High Speed Gearboxes | Kirloskar Pneumatic - KPCL

Sub Product Data Content (High Speed Gearboxes)

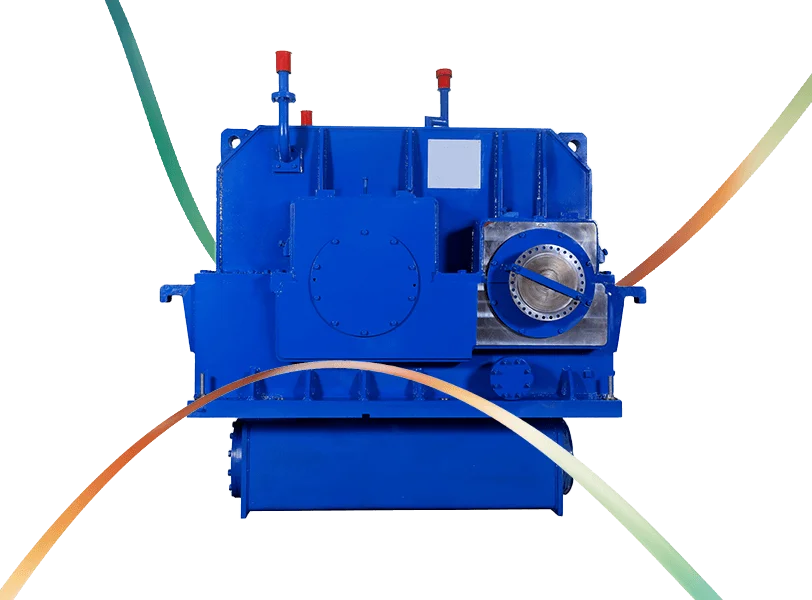

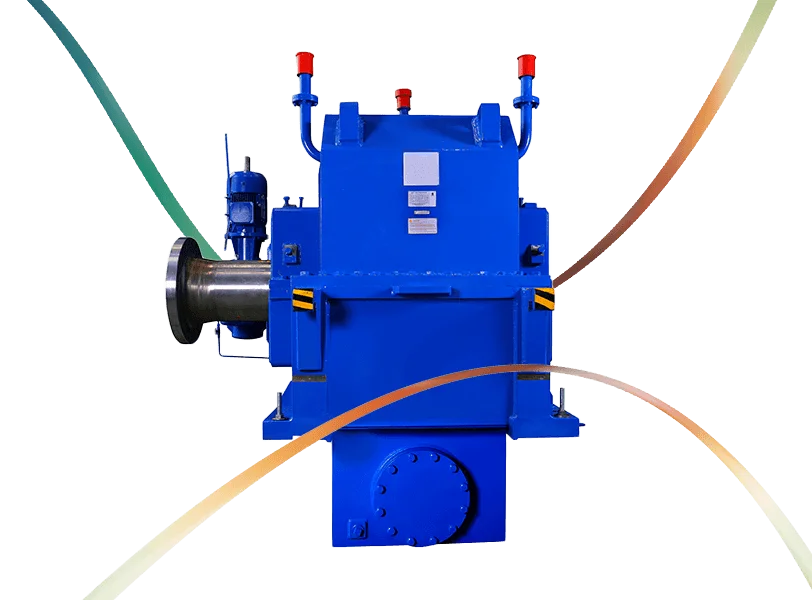

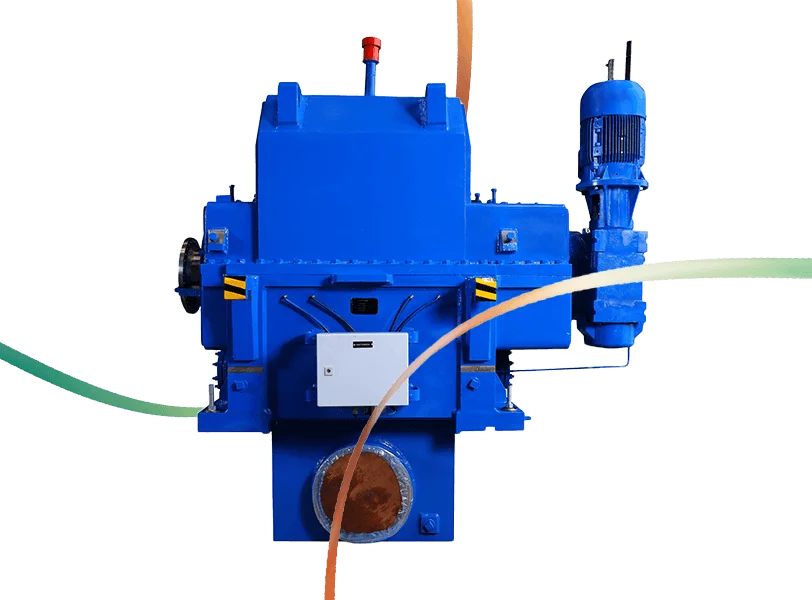

Power:

Up to 50 MW

Input Speed:

Up to 12000 RPM (Prime mover: Steam Turbine, Driven Machine –Generator)

Efficiency:

98.6 % ± 0.1 %

Type:

WHY KIRLOSKAR PNEUMATIC?

At Kirloskar Pneumatic, we bring decades of expertise and cutting-edge technology to every gearbox we design. Our experienced Transmissions Division utilises advanced gear analysis software, along with gearbox system dynamics and vibration analysis, to optimise performance and reliability. With an in-house heat treatment facility equipped with SCADA control and microstructure measurement tools, we ensure precise material properties for maximum durability. We also use 5-axis CNC machining centres for casing machining, achieving the highest levels of accuracy in every component.

Our state-of-the-art manufacturing facility features CNC gear profile grinders, ensuring the production of high-quality gears that meet the most stringent standards. To validate our designs, we have a fully equipped test facility with up to 1 MW, allowing us to verify all critical parameters and ensure that every gearbox meets performance and reliability expectations.

FEATURES

- Manufactured to AGMA or API or DIN standards

- Optimised gear teeth, bearings, natural frequencies, and rotor dynamics for minimal vibration and noise.

- Housings fabricated from E250 steel, designed with 3D modelling and FEA for rigidity; split casing for easy maintenance.

- Pinions with shafts, precision hobbed, finished ground, and heat-treated or carburized per specifications

- Case-hardened, profile-ground single or double helical gears with tip relief and crowning for quiet operation and maximum torque.

- Shafts precision machined from heat-treated alloy steel, sized per DIN 743 with stress analysis for optimal strength.

- Split, babbitt-lined journal bearings; radial tilting pad bearings for higher velocities; separate thrust bearings per API standards.

- Oil sump or external tank for lubrication; integrated pumps and coolers based on application; ISO VG 32/46 or synthetic oils for critical applications.

- Custom accessories like self-shifting clutches and couplings.

WHY KIRLOSKAR PNEUMATIC?

At Kirloskar Pneumatic, we bring decades of expertise and cutting-edge technology to every gearbox we design. Our experienced Transmissions Division utilises advanced gear analysis software, along with gearbox system dynamics and vibration analysis, to optimise performance and reliability. With an in-house heat treatment facility equipped with SCADA control and microstructure measurement tools, we ensure precise material properties for maximum durability. We also use 5-axis CNC machining centres for casing machining, achieving the highest levels of accuracy in every component.

Our state-of-the-art manufacturing facility features CNC gear profile grinders, ensuring the production of high-quality gears that meet the most stringent standards. To validate our designs, we have a fully equipped test facility with up to 1 MW, allowing us to verify all critical parameters and ensure that every gearbox meets performance and reliability expectations.

FEATURES

- Manufactured to AGMA or API or DIN standards

- Optimised gear teeth, bearings, natural frequencies, and rotor dynamics for minimal vibration and noise.

- Housings fabricated from E250 steel, designed with 3D modelling and FEA for rigidity; split casing for easy maintenance.

- Pinions with shafts, precision hobbed, finished ground, and heat-treated or carburized per specifications

- Case-hardened, profile-ground single or double helical gears with tip relief and crowning for quiet operation and maximum torque.

- Shafts precision machined from heat-treated alloy steel, sized per DIN 743 with stress analysis for optimal strength.

- Split, babbitt-lined journal bearings; radial tilting pad bearings for higher velocities; separate thrust bearings per API standards.

- Oil sump or external tank for lubrication; integrated pumps and coolers based on application; ISO VG 32/46 or synthetic oils for critical applications.

- Custom accessories like self-shifting clutches and couplings.