Kirloskar Ultra Efficient Vapour Absorption Chillers - Kirloskar Pneumatic

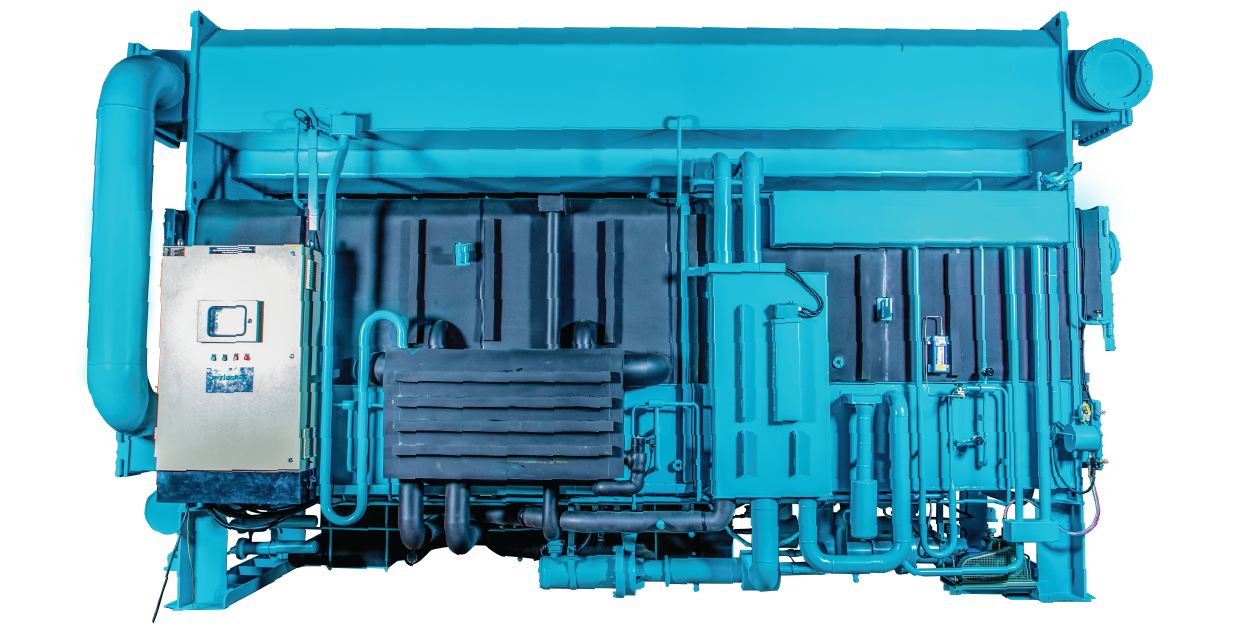

Vapour Absorption Chillers

Kirloskar Ultra Efficient Vapour Absorption Chillers – Delivers Promised Performance

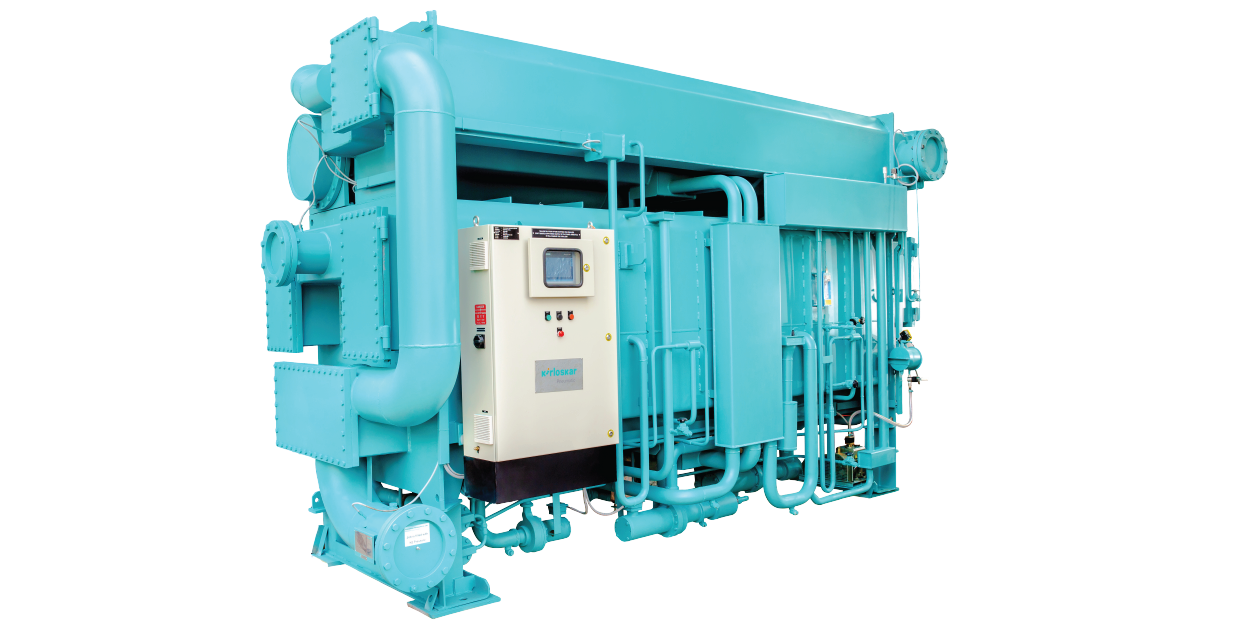

- No Blow-down: Eliminates the need for blow-down, enhancing system efficiency and reducing maintenance requirements.

- No LiBr Top-Up Required: Operates without the need for frequent LiBr (lithium bromide) solution top-ups, simplifying operation and reducing downtime.

- No Crystallization: Advanced design prevents crystallization, ensuring consistent performance and reliability.

- No Tuning Required: The system operates without the need for manual tuning, offering hassle-free performance.

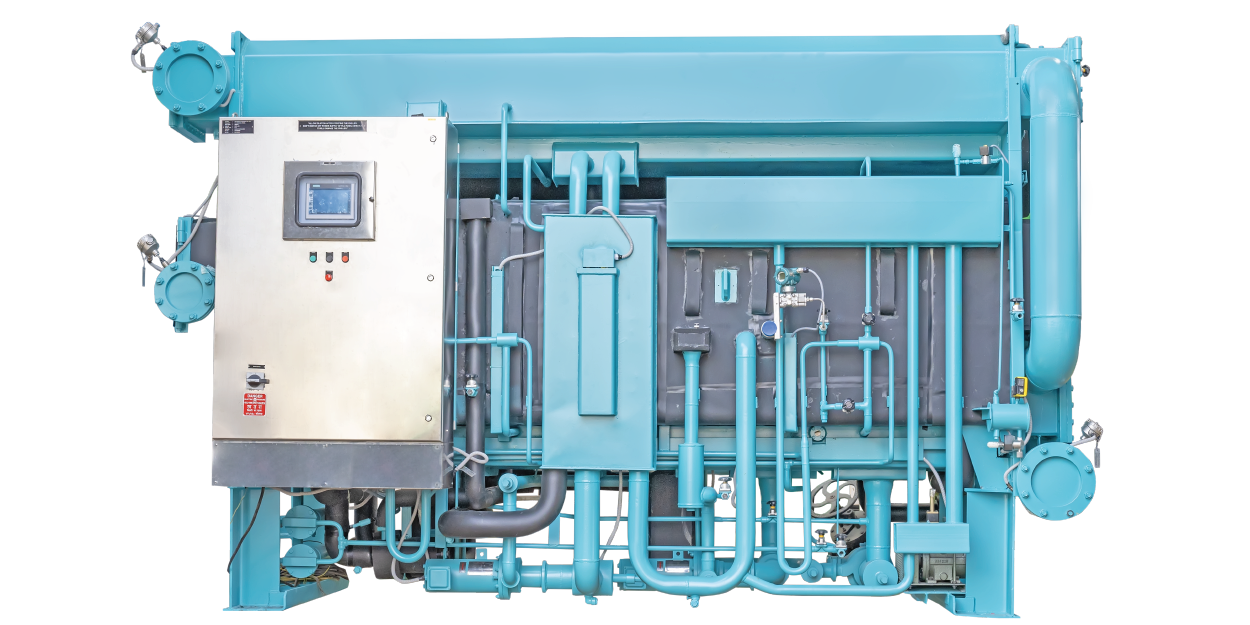

"Hands-Free" and Reliable:

- Automatic Purging: Features automatic purging without the need for operator intervention.

- In-Built Li-Br Solution Filter: Includes a built-in Li-Br solution filter to ensure clean operation.

- No Corrosion: Constructed with materials that prevent corrosion, enhancing durability and lifespan.

- Advanced PLC-Based Control Panel: Equipped with a touch screen MMI (Man-Machine Interface) for intuitive control and monitoring.

Kirloskar’s Ultra Efficient Vapour Absorption Chillers represent a leap forward in absorption chiller technology, combining cutting-edge features with superior performance to meet the most demanding industrial needs.

Product Specifications

Single Effect Steam Driven Vapour Absorption Chiller

- Capacity: 50 – 2000 TR

- Heat Source: Steam

- Steam Pressure: 0.5 – 3.0 kg/cm2(g)

- COP: 0.75

Double Effect Steam Driven Vapour Absorption Chiller

- Capacity: 50 – 2000 TR

- Heat Source: Steam

- Steam Pressure: 3.5 – 8.0 kg/cm2(g)

- COP: 1.5

Product Specifications

Double Lift Hot Water Driven Vapour Absorption Chiller

- Capacity: 50 – 1000 TR

- Heat Source: Hot Water

- Hot Water Temperature: 700c

- COP: 0.41 to 0.71

Single Effect Hot Water Driven Vapour Absorption Chiller

- Capacity: 50 – 1500 TR

- Heat Source: Hot Water

- Hot Water Temperature: 80 – 1200c

- COP: 0.75

Double Effect Hot Water Driven Vapour Absorption Chiller

- Capacity: 50 – 1500 TR

- Heat Source: Hot Water

- Hot Water Temperature: 160 – 1800c

- COP: 1.5

Product Specifications

Composite Chiller

- Capacity: 25 – 200 TR

- Brine Temperature: -35 to -5 °C

- Refrigerant: R404, R134a, Ammonia

- Heat Source: Steam / Hot Water / Exhaust Gas / Fuel

Zero Degree Vapour Absorption Chillers

- Capacity: 50 – 1000 TR

- Heat Source: Steam / Hot Water / Exhaust Gas / Fuel

Chiller + Hot Water Generator

- Cooling Capacity: 50 – 2000 TR

- Heating Capacity: 130 – 5275 kW

- Heat Source: Steam / Hot Water / Exhaust / Fuel

Ultra Low Pressure Vapour Absorption Chiller

- Capacity: 50 – 1000 TR

- Heat Source: CP Vapour / Ultra Low Pressure Steam

- Steam Pressure: <0.5 kg/cm2

(g)

Kirloskar’s non-standard vapour absorption chillers provide a versatile, energy-efficient, and environmentally friendly solution for industrial and process cooling applications. By offering customized solutions tailored to the specific needs of each application, these chillers ensure optimal performance and reliability. With advanced features and robust design, Kirloskar’s non-standard vapour absorption chillers set new benchmarks for efficiency and sustainability in industrial refrigeration.

- Pulp & Paper

- Chemical & Fertilizers

- Food Processing

- Breweries and Beverages

- Metals

- Oil & Gas

- Dairy

- Pharmaceuticals

- Textile

- Power

Enquiry

PRODUCTS