Screw Gas Compressor Package - Kirloskar Pneumatic

Gas Compression Systems

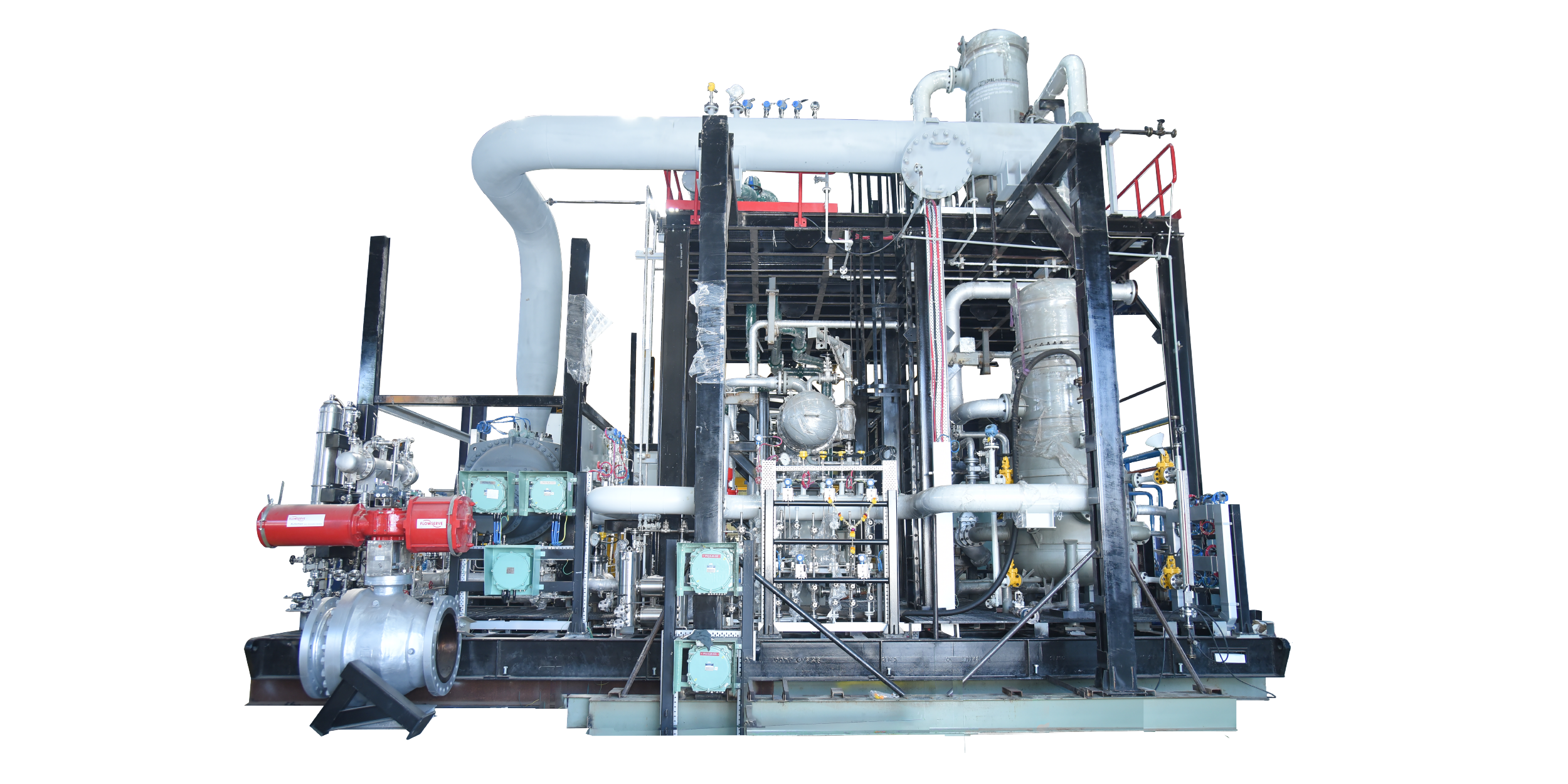

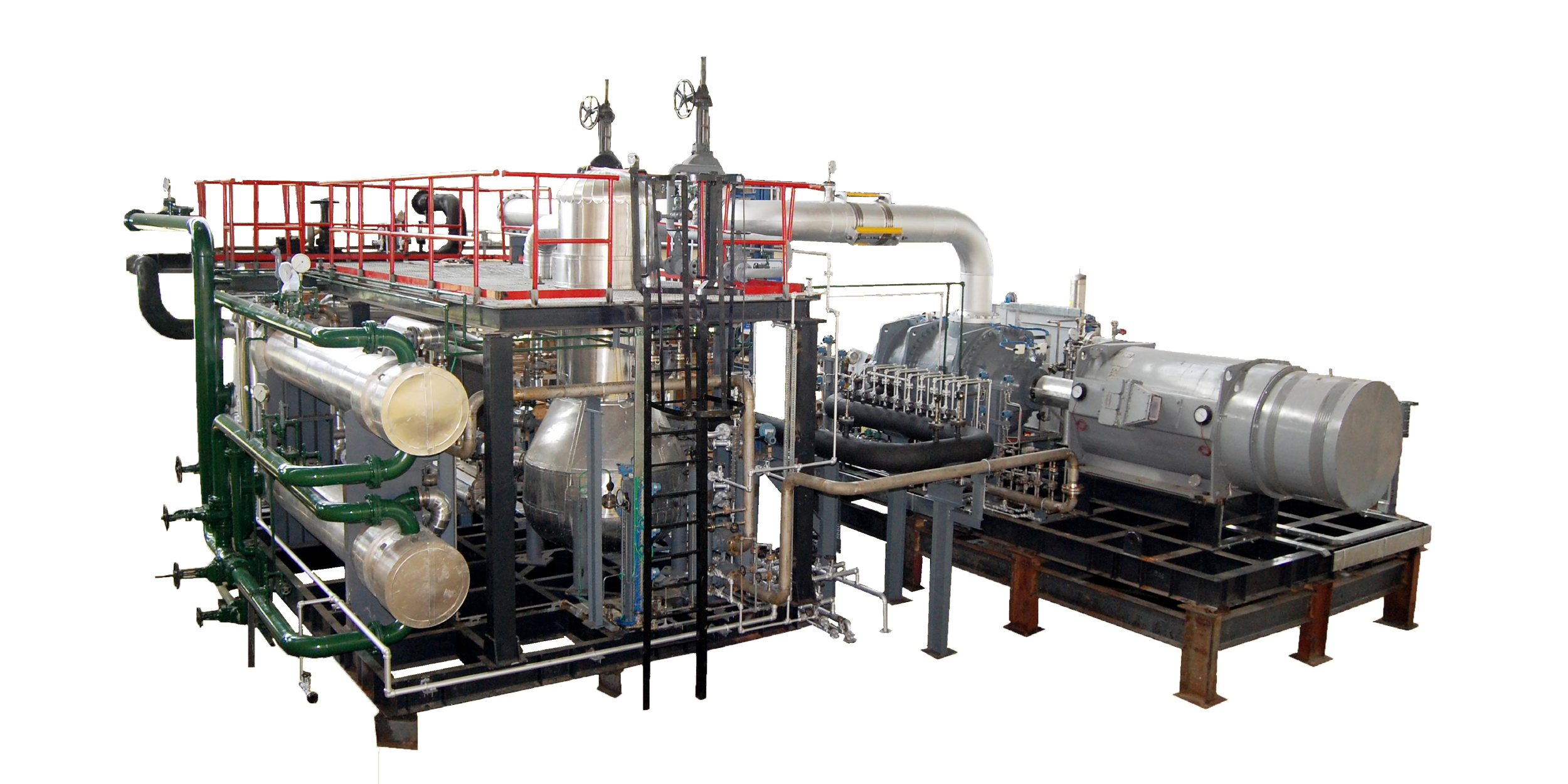

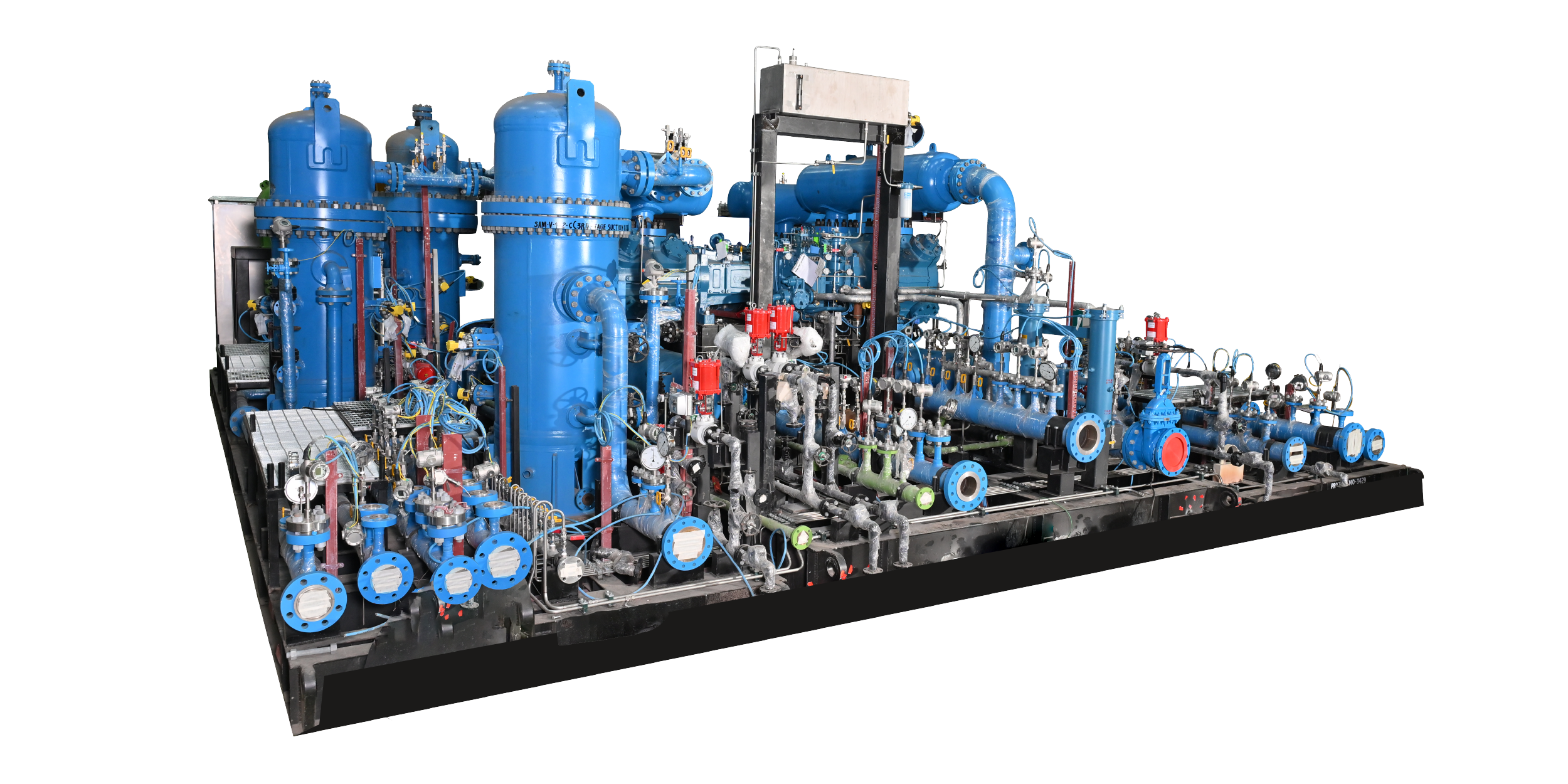

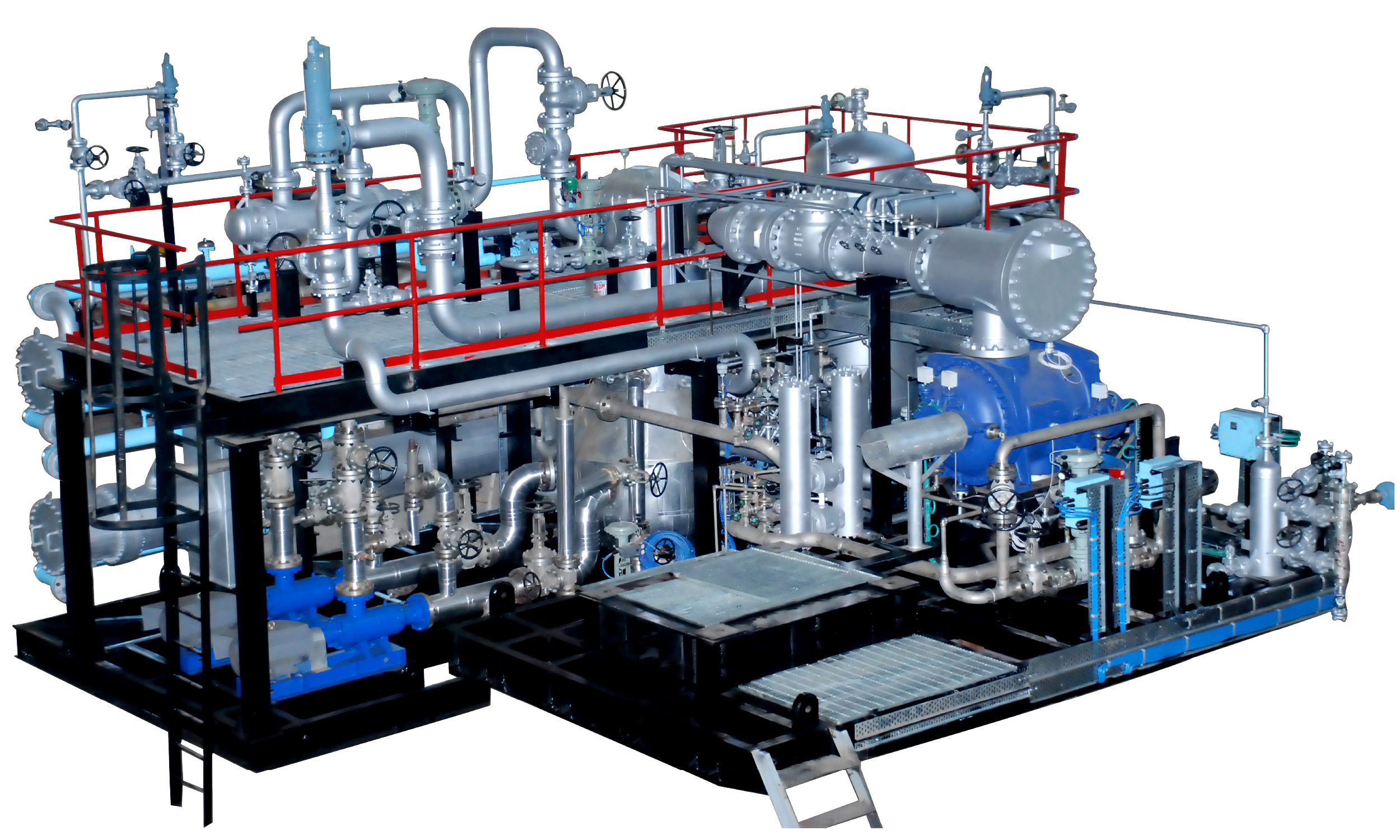

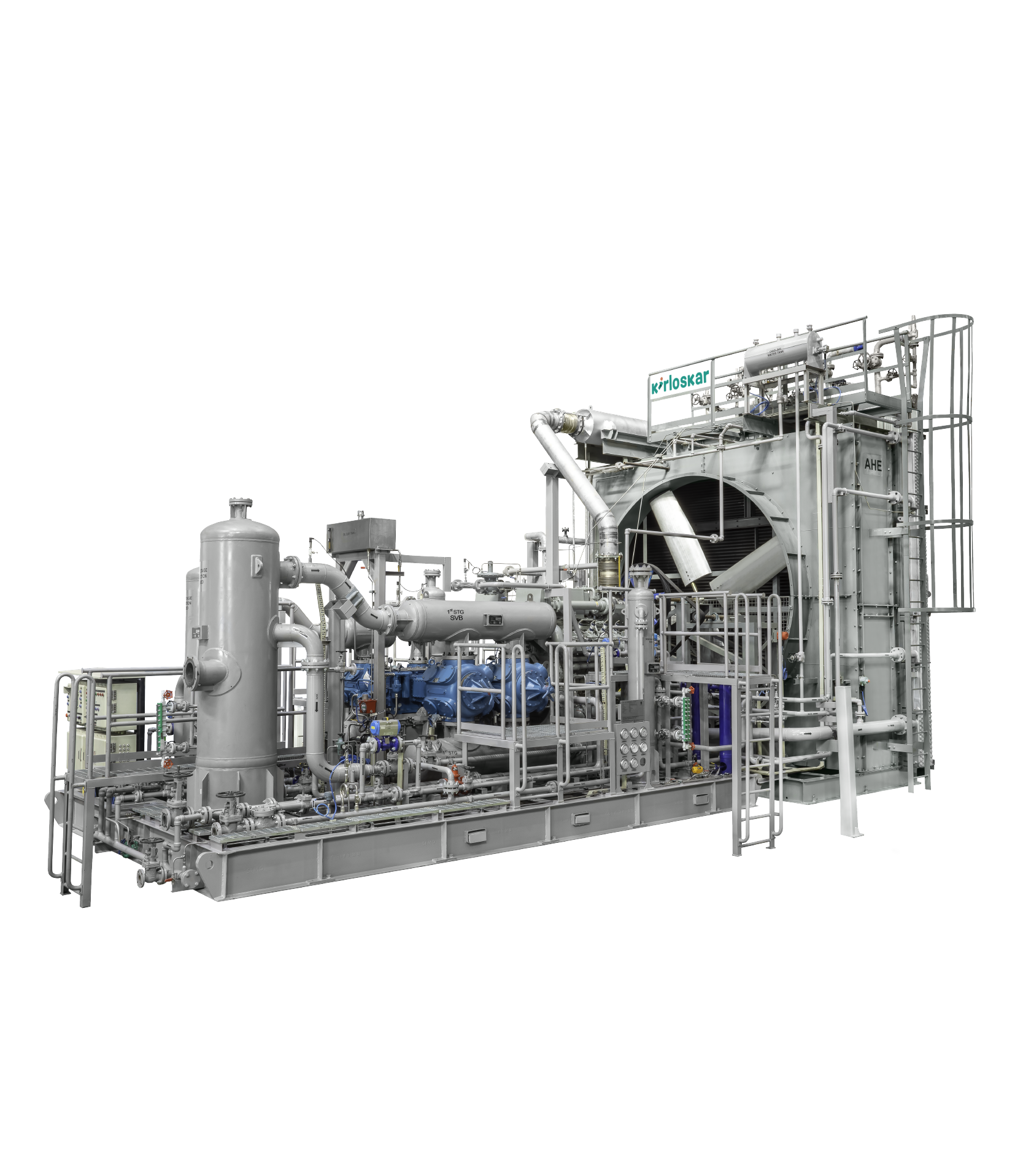

Screw Gas Compressor Package

Screw compressors are vital in the oil and gas industry, known for their ability to handle large volumes of gas at relatively low to medium pressures. These compressors are particularly valued for their efficiency, reliability, and low maintenance needs, making them ideal for various applications across the upstream, midstream, and downstream sectors.

KPCL is the authorised packager for Howden UK. These compressors are oil flooded screw compressors API 619 compliant. Oil-flooded screw gas compressors are a crucial technology in the oil and gas industry, known for their ability to handle a wide range of gases under various operating conditions. These compressors use oil to seal, cool, and lubricate the compression process, enhancing efficiency and reliability. They are especially suited for applications requiring high efficiency, low noise, and robust performance in challenging environments.

1. Upstream Sector

- Gas Gathering: Screw compressors are used to collect gas from multiple wells and boost its pressure for transport to processing facilities. Their ability to handle fluctuating flow rates makes them suitable for this application.

- Vapor Recovery: In oil production, screw compressors are used in vapor recovery units (VRUs) to capture and compress gas vapors released during oil storage and handling, preventing emissions and enabling the recovery of valuable hydrocarbons.

2. Midstream Sector

- Pipeline Compression: Screw compressors are used to boost the pressure of natural gas in pipelines, ensuring efficient transportation over long distances. They are especially useful in scenarios where gas flows at lower pressures and higher volumes.

- Gas Processing: In gas processing plants, screw compressors are employed for tasks such as gas sweetening, where they help compress and circulate gases through absorbers and strippers to remove impurities like hydrogen sulfide and carbon dioxide.

- Refrigeration Systems: Screw compressors are integral in refrigeration systems used in natural gas processing, where they compress refrigerants in gas-liquid separation processes.

3. Downstream Sector

- PSA tail gas compression: Screw compressor packages are used for compressing the PSA tail gas and reinjecting it into the process, to maximize hydrogen recovery and reduce waste, improving overall efficiency.

- Flare Gas Recovery: Screw compressors are used in flare gas recovery systems to compress gases that would otherwise be flared, reducing emissions and enabling the reuse of these gases within the plant.

- Oil Injection: Oil is injected into the compression chamber, which not only seals the gaps between the rotors but also cools the gas during compression, allowing for higher compression ratios and increased efficiency.

- High Efficiency: The oil-flooded design reduces internal leakage and provides better cooling, resulting in higher efficiency compared to dry screw compressors.

- Robust Construction: Built to withstand harsh conditions, including exposure to corrosive gases and high-pressure environments typical in the oil and gas sector.

- Low Noise and Vibration: The oil in the system acts as a dampener, significantly reducing noise and vibration, making these compressors suitable for noise-sensitive applications.

- Integrated Oil Separation: Equipped with efficient oil separation systems to ensure that the compressed gas is delivered with minimal oil content, which is then recycled back into the system.

- Advanced Control Systems: Includes sophisticated controls for monitoring and optimizing compressor performance, ensuring reliable operation and energy efficiency.

- Wide Range of Capacities: Available in various sizes and capacities to meet different application needs, from small-scale operations to large industrial installations.