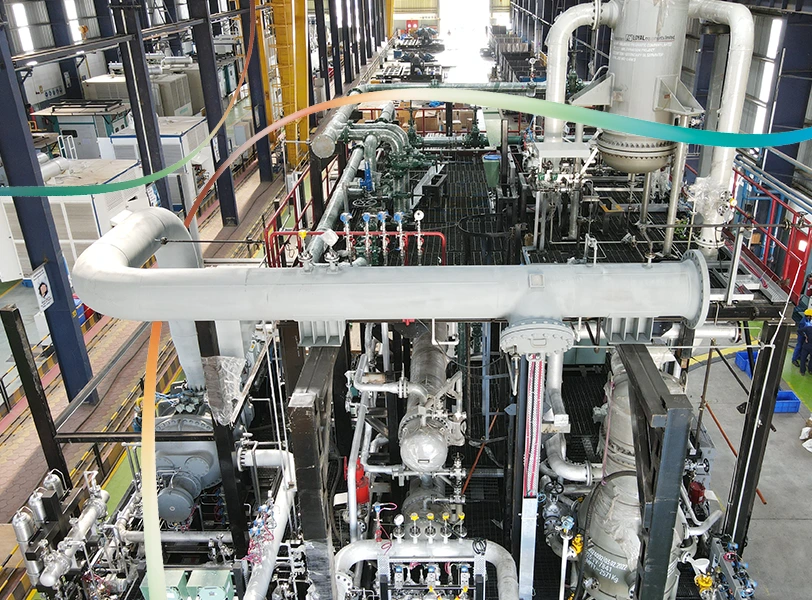

Screw Gas Compressor Package - KPCL

Sub Product Data Content (Screw Compressor Packages)

Pressure Range:

1 to 32 bar

Gas Flow:

100 to 6000 CFM

Why Kirloskar Pneumatic?

Kirloskar Pneumatic is the authorised packager for Howden UK. These compressors are oil flooded screw compressors API 619 compliant. Oil-flooded screw gas compressors are a crucial technology in the oil and gas industry, known for their ability to handle a wide range of gases under various operating conditions. These compressors use oil to seal, cool, and lubricate the compression process, enhancing efficiency and reliability. They are especially suited for applications requiring high efficiency, low noise, and robust performance in challenging environments.

Features

- Wide Pressure Range: Handles 1 to 32 bar, suitable for diverse industrial needs.

- High Gas Flow: Manages 100 to 6000 CFM for efficient operation.

- Optimised for consistent performance across varying pressures and flows.

- Durable: Built for tough conditions, ensuring long-term reliability.

- Low Maintenance: Requires minimal upkeep, ensuring higher uptime.

- Compliance: Meets API, ASME, and ASTM standards for quality and safety.

- Oil Injection: Oil is injected into the compression chamber, which not only seals the gaps between the rotors but also cools the gas during compression, allowing for higher compression ratios and increased efficiency.

- High Efficiency: The oil-flooded design reduces internal leakage and provides better cooling, resulting in higher efficiency compared to dry screw compressors.

- Robust Construction: Built to withstand harsh conditions, including exposure to corrosive gases and high-pressure environments typical in the oil and gas sector.

- Low Noise and Vibration: The oil in the system acts as a dampener, significantly reducing noise and vibration, making these compressors suitable for noise-sensitive applications.

- Integrated Oil Separation: Equipped with efficient oil separation systems to ensure that the compressed gas is delivered with minimal oil content, which is then recycled back into the system.

- Advanced Control Systems: Includes sophisticated controls for monitoring and optimising compressor performance, ensuring reliable operation and energy efficiency.

Benefits

- Engineered to deliver consistent performance in diverse and challenging conditions, with a focus on durability and long-term reliability.

- Designed and fabricated according to API, ASME, and ASTM standards, with comprehensive design and simulation tools ensuring optimal functionality.

- Low maintenance needs and high package uptime reduces overall operational costs.

- Equipped with effective pulsation suppression devices to maintain low noise levels and smooth operation.