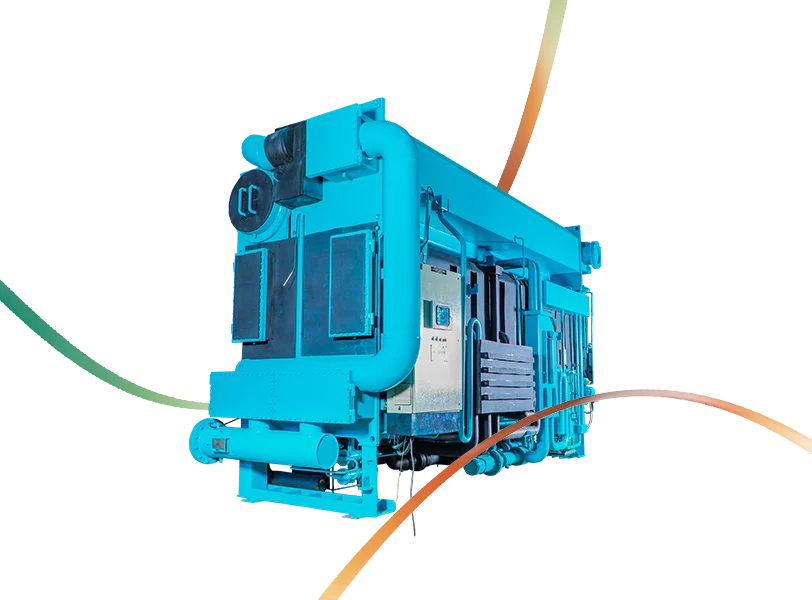

Customised Vapour Absorption Chillers Solutions - KPCL

Sub Product Data Content (Customised Vapour Absorption Chiller Solutions)

Capacity (Composite Chiller):

25 to 200 TR

Capacity (Zero Degree VAC):

50 to 1000 TR

Capacity (Ultra Low Vapour Pressure VAC):

50 of 1000 TR

Capacity (Chiller + Hot Water Generator):

Cooling Capacity: 50 to 2000 TR

Capacity (Chiller + Hot Water Generator):

Heating Capacity: 130 to 5275 kW

Type:

Why Kirloskar Pneumatic?

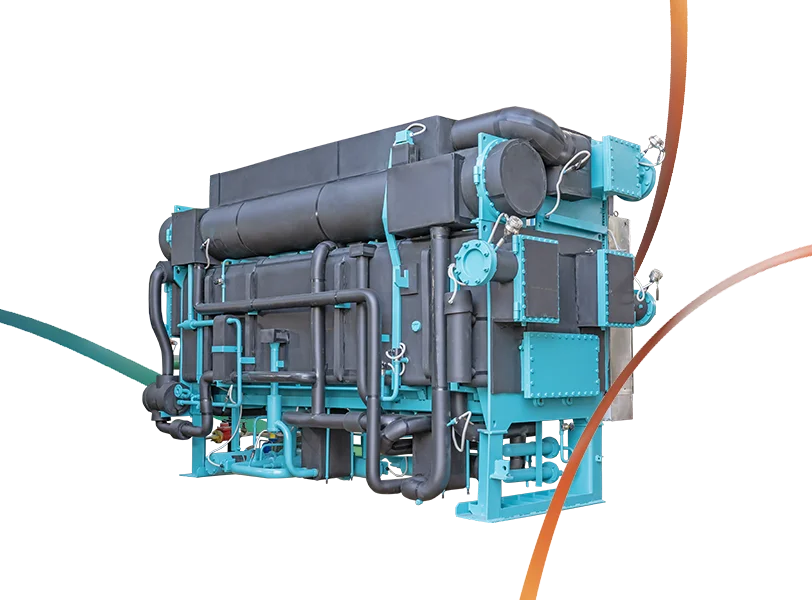

Kirloskar Pneumatic’s non-standard vapour absorption chillers provide a versatile, energy-efficient, and environmentally friendly solution for industrial and process cooling applications. By offering customised solutions tailored to the specific needs of each application, these chillers ensure optimal performance and reliability. With advanced features and robust design, our non-standard vapour absorption chillers set new benchmarks for efficiency and sustainability in industrial refrigeration.

FEATURES

- Non-standard vapour absorption chillers are specifically engineered to meet the unique demands of various industrial processes.

- These chillers utilise waste heat or low-grade heat sources, significantly reducing energy consumption and operational costs.

- These chillers use water as the refrigerant and lithium bromide (LiBr) as the absorbent.

- Equipped with state-of-the-art PLC-based control systems to ensure optimal performance at all times.

- Built to withstand harsh industrial environments, Kirloskar Pneumatic’s non-standard vapour absorption chillers are known for their durability and long-term reliability.

BENEFITS

- Customised Solutions: The customisation ensures that each chiller operates at peak efficiency, tailored to the specific cooling requirements of the application.

- Energy Efficiency: By harnessing untapped energy sources, they offer a sustainable and cost-effective cooling solution.

- Versatility: Designed to handle a wide range of temperatures and capacities, non-standard vapour absorption chillers are suitable for a variety of industrial applications, from chemical processing and pharmaceuticals to food and beverage production.

- Environmentally Friendly: Using water as the refrigerant and lithium bromide (LiBr) as the absorbent, these chillers offer an eco-friendly alternative to traditional refrigeration systems that rely on chemical refrigerants. This helps in reducing the environmental footprint of industrial cooling operations.

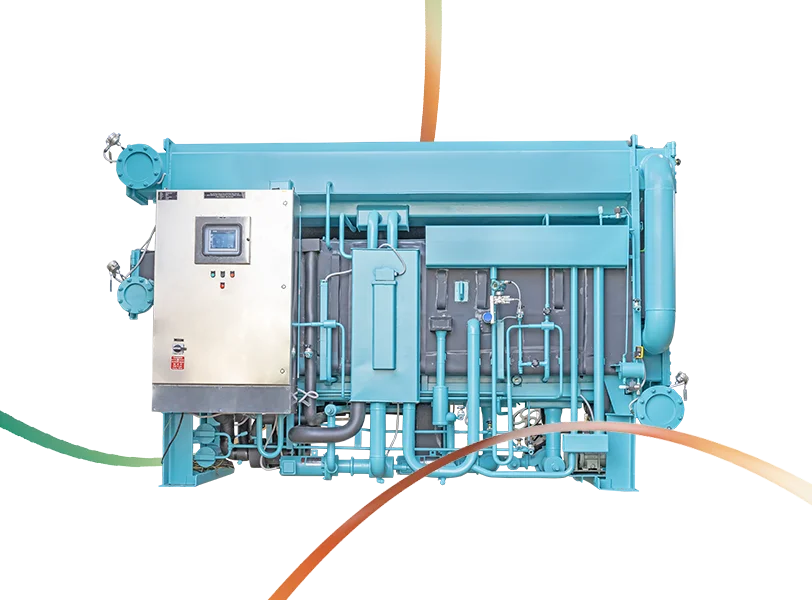

- Advanced Control Systems: These chillers provide precise and reliable operation. The user-friendly interfaces allow for easy monitoring and adjustments, ensuring optimal performance at all times.

- Robust Design: Their robust design ensures minimal maintenance and downtime.

Why Kirloskar Pneumatic?

Kirloskar Pneumatic’s non-standard vapour absorption chillers provide a versatile, energy-efficient, and environmentally friendly solution for industrial and process cooling applications. By offering customised solutions tailored to the specific needs of each application, these chillers ensure optimal performance and reliability. With advanced features and robust design, our non-standard vapour absorption chillers set new benchmarks for efficiency and sustainability in industrial refrigeration.

FEATURES

- Non-standard vapour absorption chillers are specifically engineered to meet the unique demands of various industrial processes.

- These chillers utilise waste heat or low-grade heat sources, significantly reducing energy consumption and operational costs.

- These chillers use water as the refrigerant and lithium bromide (LiBr) as the absorbent.

- Equipped with state-of-the-art PLC-based control systems to ensure optimal performance at all times.

- Built to withstand harsh industrial environments, Kirloskar Pneumatic’s non-standard vapour absorption chillers are known for their durability and long-term reliability.

BENEFITS

- Customised Solutions: The customisation ensures that each chiller operates at peak efficiency, tailored to the specific cooling requirements of the application.

- Energy Efficiency: By harnessing untapped energy sources, they offer a sustainable and cost-effective cooling solution.

- Versatility: Designed to handle a wide range of temperatures and capacities, non-standard vapour absorption chillers are suitable for a variety of industrial applications, from chemical processing and pharmaceuticals to food and beverage production.

- Environmentally Friendly: Using water as the refrigerant and lithium bromide (LiBr) as the absorbent, these chillers offer an eco-friendly alternative to traditional refrigeration systems that rely on chemical refrigerants. This helps in reducing the environmental footprint of industrial cooling operations.

- Advanced Control Systems: These chillers provide precise and reliable operation. The user-friendly interfaces allow for easy monitoring and adjustments, ensuring optimal performance at all times.

- Robust Design: Their robust design ensures minimal maintenance and downtime.

Why Kirloskar Pneumatic?

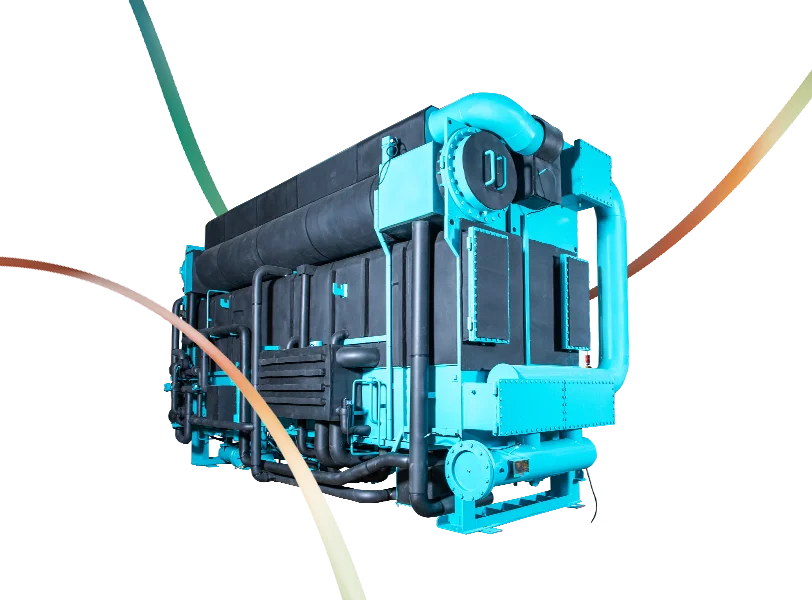

Kirloskar Pneumatic’s non-standard vapour absorption chillers provide a versatile, energy-efficient, and environmentally friendly solution for industrial and process cooling applications. By offering customised solutions tailored to the specific needs of each application, these chillers ensure optimal performance and reliability. With advanced features and robust design, our non-standard vapour absorption chillers set new benchmarks for efficiency and sustainability in industrial refrigeration.

FEATURES

- Non-standard vapour absorption chillers are specifically engineered to meet the unique demands of various industrial processes.

- These chillers utilise waste heat or low-grade heat sources, significantly reducing energy consumption and operational costs.

- These chillers use water as the refrigerant and lithium bromide (LiBr) as the absorbent.

- Equipped with state-of-the-art PLC-based control systems to ensure optimal performance at all times.

- Built to withstand harsh industrial environments, Kirloskar Pneumatic’s non-standard vapour absorption chillers are known for their durability and long-term reliability.

BENEFITS

- Customised Solutions: The customisation ensures that each chiller operates at peak efficiency, tailored to the specific cooling requirements of the application.

- Energy Efficiency: By harnessing untapped energy sources, they offer a sustainable and cost-effective cooling solution.

- Versatility: Designed to handle a wide range of temperatures and capacities, non-standard vapour absorption chillers are suitable for a variety of industrial applications, from chemical processing and pharmaceuticals to food and beverage production.

- Environmentally Friendly: Using water as the refrigerant and lithium bromide (LiBr) as the absorbent, these chillers offer an eco-friendly alternative to traditional refrigeration systems that rely on chemical refrigerants. This helps in reducing the environmental footprint of industrial cooling operations.

- Advanced Control Systems: These chillers provide precise and reliable operation. The user-friendly interfaces allow for easy monitoring and adjustments, ensuring optimal performance at all times.

- Robust Design: Their robust design ensures minimal maintenance and downtime.

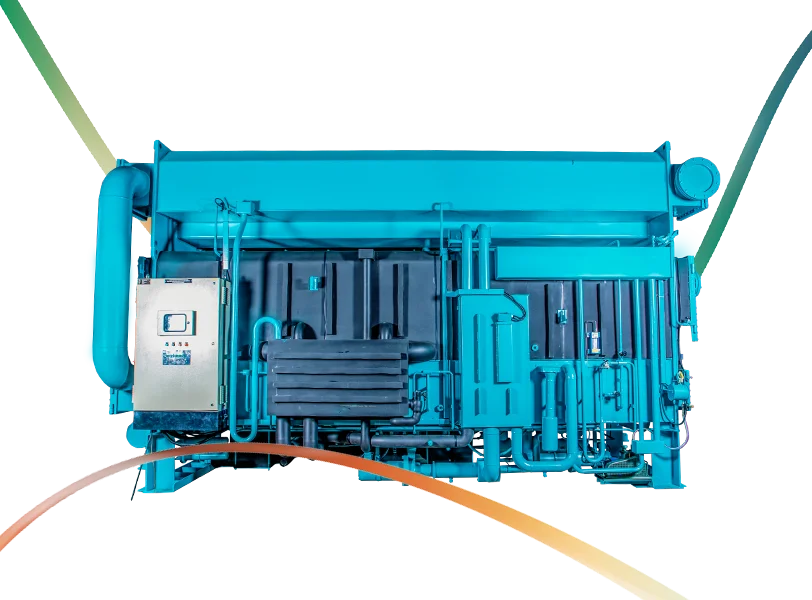

Why Kirloskar Pneumatic?

Kirloskar Pneumatic’s non-standard vapour absorption chillers provide a versatile, energy-efficient, and environmentally friendly solution for industrial and process cooling applications. By offering customised solutions tailored to the specific needs of each application, these chillers ensure optimal performance and reliability. With advanced features and robust design, our non-standard vapour absorption chillers set new benchmarks for efficiency and sustainability in industrial refrigeration.

FEATURES

- Non-standard vapour absorption chillers are specifically engineered to meet the unique demands of various industrial processes.

- These chillers utilise waste heat or low-grade heat sources, significantly reducing energy consumption and operational costs.

- These chillers use water as the refrigerant and lithium bromide (LiBr) as the absorbent.

- Equipped with state-of-the-art PLC-based control systems to ensure optimal performance at all times.

- Built to withstand harsh industrial environments, Kirloskar Pneumatic’s non-standard vapour absorption chillers are known for their durability and long-term reliability.

BENEFITS

- Customised Solutions: The customisation ensures that each chiller operates at peak efficiency, tailored to the specific cooling requirements of the application.

- Energy Efficiency: By harnessing untapped energy sources, they offer a sustainable and cost-effective cooling solution.

- Versatility: Designed to handle a wide range of temperatures and capacities, non-standard vapour absorption chillers are suitable for a variety of industrial applications, from chemical processing and pharmaceuticals to food and beverage production.

- Environmentally Friendly: Using water as the refrigerant and lithium bromide (LiBr) as the absorbent, these chillers offer an eco-friendly alternative to traditional refrigeration systems that rely on chemical refrigerants. This helps in reducing the environmental footprint of industrial cooling operations.

- Advanced Control Systems: These chillers provide precise and reliable operation. The user-friendly interfaces allow for easy monitoring and adjustments, ensuring optimal performance at all times.

- Robust Design: Their robust design ensures minimal maintenance and downtime.