Reciprocating Gas Compressor | Kirloskar Pneumatic - KPCL

Sub Product Data Content (Reciprocating Gas Compressor)

Capacity:

Up to 11,000 m3/hr

Pressure:

Up to 400 kg/cm2 (g)

WHY KIRLOSKAR PNEUMATIC?

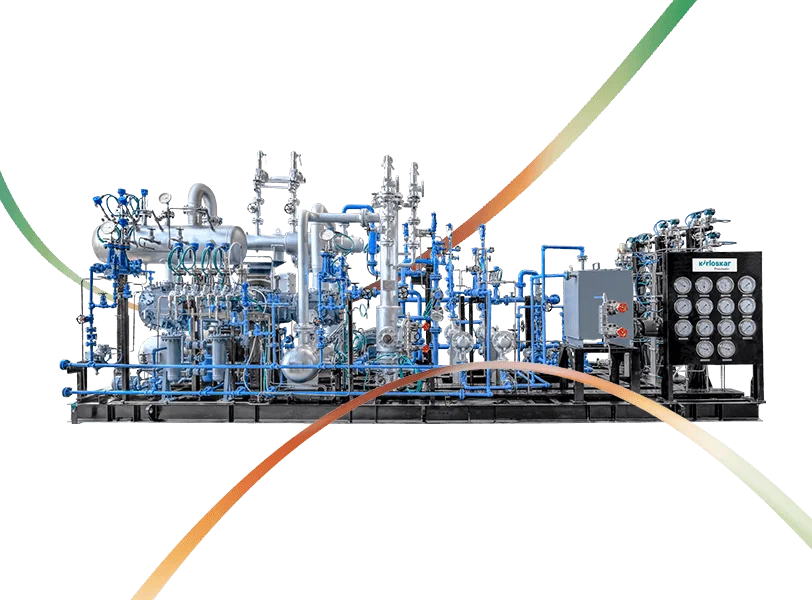

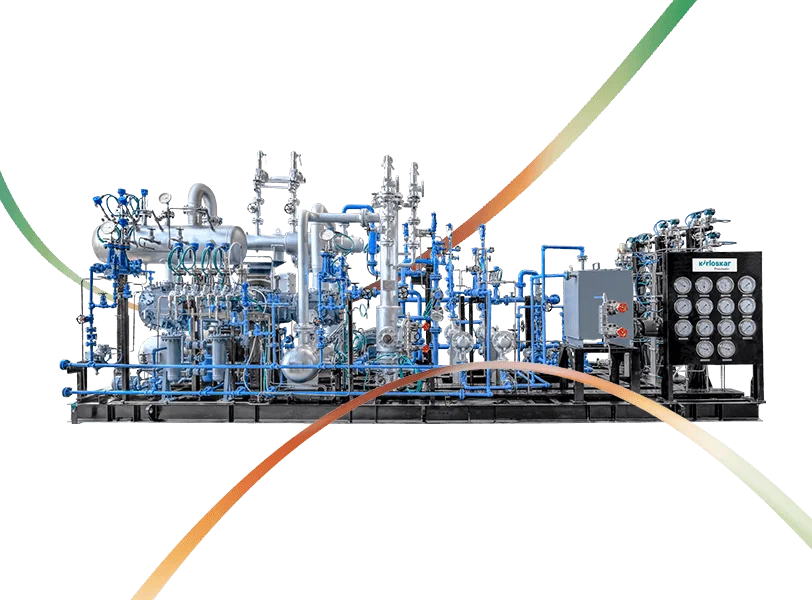

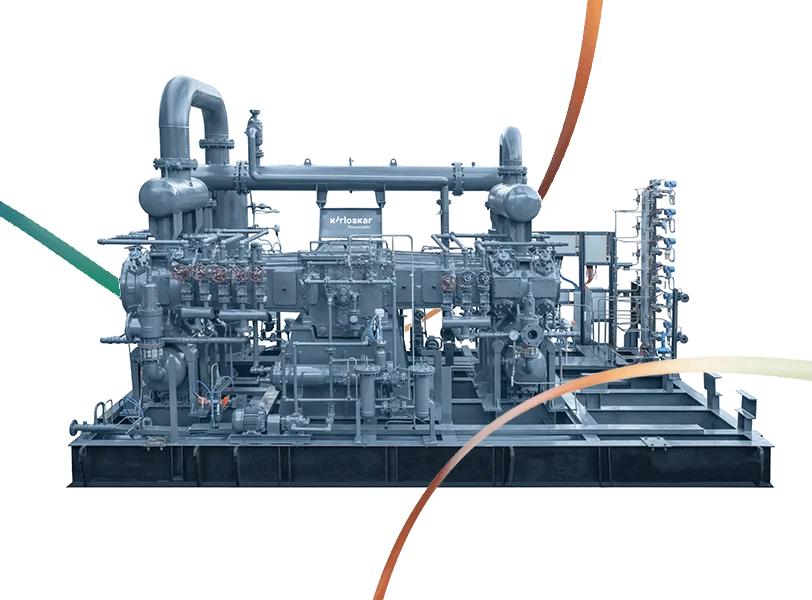

Our gas compressors are designed to be modular, economical, and reliable, providing efficient industrial gas solutions tailored to the specific needs of our customers. With unmatched expertise in engineered machines, we offer comprehensive, end-to-end solutions for gas compressors, ensuring optimal performance across a range of applications. Our wide selection of reciprocating gas compressors can accommodate various gases and gas mixtures such as Dry Cracked Ammonia (Hydrogen Rich), Crude Gas (Mixture of C2F4 & R22), Tetrafluorethylene (TEF), Carbon Dioxide (Dry & Wet), Bone Dry Nitrogen, Syngas, Biogas, Natural Gas, Co2, LPG, Ammonia, Hydrogen, Acetaldehyde, Vinyl Chloride, Recycled Gas, Methane, Propane, Inert Gases, Freon, Argon, Methyl Chloride and many more.

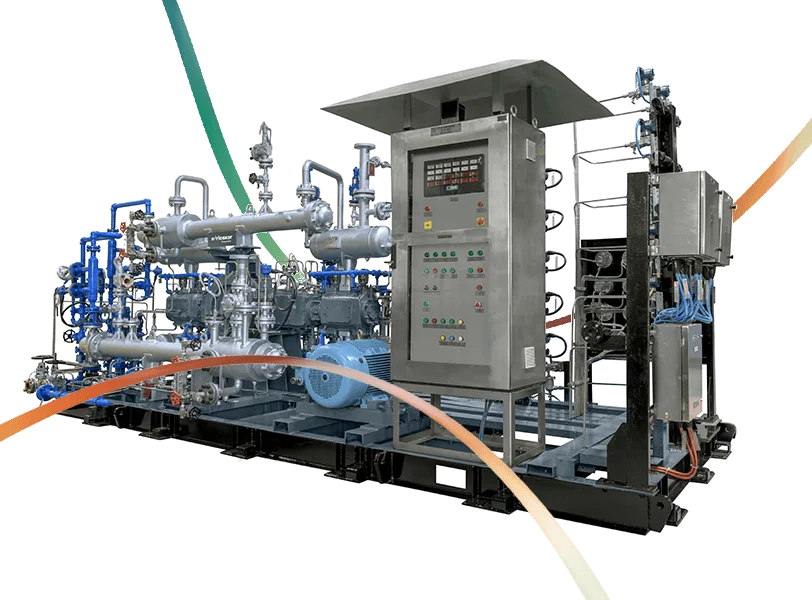

Our compressors are built to be energy efficient, with proven cylinder groups available in diameters ranging from 18mm to 660mm. This versatility allows for a broad range of flow rates and pressures to suit different operational needs. We also prioritise safety and quality by ensuring that all our compressors comply with international design standards. Each unit undergoes rigorous pre-testing for leak-proofing and performance, guaranteeing that the final product meets the highest operational standards and delivers reliable, efficient performance throughout its lifecycle. Known for their reliability, Kirloskar Pneumatic reciprocating gas compressors provide proven solutions for industrial gas compression, maintaining high performance even in low and medium-speed applications.

FEATURES

- Self lubricating piston and rider rings: Designed with special rider rings to ensure longer, uninterrupted duty cycles.

- Ribbed crankcase: Robust crankcase housing with ribbed design to withstand heavy duty operation.

- Heavy Duty Cylinder: A heavy duty cylinder design tested to be able to withstand 1.5 times the rated pressure to ensure maximum strength.

- Perfect Crosshead: Machine finished crosshead manufacturing that guarantees perfect, smooth guiding.

- Lightweight pistons: Reduced weight in pistons allows for easier change in momentum, thus improving energy savings.

- Plate Valves: Plate design valves with higher flow area to increase efficiency, are fitted as standard.

BENEFITS

- Highest air flow delivery and lowest power consumption

- Lower total operating and lifecycle cost

- Minimal vibration and noise

- Ready to install with no special foundations required

- Advance monitoring and SMART Controller

- Reliable and efficient compressor even in high altitudes and high temperatures

- Continuous, uninterrupted operation

- Oil-free operation

- Low carbon footprint