provide end-to-end solutions with reciprocating and screw gas compressor packages, online CNG gas compressor units, and CNG hydraulic booster packages, engineered for seamless integration and dependable operation.

At Kirloskar Pneumatic, we go beyond serving the oil and gas sector, we help shape its future with innovation, reliability, and performance-driven engineering.

Asset Publisher

Choose Applications

Air Conditioning/Equipment Cooling | Control Room Cooling...

Wort Cooling | Air Conditioning/Equipment Cooling | Control Room Cooling...

Reactor Cooling | Coffee Extract Cooling | Recycled Bottle Cooling...

Pulp Cooling in Pasteurization | Cooling in Pasteurisation...

Wort Cooling | Air Conditioning/Equipment Cooling | Control Room Cooling...

Flare Gas Recovery | LNG | LPG | BOG | GTL | Aromatics...

Flare Gas Recovery | Process Control and Instrumentation | LNG | LPG | BOG...

Pharmaceutical Storage | Freeze Drying (Lyophilisation)...

Traction Motors

Drilling Operations | Pipeline Maintenance and Testing...

Drilling Operations | Pipeline Maintenance and Testing...

Sandblasting | Jack hammer | Excavation | DTH Drilling | Tunnelling...

Flare Gas Recovery | Fuel Gas Booster | Gas Gathering | Gas Booster...

Drilling Operations | Pipeline Maintenance and Testing...

Wort Cooling | Air Conditioning/Equipment Cooling | Control Room Cooling...

(Comfort Cooling) Air Conditioning | Air Conditioning/Equipment Cooling

Blowers and Fans | Pinion Stand | Roughing Mill | Ladle Tilters | Sizing Mill...

Speciality pumps and compressor drives | Co-generations turbines...

Steel Furnace Tilter | Turbine | Sugar Mill Drive

Sandblasting | Jack hammer | Excavation | DTH Drilling | Tunnelling...

Carbon Dioxide Liquefaction | Chemical Reactors Cooling...

Pharmaceutical Storage | Freeze Drying (Lyophilisation)...

Pharmaceutical Storage | Freeze Drying (Lyophilisation)...

Pharmaceutical Storage | Freeze Drying (Lyophilisation)...

Bulker and train unloading | Silo fluidization | Combustion air...

Chilled Water Plants | Refrigeration Plants

HVAC Plants

Chilled Water Plants | Refrigeration Plants | HVAC Plants

Chilled Water Plants | Refrigeration Plants | HVAC Plants

Chilled Water Plants | Refrigeration Plants | HVAC Plants

Wind Turbine

Shunting Locomotives Drives

Open Gears

Flare Gas Recovery | Fuel Gas Booster | Gas Gathering | Vapor Recovery...

Gas Grid Injection | Cascade Filling

NGV Filling

NGV Filling

Sandblasting | Jack hammer | Excavation | DTH Drilling | Tunnelling...

Drilling Operations | Pipeline Maintenance and Testing...

Flare Gas Recovery | LNG | LPG | BOG | GTL | Aromatics...

Asset Publisher

No results found

Polysilicon is a critical component for semiconductors and solar panels which is produced through precise temperature control during gas condensation and chemical deposition using Refrigeration Systems.

Gas-to-liquid is the chemical conversion of natural gas into liquid hydrocarbons like diesel, kerosene, and other chemicals, which is used for transportation, motor oils and other processes. Refrigeration System supports the condensation and separation of gas components during the GTL process. It provides cooling at various stages to maintain optimal reaction conditions and enhance energy efficiency by managing heat loads in the conversion process.

Composed of propane and butane, LPG refers to Liquified Petroleum Gas which is liquified for efficient storage and transportation and used as a fuel source for residential, industrial, and automotive applications. Refrigeration System Cools and liquefies propane and butane gases for efficient storage and handling. It prevents losses by re-liquefying boil-off gas, improving operational efficiency and reducing emissions. It also maintains stable storage conditions, ensuring safety and product integrity.

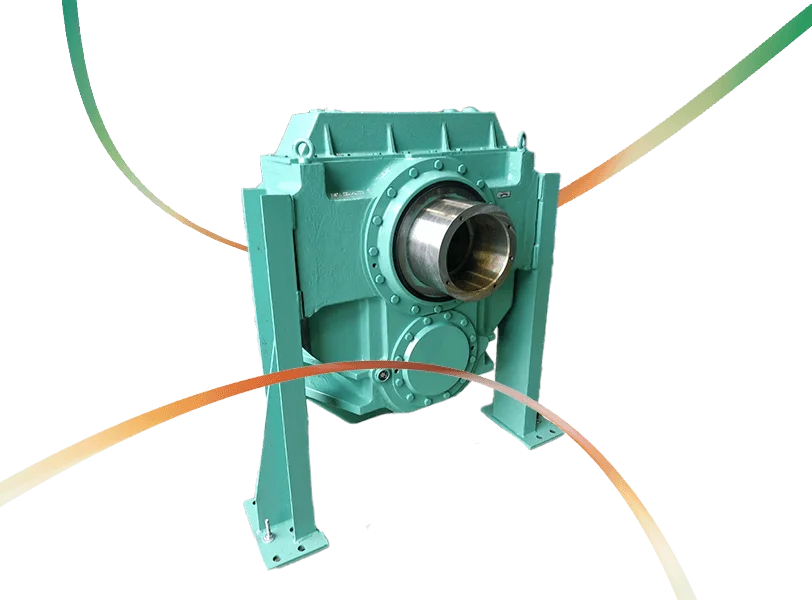

Specialty pumps and compressor drives move crude oil and inject chemicals, with variable speeds for efficiency and motor protection. High-speed gearboxes are crucial in the specialty pumps and compressor drives industry, especially for applications requiring high-torque and speed changes.

Blowers and fans move air and gas at low and high pressure for ventilation, cooling, combustion air supply and other functions. Helical and bevel Gearboxes are often used in blowers and fans to transfer power, change speed, and adjust the direction of rotation.

The process involves the removal of excess heat to cool off the recycled gases before reintroducing them back into the process. Refrigeration system cools the recycled gases to the desired temperature before reintroducing them into the process and removes excess heat from exothermic reactions, ensuring stable and efficient operation. It also enhances energy efficiency by reducing the need for fresh gas and optimising process conditions.

Boil-off gas refers to vapourised ethylene, which is reliquified to cooling temperatures for minimising product loss and maintaining safety. Refrigeration system Re-liquefies ethylene vapours by cooling them to cryogenic temperatures (-104°C) and helps maintain the storage tank pressures within safe limits while ensuring minimal product loss during handling.

Propane and Butane are extracted from hydrocarbon mixtures by cooling gas streams to separate and condense them. Refrigeration System lowers the temperature of the gas streams to condense and separate propane and butane effectively. It also enables liquefaction of these gases for storage and transport, reducing their volume and enhancing handling efficiency.

Flare Gas Recovery captures and cools hydrocarbon gases, allowing them to be separated, purified, and reused.

Synthetic rubbers such as styrene-butadiene rubber and polybutadiene rubber are produced after the polymerisation and stabilisation of rubber products. Refrigeration System supports temperature control during polymerisation and stabilisation of rubber products.

Polypropylene is a versatile polymer used in pipeline insulation, coating, and the production of storage tanks and containers. Refrigeration System ensures effective cooling during polymerisation and condensation of process gases.

This involves cooling process streams during the production of polyethene, which is a widely used plastic. Refrigeration System removes heat generated during polymerisation, ensuring product quality and process efficiency.

Solvent Recovery is the process of reclaiming solvents from chemical and petrochemical operations for reuse while reducing emissions. Refrigeration System cools and condenses vent gases or solvents, minimising emissions and enabling reuse.

Reflux Chillers reduce temperatures in the distillation process for effective separation of hydrocarbons and other compounds.

Refers to the condensation of vinyl chloride monomer vapours during its production for use in PVC manufacturing. Refrigeration System maintains the required low temperatures to condense VCM vapours, ensuring efficient recovery and process stability.

Aromatics are used to produce hydrocarbons like benzene, toluene and xylene in petrochemical plants through cooling and condensation. Refrigeration / Cooling Packages are used to cool and condense aromatic vapours during separation and purification processes.

BOG refers to Boil-Off Gas, which ensures the recovery and reuse of vapourised liquified petroleum gas during storage and transit

Refers to Liquified Natural Gas which is cooled to cryogenic temperatures (-162°C) to convert it into a liquid state for storage and transport and widely used in energy supply chains for import and export. Refrigeration System facilitates the liquefaction process by lowering the temperature of natural gas to cryogenic levels. Helps in managing boil-off gas (BOG) during storage and transportation by re-liquefying vaporised LNG. Enables compact storage, reducing the volume of natural gas by approximately 600 times.

Compressed air serves as the primary feedstock in air separation units to produce industrial gases like oxygen, nitrogen, and argon for various oil and gas processing operations.

Compressed air helps in efficient refining by acting as an energy source for pneumatic controls, operating actuators and controlling valves in refining processes.

Compressed air is used for cleaning pipelines to remove debris, operating pneumatic valves for pipeline control, and performing pressure testing (hydrostatic and pneumatic tests) for the safety of pipelines.

Compressed air powers pneumatic tools like drills and wrenches for rig assembly and maintenance. It is also used in air drilling, where compressed air lifts cuttings from the wellbore to the surface.

Cascade filling stations facilitate the storage of compressed natural gas in high-pressure cylinders or cascade storage systems allowing for rapid refuelling during peak usage by maintaining adequate pressure levels.

Gas Grid Injection is the process of introducing renewable gases like biomethane, into an existing natural gas network for distribution and use.

A Natural Gas Vehicle (NGV) filling station provides compressed natural gas as fuel for vehicles. The key component of such a station is the compressed natural gas compressor which is essential for storing and delivering natural gas at high pressures for efficient vehicle refuelling.

Flare Gas Recovery captures and compresses gases that would otherwise be flared, reducing emissions and allowing them to be separated, purified, and reused.

Fuel Gas Boosters are used to raise the pressure of fuel gas to the operating level of the gas engine or combined heat and power plant.

PSA (Pressure Swing Adsorption) tail gas application refers to utilizing the residual gas from hydrogen production or purification processes in refineries. This tail gas, which contains unseparated components like methane, carbon dioxide, and other hydrocarbons, can be either used as fuel gas for refinery heaters and boilers, improving energy efficiency or recycled back into processes to optimize hydrogen recovery and reduce waste in downstream operations.

In oil production, screw compressors are used in vapor recovery units (VRUs) to capture and compress gas vapors released during oil storage and handling, preventing emissions and enabling the recovery of valuable hydrocarbons.

Gas Gathering involves collecting natural gas and directing it into a transportation pipeline. In multi-well fields, gas compression is used to gather gas from different wells and transport it to processing facilities. This is particularly important when dealing with low-pressure gas fields.

Upstream - Upstream gas gathering is the transportation of natural gas from multiple wells to a treatment facility.

Midstream - Midstream gas gathering ensures proper flow and pressure in gathering systems through smooth transportation of treated gas.

Applied in the injection and withdrawal processes at underground storage facilities, helping to manage seasonal supply and demand fluctuations.

Utilized in natural gas processing plants for various stages of gas treatment, including dehydration, sweetening, and fractionation, where precise control of gas pressure is crucial.

Gas Pipeline Transmission moves large volumes of natural gas, while maintaining its pressure within high-pressure pipelines, over long distances from production sites to processing plants or distribution networks.

Minimum Send-Out ensures the normal operation of a liquified natural gas terminal by ensuring a minimum amount of gas is fed into the gas distribution grid continuously. MSO relates more to processing and distribution than to extraction.

Upstream - The upstream sees limited application as Minimum Send-Out prioritises extraction over processing and distribution.

Midstream - The midstream ensures a minimum volume of gas sent from processing units to ensure operational stability.

Downstream - The downstream ensures a steady supply from refineries or distribution systems to power generation facilities.

Flare gas recovery is a system that captures and reuses excess gases produced during industrial processes to minimize environmental impact and utilize valuable resources.

Upstream - The upstream minimises environmental impact by recovering and reutilising flared gas from production sites.

Midstream - The midstream enhances efficiency by recovering gas from the gas processing facilities.

Downstream - The downstream enhances operational efficiency and cuts emissions by reusing the gas from refineries.

Power Generation involves the process of converting chemical energy into electricity for field operations using gas turbines or engines, reducing reliance on external energy sources.

Upstream - The upstream minimises dependence on external energy sources by generating power for field operations using gas turbines or engines.

Midstream - The midstream generates power for pipeline compressors, pumping stations, and processing units, with gas often used to produce electricity for these operations.

Downstream - The downstream involves supplying electricity to industrial and residential consumers by using natural gas as a primary fuel.

Coal Bed Methane is a natural gas extracted by drilling wells into coal seams, often involving water removal and depressurization to release trapped gas.

Upstream - The upstream involves extracting methane gas from coal seams by removing water and reducing pressure, allowing the trapped gas to be released.

Midstream - The midstream involves the transportation or storage of methane gas via pipelines for processing unit delivery.

Downstream - The downstream involves the usage of the Coal Bed Methane as a feedstock for enhanced liquified natural gas processing or power generation.

Reinjection is the process of injecting fluids back into the pipelines to push more oil towards production wells.

Upstream - Upstream reinjection involves reinjecting gas or water to improve hydrocarbon recovery by maintaining pressure for enhanced oil recovery.

Midstream - Midstream reinjection primarily involves reinjecting extracted carbon dioxide or gas back into storage facilities or pipelines.

As reservoirs deplete, natural pressure decreases, making it harder to bring gas to the surface. Wellhead compressors boost gas pressure at the wellhead to ensure a steady flow of gas from the well.

Gas Lift reduces the hydrostatic pressure by injecting high-pressure gas into the well and lifting the oil to the surface.

A Gas Booster device is ideally suited for increasing the pressure of gas at production sites to facilitate transportation, especially when the natural reservoir pressure declines.

Upstream - An upstream gas booster ensures smooth transportation by increasing gas pressure at production sites when the pressure of the natural reservoir plummets.

Midstream - A midstream gas booster maintains gas flow in pipelines to compensate for the loss of pressure during transportation.

Downstream - A downstream gas booster pressurises gas for final end-to-end functions like processing and delivery.