Reciprocating Engineered Set | Kirloskar Pneumatic - KPCL

Sub Product Data Content (Engineered Reciprocating RP ACR)

Capacity:

5 to 500 TR

Temperature:

-45°C to 5°C

Type:

Why Kirloskar Pneumatic?

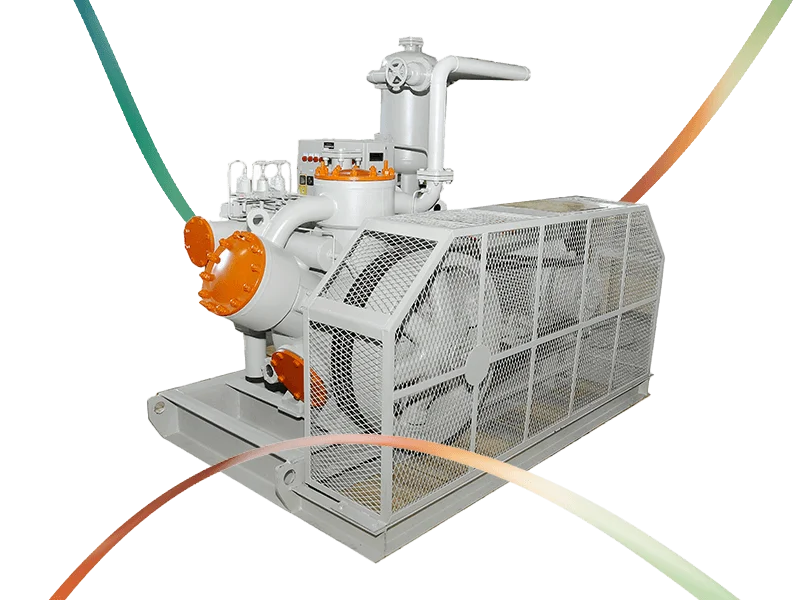

The Kirloskar Pneumatic reciprocating engineered sets are custom-made to maximise the refrigeration efficiency and reliability to meet various demanding industrial applications. With advanced features for higher efficiency, robust in construction and versatile, the reciprocating engineered sets are built to be compatible with different refrigerants. Factory assembled and aligned skid, they are available in direct drive and belt drive options coupled with a motor.

Features

- Factory Assembled and Aligned Skid: Pre-engineered and precisely assembled for quick deployment and minimal installation effort.

- Plug and Play Package for Easy Installation: Simplifies commissioning with a ready-to-use setup.

- Custom Designed for Each Application: Engineered to meet specific cooling demands across diverse industries.

- Integrated Automation through KRMS: Advanced control system for real-time monitoring, predictive maintenance, and efficiency optimization.

- Oil Return Line with Check Valve and Filter: Enhances lubrication, improving performance and extending compressor life.

Benefits

- Fast and Hassle-Free Installation: Factory-aligned design reduces setup time and ensures precise operation.

- Optimised Performance Efficiency: KRMS-driven automation maximizes energy savings and enhances system reliability.

- Application-Specific Customization: Designed to meet the unique refrigeration needs of different industries.

- Low Maintenance Extended Durability: Smart oil management and high-quality construction ensure long service life with minimal upkeep.

Why Kirloskar Pneumatic?

The Kirloskar Pneumatic reciprocating engineered sets are custom-made to maximise the refrigeration efficiency and reliability to meet various demanding industrial applications. With advanced features for higher efficiency, robust in construction and versatile, the reciprocating engineered sets are built to be compatible with different refrigerants. Factory assembled and aligned skid, they are available in direct drive and belt drive options coupled with a motor.

Features

- Factory Assembled and Aligned Skid: Pre-engineered and precisely assembled for quick deployment and minimal installation effort.

- Plug and Play Package for Easy Installation: Simplifies commissioning with a ready-to-use setup.

- Custom Designed for Each Application: Engineered to meet specific cooling demands across diverse industries.

- Integrated Automation through KRMS: Advanced control system for real-time monitoring, predictive maintenance, and efficiency optimization.

- Oil Return Line with Check Valve and Filter: Enhances lubrication, improving performance and extending compressor life.

Benefits

- Fast and Hassle-Free Installation:Factory-aligned design reduces setup time and ensures precise operation.

- Optimised Performance Efficiency: KRMS-driven automation maximizes energy savings and enhances system reliability.

- Application-Specific Customization:Designed to meet the unique refrigeration needs of different industries.

- Low Maintenance Extended Durability:Smart oil management and high-quality construction ensure long service life with minimal upkeep.