Air Compressors - Kirloskar Pneumatic

Air Compressor

Service

The Air Compressors division of ACD has been in operation since 1958 and has the longest standing history in the domestic market. There are thousands of Air Compressors that have been serving their customers efficiently for many dedicated years. These compressors have a simple and easily laid out plan for service and maintenance.

The screw compressors are installed using a comprehensive manual that covers Receipt of Compressors, Handling of Compressors, Compressor Storage, Installation Protocol, Room Ventilation, Layout and Air Piping Guidelines, Drains and Electrical connection points, Electrical Connections, Waste Disposal and Care contacts. Each of these machines are meant to operate under certain ambient conditions and it is recommended that the manual is followed not only for installation but also for further starting and continued use of the compressor.

Each of these machines are operating under continuous loads and variable input power conditions. To ensure that they perform efficiently and without failure the right lubricating oil is needed to ensure that breakdowns do not occur. KPCL offers K – SMART (Systematic Measurable Accessible Reliable and Time Bound) grade of synthetic lubricant oil which is tailored to meet the specific requirements of the Electric Screw Compressors. Its special formulation yields top performance and maximum lifetime of all moving parts.

Air Audits are also an integral part of the process of service. Compressed air system energy audit [Air Audit] is an accurate process undertaken to identify areas of loss or inefficiencies within a compressed air system. With increasing energy costs a fact of life for business. These assessments are conducted and shared with a customer to identify and plug gaps in the system and formatively improve efficiency.

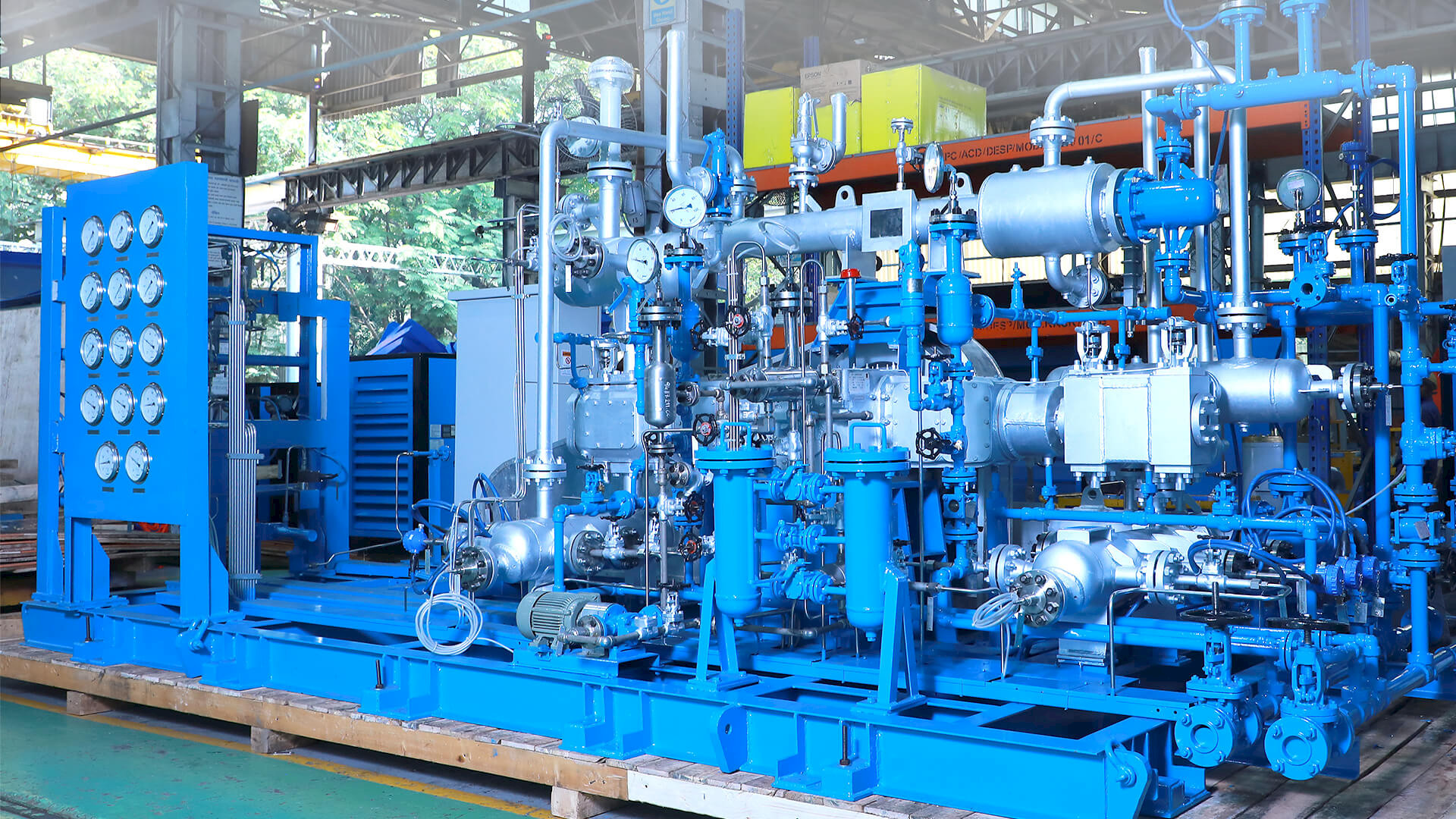

Centrifugal Air Compressors are a custom built machine and used on critical application projects. These machines are designed to work operate with minimal stoppage and continuous operations. The service schedule is based on number of running hours and each set up is offered with a two year spares package.