KCX Series - Reciprocating Compressors | Kirloskar Pneumatic - KPCL

Sub Product Data Content ( KCX Reciprocating RP ACR)

Capacity:

10 to 500 TR

Temperature:

-45°C to 5°C

Type:

Why Kirloskar Pneumatic?

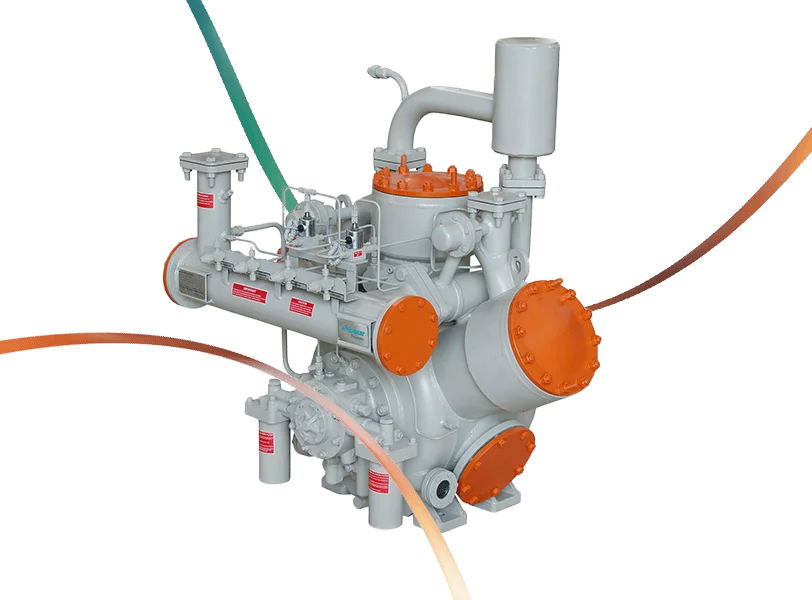

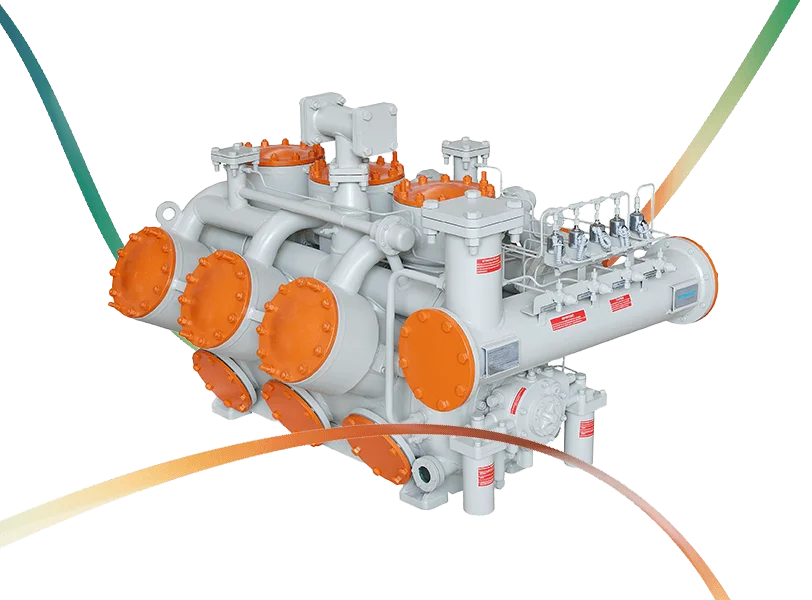

The Kirloskar range of KCX reciprocating compressors are air cooled, eliminating the need for jacket water cooling thus preventing corrosion and rusting of the crankcase. They are designed to operate with Ammonia, R22 and other HFC refrigerants. Built for industrial low temperature & large-scale refrigeration applications, they are best suited for continuous duty process refrigeration.

Features

- Fabricated Modular Rugged Construction: Built for durability and long service life in demanding industrial environments.

- Superior COP Values at Full Part Load Operation: Ensures maximum energy efficiency and optimal performance.

- Smart Monitoring and Control - KRMS: Advanced control system for real-time monitoring, enhanced diagnostics, and improved operational efficiency.

- Low Vibration and Noise Levels: Designed for smooth and quiet operation, enhancing workplace safety and comfort.

- Versatile Refrigerant Compatibility: Supports R717 (Ammonia) and other refrigerants like R134a, R22, R404A, R407C, R410A, R502 R507, catering to diverse industrial applications.

Benefits

- Energy Efficiency and Cost Savings: Reduced power consumption lowers operating expenses and enhances sustainability.

- Lowest Cost of Ownership: Optimised design and high reliability lead to minimal maintenance costs and extended service life.

- Reliable Performance in Tough Conditions: Engineered for high uptime and stable operation across varied industrial applications.

- Seamless Integration & Smart Control: KRMS enhances automation, enabling predictive maintenance and remote monitoring.

Why Kirloskar Pneumatic?

The Kirloskar range of KCX reciprocating compressors are air cooled, eliminating the need for jacket water cooling thus preventing corrosion and rusting of the crankcase. They are designed to operate with Ammonia, R22 and other HFC refrigerants. Built for industrial low temperature & large-scale refrigeration applications, they are best suited for continuous duty process refrigeration.

Features

- Fabricated Modular Rugged Construction: Built for durability and long service life in demanding industrial environments.

- Superior COP Values at Full Part Load Operation: Ensures maximum energy efficiency and optimal performance.

- Smart Monitoring and Control - KRMS: Advanced control system for real-time monitoring, enhanced diagnostics, and improved operational efficiency.

- Low Vibration and Noise Levels: Designed for smooth and quiet operation, enhancing workplace safety and comfort.

- Versatile Refrigerant Compatibility: Supports R717 (Ammonia) and other refrigerants like R134a, R22, R404A, R407C, R410A, R502 R507, catering to diverse industrial applications.

Benefits

- Energy Efficiency and Cost Savings: Reduced power consumption lowers operating expenses and enhances sustainability.

- Lowest Cost of Ownership: Optimised design and high reliability lead to minimal maintenance costs and extended service life.

- Reliable Performance in Tough Conditions: Engineered for high uptime and stable operation across varied industrial applications.

- Seamless Integration Smart Control:KRMS enhances automation, enabling predictive maintenance and remote monitoring.