Compressed Biogas Applications - KPCL

Sub Product Data Content (Compressed Biogas Applications)

Type:

Why Kirloskar Pneumatic?

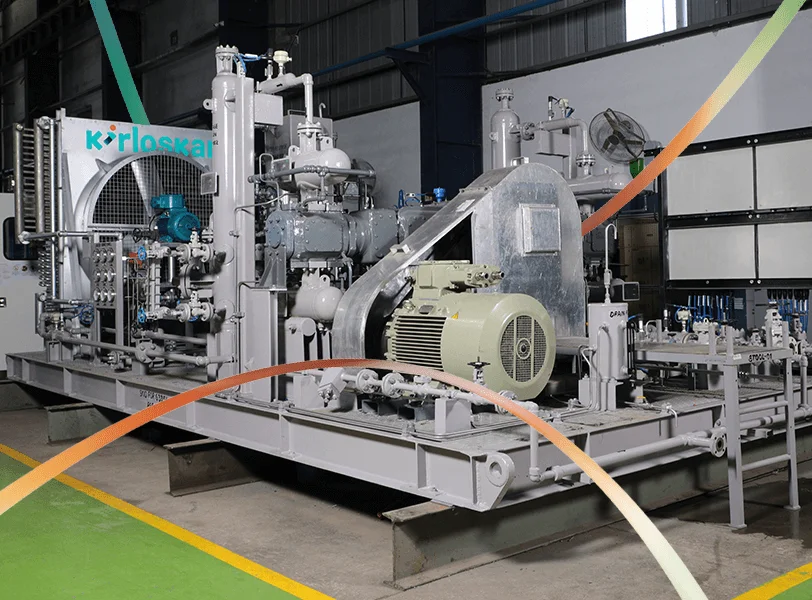

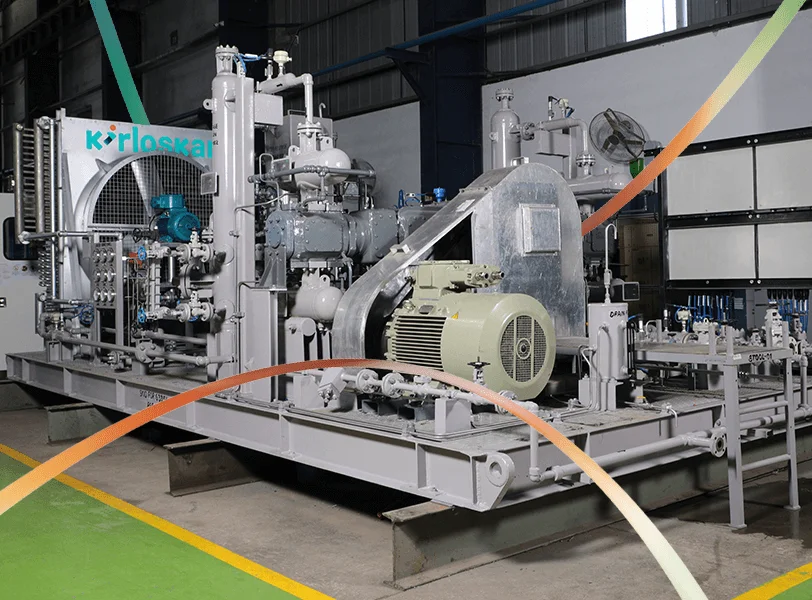

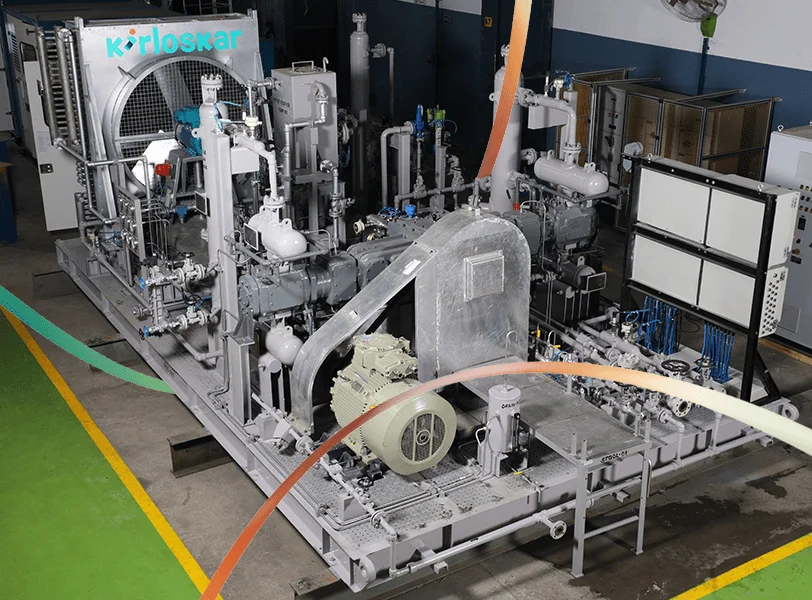

With years of experience in the oil and gas industry, we have a proven record for bringing unparalleled expertise to the biogas sector. Our Jarilo Low Pressure Compressors are engineered to handle the initial stages of biogas processing with ease and precision. Capable of compressing raw biogas, these models are ideal for feeding gas into water scrubbers, PSA and membrane purification systems. They efficiently feed gas into CO2 scrubbers, even at low suction pressures.

IoT enabled, the unique microprocessor-based panel provides machine parameters, data log management, remote management, service alerts, service management, predictive analysis, complementing our comprehensive support that ensures full service 24x7 to a biogas plant. Built entirely in-house, ensures right time delivery as all critical components proudly carry the Kirloskar name.

Features

- It is integrated with purification technologies to seamlessly work with water scrubbers and membrane technologies for effective biogas purification.

- It is optimised for raw biogas. All wetted parts are made of SS 304, providing durability and corrosion resistance. They are even capable of withstanding the presence of CO2 in raw biogas.

- Designed to operate efficiently with suction pressure as low as 0.147 kg/cm2G.

- Utilises a V-belt drive arrangement for reliable power transmission.

- Ensures effective cooling for enhanced compressor performance.

- Offers 0-100% capacity control to manage uneven gas flow effectively.

- The robust construction with the self-lubricating piston and rider rings as well as the ribbed crankcase for heavy duty operations and a longer duty cycle.

Benefits

- Capable of handling low suction pressures, ensuring smooth operation in various conditions.

- SS 304 wetted parts and V-belt drive enhance longevity and operational reliability.

- The water-cooled heat exchanger maintains optimal temperatures, increasing compressor efficiency.

- Full range capacity control allows for precise adjustment to varying flow rates, ensuring consistent output.

Why Kirloskar Pneumatic?

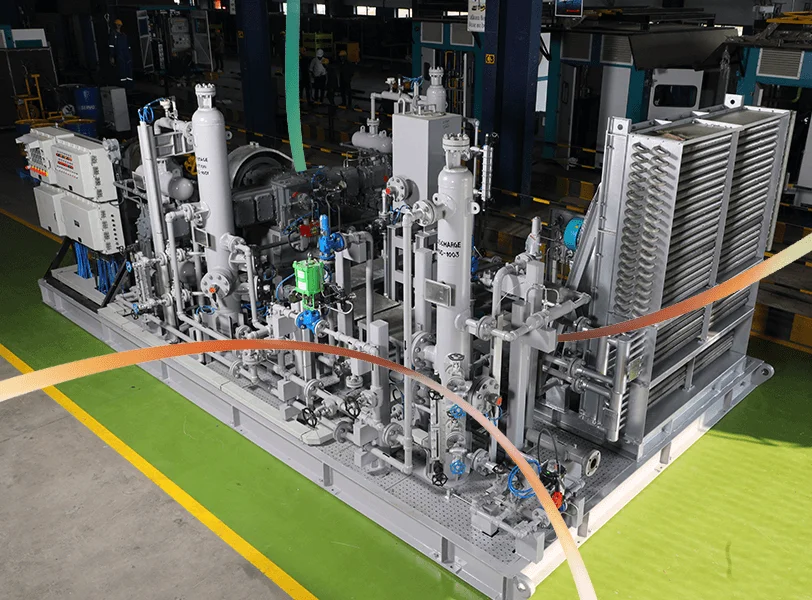

With years of experience in the oil and gas industry, we have a proven record for bringing unparalleled expertise to the biogas sector. Tailored in compliance with industry standards, our Jarilo High Pressure Compressors are best suited for applications that require higher pressures. These models can achieve pressures up to 250 bar, making them suitable for a range of advanced biogas applications, including cascade filling. With advanced features like direct power transfer, air-cooled operation, and flexible capacity control, they offer efficient and reliable performance for demanding high-pressure environments.

IoT enabled, the unique microprocessor based panel provides machine parameters, data log management, remote management, service alerts, service management, predictive analysis, complementing our comprehensive support that ensures full service 24x7 to a biogas plant. Built entirely in-house, ensures right time delivery as all critical components proudly carry the Kirloskar name.

Features

- With high pressure capability, they operate with a suction pressure of 7.5 kg/cm2G for demanding applications.

- Provides a direct and efficient power transfer, reducing energy losses.

- Ensures effective cooling without the need for additional water systems.

- With precision engineering, they offer 0-40% capacity control to ensure consistent and reliable performance for variable gas flow.

- We adhere to industry standards of robust construction to handle high-pressure operations safely and efficiently.

Benefits

- Capable of reaching a discharge pressure of 255 kg/cm2G, making it ideal for Bio CNG stations and cascade filling.

- Direct coupled drive reduces energy consumption, improving overall efficiency.

- Air-cooled heat exchanger simplifies maintenance, eliminating the need for water handling.

- Capacity control ensures the compressor can handle fluctuating flow rates, maintaining consistent performance.