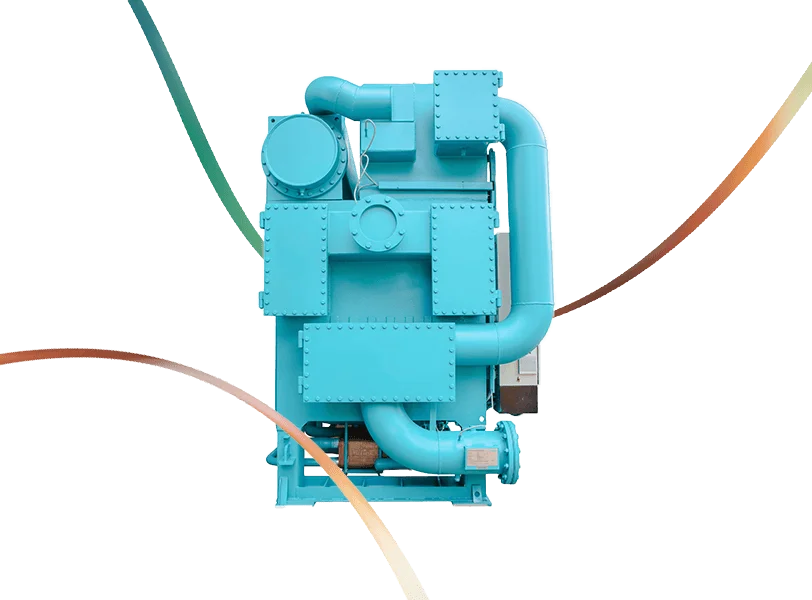

Steam Driven Vapour Absorption Chillers - KPCL

Sub Product Data Content (Steam Driven Vapour Absorption Chillers)

Capacity:

50 to 2000 TR

Capacity:

50 to 2000 TR

Type:

Why Kirloskar Pneumatic?

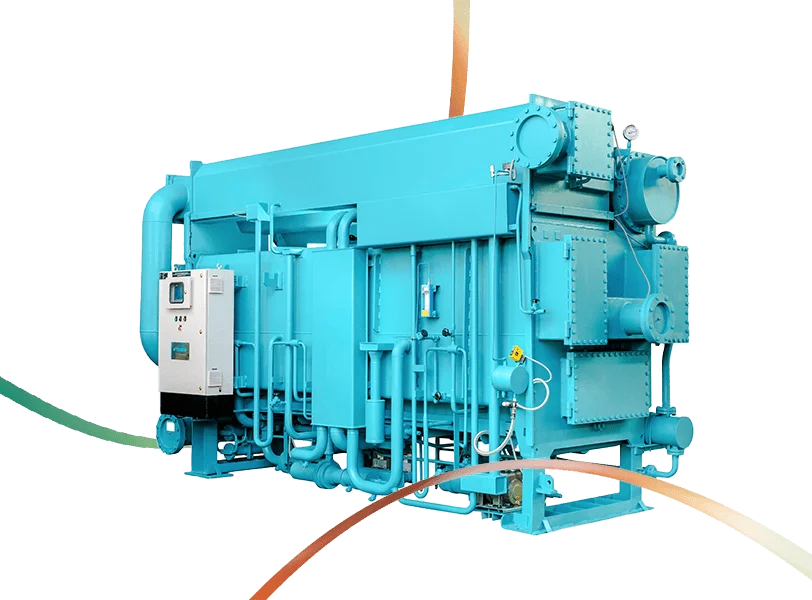

Kirloskar Pneumatic’s Steam Driven Vapour Absorption Chillers offer a versatile, energy-efficient, and environmentally friendly cooling solution. Their capability to operate at a wide range of steam pressures makes them suitable for diverse industrial applications. With their advanced technology and robust design, these chillers provide reliable and cost-effective cooling, turning waste heat into a valuable resource while setting new standards in industrial refrigeration.

FEATURES

- Can operate at steam pressures as low as 0.5 kg/cm².

- These chillers effectively turn waste heat into a valuable cooling resource.

- Steam-driven absorption chillers use water as the refrigerant and lithium bromide (LiBr) as the absorbent.

- The reliable and robust design ensures they withstand rigorous industrial environments..

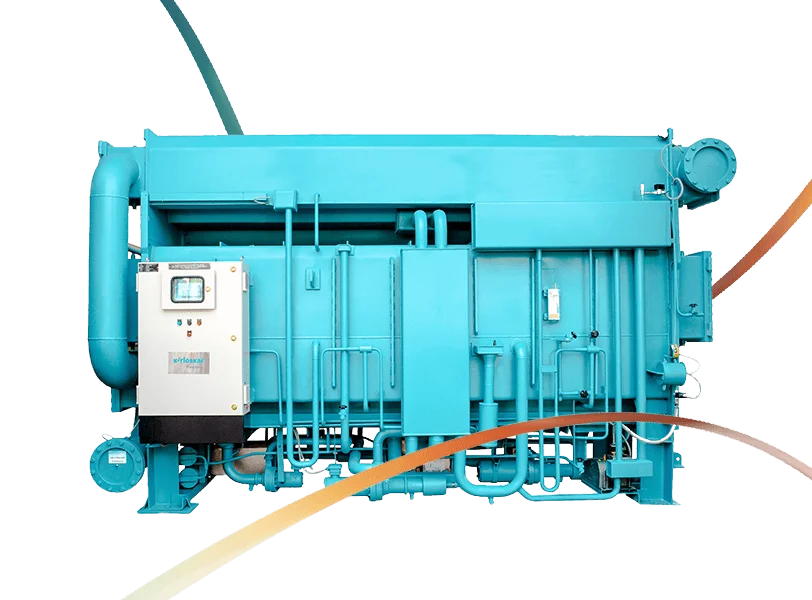

- Equipped with advanced PLC-based control systems, these chillers offer precise control over the cooling process.

BENEFITS

- Wide Operating Range: The ability to operate at steam pressures as low as 0.5 kg/cm² allow these chillers to be used in various settings, from facilities with low-pressure steam availability to those with high-pressure steam systems.

- Energy Efficiency: By utilising steam, a by-product or primary energy source in many industrial processes, these chillers optimise energy use and significantly reduce operational costs.

- Environmentally Friendly: Our steam-driven absorption chillers use water as the refrigerant and lithium bromide (LiBr) as the absorbent. Both these are environmentally benign compared to traditional refrigerants, making our chillers an eco-friendly cooling solution.

- Cost-Effective Operation: The use of steam, especially when sourced from industrial waste heat, can lead to substantial cost savings. The low operational costs make these chillers an economically attractive option for large-scale cooling needs.

- Reliable and Robust Design: Their robust construction ensures long-term reliability and minimal maintenance requirements.

- Advanced Control Systems: Equipped with advanced PLC-based control systems, these chillers offer precise control over the cooling process. The user-friendly interface ensures easy operation and monitoring.

Why Kirloskar Pneumatic?

Kirloskar Pneumatic’s Steam Driven Vapour Absorption Chillers offer a versatile, energy-efficient, and environmentally friendly cooling solution. Their capability to operate at a wide range of steam pressures makes them suitable for diverse industrial applications. With their advanced technology and robust design, these chillers provide reliable and cost-effective cooling, turning waste heat into a valuable resource while setting new standards in industrial refrigeration.

FEATURES

- Can operate at steam pressures as low as 0.5 kg/cm².

- These chillers effectively turn waste heat into a valuable cooling resource.

- Steam-driven absorption chillers use water as the refrigerant and lithium bromide (LiBr) as the absorbent.

- The reliable and robust design ensures they withstand rigorous industrial environments..

- Equipped with advanced PLC-based control systems, these chillers offer precise control over the cooling process.

BENEFITS

- Wide Operating Range: The ability to operate at steam pressures as low as 0.5 kg/cm² allow these chillers to be used in various settings, from facilities with low-pressure steam availability to those with high-pressure steam systems.

- Energy Efficiency: By utilising steam, a by-product or primary energy source in many industrial processes, these chillers optimise energy use and significantly reduce operational costs.

- Environmentally Friendly: Our steam-driven absorption chillers use water as the refrigerant and lithium bromide (LiBr) as the absorbent. Both these are environmentally benign compared to traditional refrigerants, making our chillers an eco-friendly cooling solution.

- Cost-Effective Operation: The use of steam, especially when sourced from industrial waste heat, can lead to substantial cost savings. The low operational costs make these chillers an economically attractive option for large-scale cooling needs.

- Reliable and Robust Design: Their robust construction ensures long-term reliability and minimal maintenance requirements.

- Advanced Control Systems: Equipped with advanced PLC-based control systems, these chillers offer precise control over the cooling process. The user-friendly interface ensures easy operation and monitoring.