Chemical Industry | Kirloskar Pneumatic - KPCL

Chemical

Catalysing change that powers innovation

The chemical industry shapes modern life, supplying everything from everyday essentials to cutting-edge technologies. Playing a vital role in global food production, it ensures sustainable agriculture through essential chemical processes.

At Kirloskar Pneumatic, we support this mission by enabling efficient fertiliser manufacturing with advanced compressed air solutions. From precise material metering to seamless transport, we help sustain the world’s farms and feed growing populations.

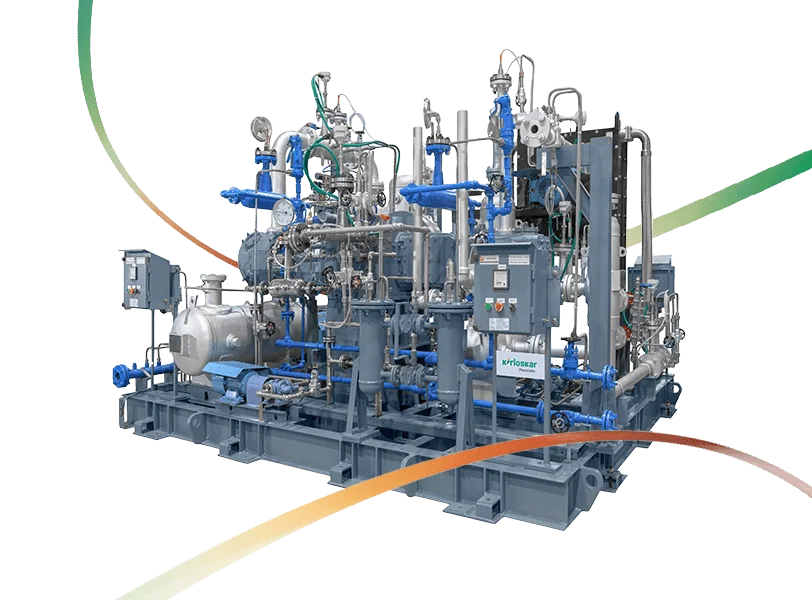

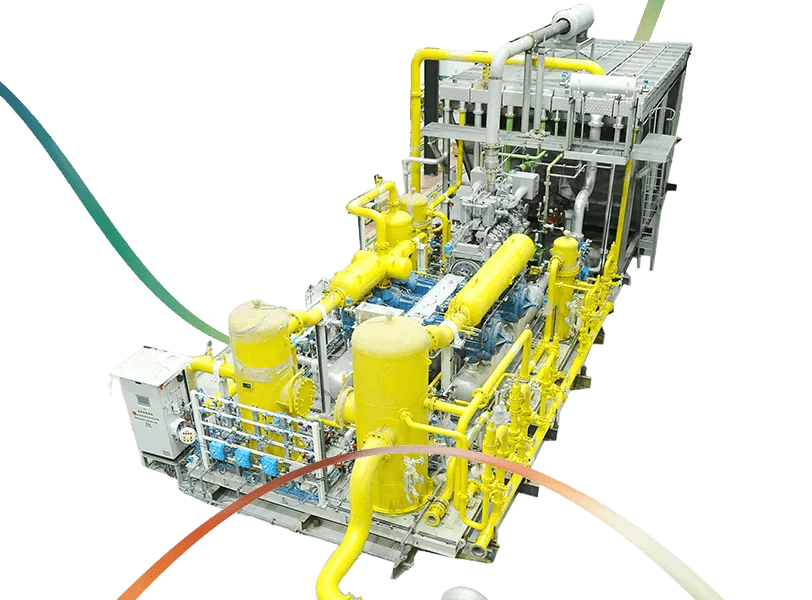

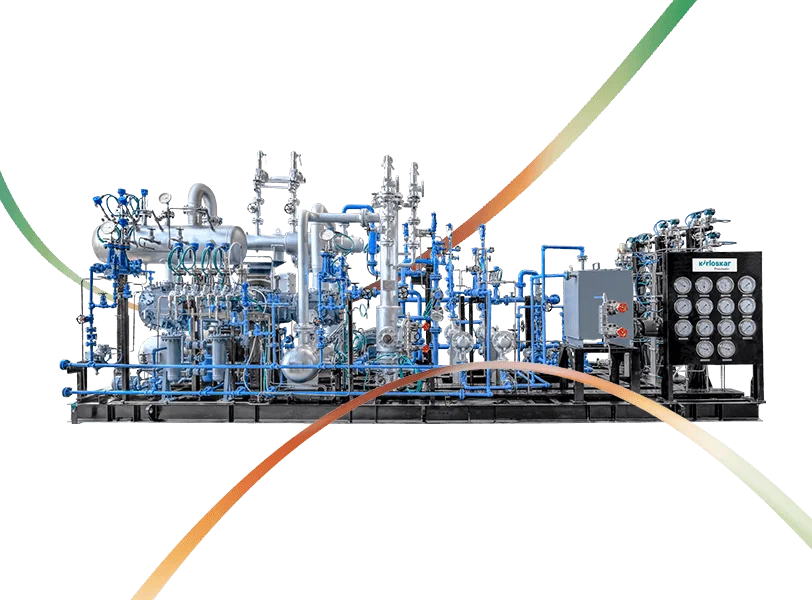

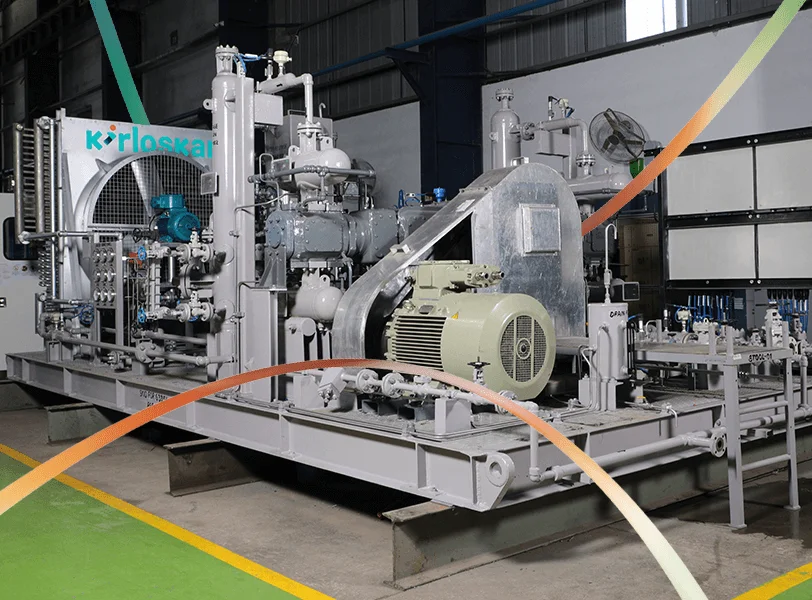

Our Air Compressor Division delivers a wide range of dependable solutions that include oil-injected electric screw compressors, centrifugal and reciprocating gas compressors, vertical and horizontal balance opposed models, as well as PET compressors, ensuring clean, efficient, and continuous operations across chemical processing units.

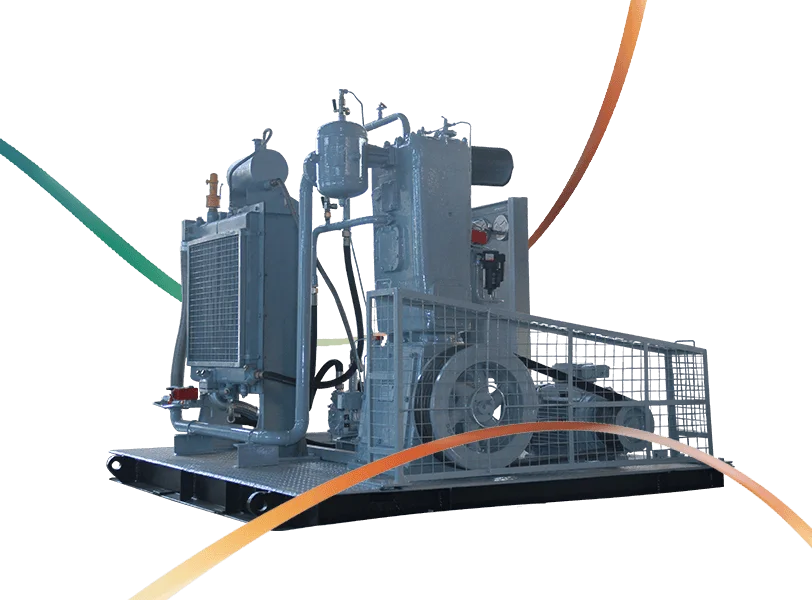

In Air Conditioning and Refrigeration, our screw and reciprocating refrigeration systems are engineered for thermal stability and process integrity, helping maintain optimal conditions for temperature-sensitive chemical reactions.

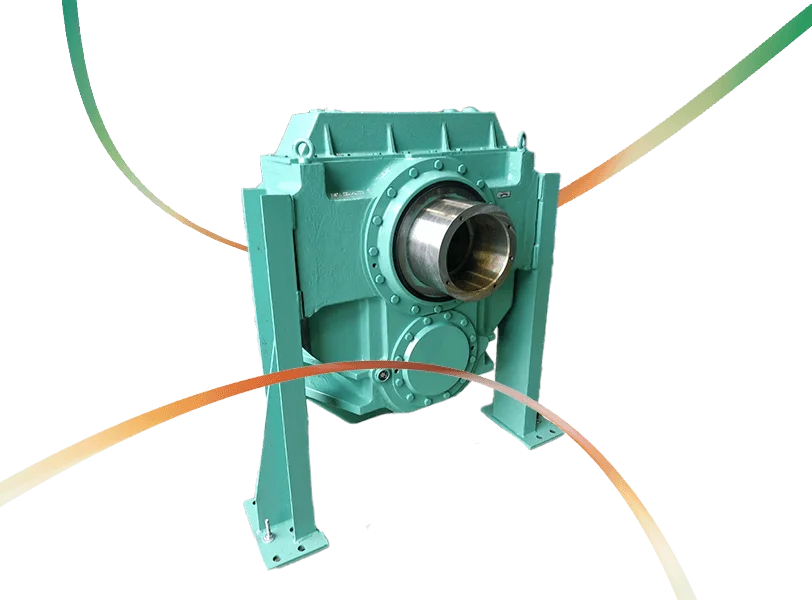

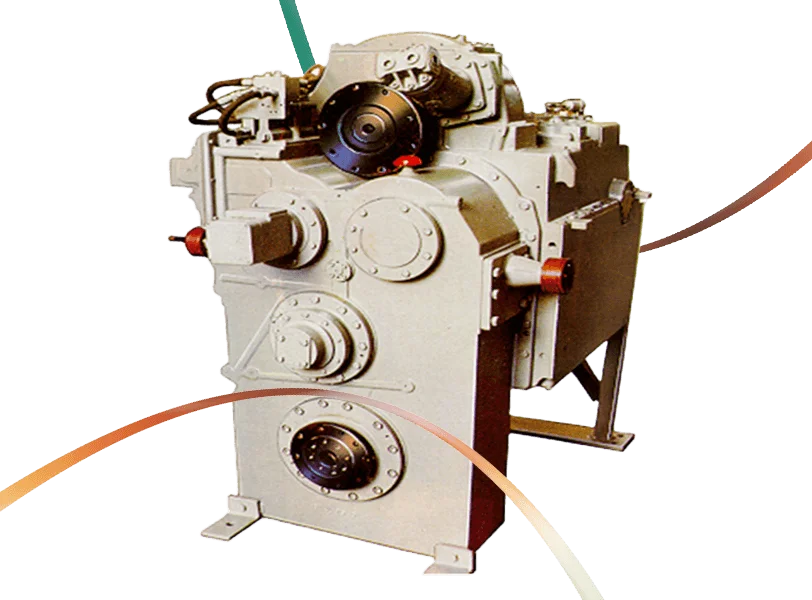

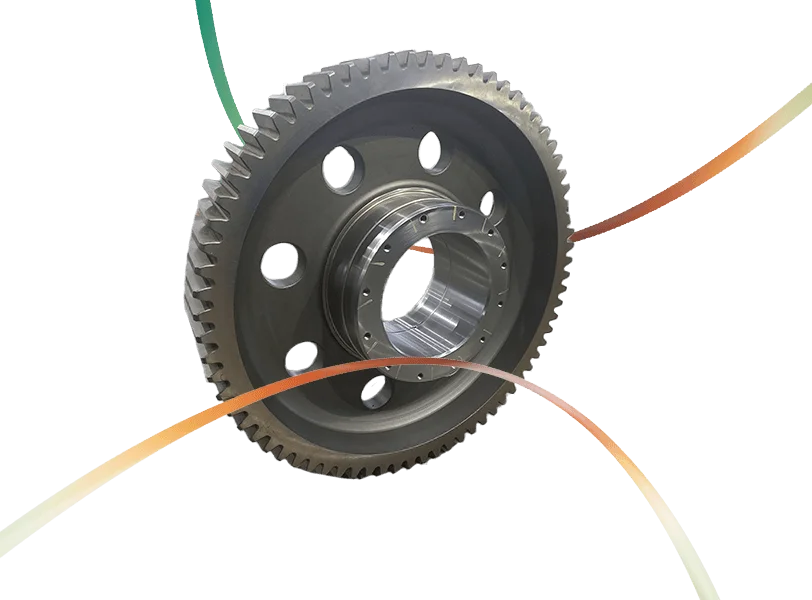

Our Transmission systems, featuring precision-engineered helical and bevel gearboxes, ensure smooth, reliable power transfer in demanding industrial environments.

At Kirloskar Pneumatic, we empower the chemical industry with precision-driven engineering, enabling innovation, efficiency, and sustainability at every stage of production.

CHEMICAL

Catalysing change that powers innovation

The chemical industry shapes modern life, supplying everything from everyday essentials to cutting-edge technologies. Playing a vital role in global food production, it ensures sustainable agriculture through essential chemical processes.

At Kirloskar Pneumatic, we support this mission by enabling efficient fertiliser manufacturing with advanced compressed air solutions. From precise material metering to seamless transport, we help sustain the world’s farms and feed growing populations.

Our Air Compressor Division delivers a wide range of dependable solutions that include oil-injected electric screw compressors, centrifugal and reciprocating gas compressors, vertical and horizontal balance opposed models, as well as PET compressors, ensuring clean, efficient, and continuous operations across chemical processing units.

In Air Conditioning and Refrigeration, our screw and reciprocating refrigeration systems are engineered for thermal stability and process integrity, helping maintain optimal conditions for temperature-sensitive chemical reactions.

Our Transmission systems, featuring precision-engineered helical and bevel gearboxes, ensure smooth, reliable power transfer in demanding industrial environments.

At Kirloskar Pneumatic, we empower the chemical industry with precision-driven engineering, enabling innovation, efficiency, and sustainability at every stage of production.

Asset Publisher

Choose Applications

Air Conditioning/Equipment Cooling | Control Room Cooling...

Wort Cooling | Air Conditioning/Equipment Cooling | Control Room Cooling...

Reactor Cooling | Coffee Extract Cooling | Recycled Bottle Cooling...

Pulp Cooling in Pasteurization | Cooling in Pasteurisation...

Wort Cooling | Air Conditioning/Equipment Cooling | Control Room Cooling...

Flare Gas Recovery | LNG | LPG | BOG | GTL | Aromatics...

Flare Gas Recovery | Process Control and Instrumentation | LNG | LPG | BOG...

Pharmaceutical Storage | Freeze Drying (Lyophilisation)...

Traction Motors

Drilling Operations | Pipeline Maintenance and Testing...

Drilling Operations | Pipeline Maintenance and Testing...

Sandblasting | Jack hammer | Excavation | DTH Drilling | Tunnelling...

Flare Gas Recovery | Fuel Gas Booster | Gas Gathering | Gas Booster...

Drilling Operations | Pipeline Maintenance and Testing...

Wort Cooling | Air Conditioning/Equipment Cooling | Control Room Cooling...

(Comfort Cooling) Air Conditioning | Air Conditioning/Equipment Cooling

Blowers and Fans | Pinion Stand | Roughing Mill | Ladle Tilters | Sizing Mill...

Speciality pumps and compressor drives | Co-generations turbines...

Steel Furnace Tilter | Turbine | Sugar Mill Drive

Sandblasting | Jack hammer | Excavation | DTH Drilling | Tunnelling...

Carbon Dioxide Liquefaction | Chemical Reactors Cooling...

Pharmaceutical Storage | Freeze Drying (Lyophilisation)...

Pharmaceutical Storage | Freeze Drying (Lyophilisation)...

Pharmaceutical Storage | Freeze Drying (Lyophilisation)...

Bulker and train unloading | Silo fluidization | Combustion air...

Chilled Water Plants | Refrigeration Plants

HVAC Plants

Chilled Water Plants | Refrigeration Plants | HVAC Plants

Chilled Water Plants | Refrigeration Plants | HVAC Plants

Chilled Water Plants | Refrigeration Plants | HVAC Plants

Wind Turbine

Shunting Locomotives Drives

Open Gears

Flare Gas Recovery | Fuel Gas Booster | Gas Gathering | Vapor Recovery...

Gas Grid Injection | Cascade Filling

NGV Filling

NGV Filling

Sandblasting | Jack hammer | Excavation | DTH Drilling | Tunnelling...

Drilling Operations | Pipeline Maintenance and Testing...

Flare Gas Recovery | LNG | LPG | BOG | GTL | Aromatics...

Asset Publisher

No results found

Secondary condenser of distillation column cools distillation vapour to condense it into a liquid.

Bulk Conveying uses air pressure to transport powders, granules, and other bulk materials through pipelines safely. Helical and bevel gearboxes are essential for bulk conveying as they enable efficient power transmission and speed reduction for equipment like conveyors, mixers, and elevators. Bevel gearboxes are used primarily when power needs to be transmitted at a 90-degree angle.

Agitators use compressed air for mixing, blending, and facilitating chemical reactions and ensuring consistency. Helical and bevel gearboxes offer a reliable and efficient solution for powering agitators where high-torque and smooth power transmission are needed, particularly in applications where a 90 degree angle is required between the motor and the agitator shaft.

Mechanical Vapour Recompression relies on refrigeration systems for compressing and condensing vapours to reuse them as a heat source.

Lime or calcium oxide is produced from limestone after the gases generated in the kiln are cooled to condense impurities.

Ammonia is produced after the removal of heat from exothermic reactions and the cooling of synthetic gases. Refrigeration System supports separation and purification of ammonia from unreacted gases.

Nitric acid is produced by oxidising ammonia, with gases cooled during the oxidation and condensation process.

Urea Plants provide cooling for the synthesis and granulation process in the reaction between ammonia and carbon dioxide. Refrigeration System ensures optimal reaction conditions for maximum yield and product quality.

Ammonia is kept at its boiling point to stay in its liquid form for use in fertilisers, refrigeration systems and industrial processes.

Water Chilling Plants remove heat from the water, providing consistent cooling for processes and comfort cooling in buildings.

Chlorine Liquefaction relies on refrigeration systems to lower the gas temperature and maintain stable conditions for storage. Refrigeration is essential for cooling chlorine gas to its liquefaction point (-34°C at atmospheric pressure).

Solvent Recovery recovers solvents for reuse through controlled condensation.

Ideal environmental conditions for production are achieved by maintaining optimal temperature and controlling humidity.

Air Conditioning provides a controlled environment for various production processes.

Reactor Cooling maintains precise temperatures for optimal reactions and product quality.

Carbon dioxide liquefaction relies on refrigeration compressors to lower the gas temperature and condense it below ambient levels.

Freeze drying, or Lyophilisation, is a low-temperature dehydration process that removes water from heat-sensitive pharmaceutical products and chemicals to elongate their shelf-life.

In processes like distillation and solvent recovery, condensing vapours into liquids prevents the loss of volatile substances.

The efficiency of chemical processes is ensured through temperature control of the exothermic and endothermic reactions.

Compressed air is used to accelerate product drying by removing moisture and facilitating evaporation.

Nitrogen is generated by filtering air via a membrane which is used in a variety of chemical applications.

Compressed air powers pneumatic control valves and instruments for precise monitoring and control of chemical processes.

Compressed air atomises liquid feed into fine droplets in spray dryers for the production of consistent powder products in the chemical industry.