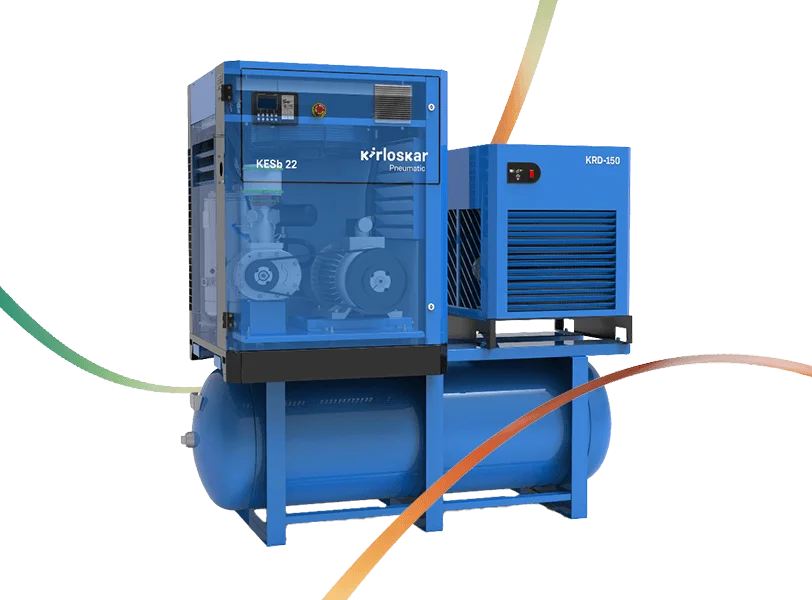

Oil Injected Electric Screw Compressor | Kirloskar Pneumatic - KPCL

Sub Product Data Content (Oil Injected Electric Screw Compressor)

Capacity:

22 to 1047 cfm

Pressure Range:

7.5 to 13 kg/cm2

Type:

Why Kirloskar Pneumatic?

Kirloskar Pneumatic offers a comprehensive range of oil-injected electric screw air compressors that are available in fixed-speed models and those using variable frequency drive technology. Our KES Series and KESe Series are tailored to meet the specific requirements of industries and enable them to achieve optimal production goals. Versatile in nature, these compressors work for small-scale and large industrial set ups, offering flexible solutions across applications.

Our oil-injected electric screw air compressors redefine energy efficiency by reducing operational costs and maximising output. They deliver consistent and dependable performance, even in the most challenging environments. Proudly made in India, we control the entire value chain, passing on the benefits of cost-efficiencies to our customers. We keep the maintenance easy and to a minimum, to ensure smooth and uninterrupted business operations.

FEATURES

- Indigenously Developed Airend - KOSMIC: The compact design of the airend makes the compressor energy-efficient and the machine’s overall performance reliable.

- Air Intake System: The guided suction filter helps lower pressure drop as well as noise, and ensures cleaner air with its two stage filtration system.

- Canopy and Base Frame: The acoustically designed modular metallic canopy reduces the noise level of the package.

- Electric Motor: With an efficiency class as per IE2, the motors are suitable for site conditions as per IP55, class F insulation.

- Air Oil Separation System: The efficient air-oil separator element limits the oil carried over to the desired level. It also ensures minimum pressure drop across the separator.

- After Cooler: The differential pressure monitoring across the cooler enables the continuous monitoring of cooler performance and detect choking.

BENEFITS

- Exceptional performance with the highest air flow delivery and lowest power consumption

- Lowest life cycle cost

- Advanced monitoring and SMART Controller

- Strategic placement of components for ease of serviceability

- Reliable and efficient compressor

- Keeping production up and running with continuous duty operation.

- Competitive initial investment cost

- Designed specially for Indian conditions such as dusty environments and high temperatures of up to 50ºC.

Why Kirloskar Pneumatic?

Kirloskar Pneumatic offers a comprehensive range of oil-injected electric screw air compressors that are available in fixed-speed models and those using variable frequency drive technology. Our KES Series and KESe Series are tailored to meet the specific requirements of industries and enable them to achieve optimal production goals. Versatile in nature, these compressors work for small-scale and large industrial set ups, offering flexible solutions across applications.

Our oil-injected electric screw air compressors redefine energy efficiency by reducing operational costs and maximising output. They deliver consistent and dependable performance, even in the most challenging environments. Proudly made in India, we control the entire value chain, passing on the benefits of cost-efficiencies to our customers. We keep the maintenance easy and to a minimum, to ensure smooth and uninterrupted business operations.

FEATURES

- Indigenously Developed Airend - KOSMIC: The compact design of the airend makes the compressor energy-efficient and the machine’s overall performance reliable.

- Air Intake System: The guided suction filter helps lower pressure drop as well as noise, and ensures cleaner air with its two stage filtration system.

- Canopy and Base Frame: The acoustically designed modular metallic canopy reduces the noise level of the package.

- Electric Motor: With an efficiency class as per IE2, the motors are suitable for site conditions as per IP55, class F insulation.

- Air Oil Separation System: The efficient air-oil separator element limits the oil carried over to the desired level. It also ensures minimum pressure drop across the separator.

- After Cooler: The differential pressure monitoring across the cooler enables the continuous monitoring of cooler performance and detect choking.

BENEFITS

- Exceptional performance with the highest air flow delivery and lowest power consumption

- Lowest life cycle cost

- Advanced monitoring and SMART Controller

- Strategic placement of components for ease of serviceability

- Reliable and efficient compressor

- Keeping production up and running with continuous duty operation.

- Competitive initial investment cost

- Designed specially for Indian conditions such as dusty environments and high temperatures of up to 50ºC.